Hydraulic system for loading test

A hydraulic system and loading test technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, servo motor components, etc., can solve the problems of unstable test performance, difficult torque control, and complex control system, etc., to achieve Easy to change load, good control of loading torque, and stable test performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

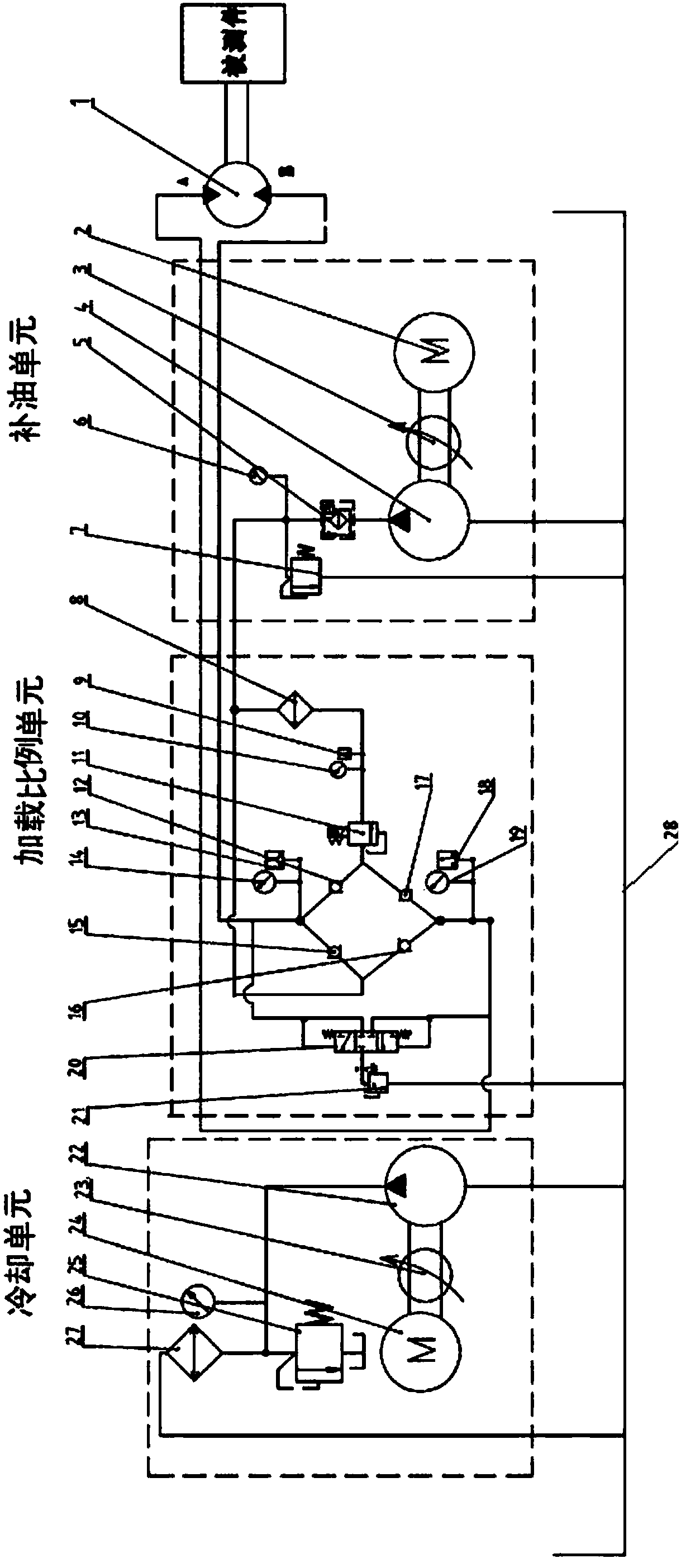

[0030] Such as figure 1 Shown is the schematic composition diagram of the hydraulic system of the present invention. The hydraulic system includes a motor 1, an oil supply unit, a load proportional unit, a low-pressure cooling unit and an oil tank.

[0031] Motor 1 is a variable displacement motor, used as a bi-directional pump, with two oil inlet and outlet ports (A oil inlet and outlet and B oil inlet and outlet), both of which are high-pressure oil ports, which can rotate in both directions and load in both directions. A fourth pressure gauge 19 and a third pressure sensor 18 are arranged on the A oil inlet and outlet pipeline, and a third pressure gauge 14 and a second pressure sensor 13 are arranged on the B oil inlet and outlet pipeline. During operation, the component under test (such as the output shaft of the gearbox) is connected with the shaft of the motor 1 .

[0032] The oil replenishment unit includes a first motor 2 , a first connecting piece 3 , a first oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com