Novel sand lime brick with fire-resistant effect

A lime-sand brick and refractory technology, applied in the field of lime-sand bricks, can solve the problems of low friction force of adjacent bricks, hidden dangers of production safety, low cohesion, etc., so as to improve heat exchange efficiency, reduce coal consumption, and improve installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

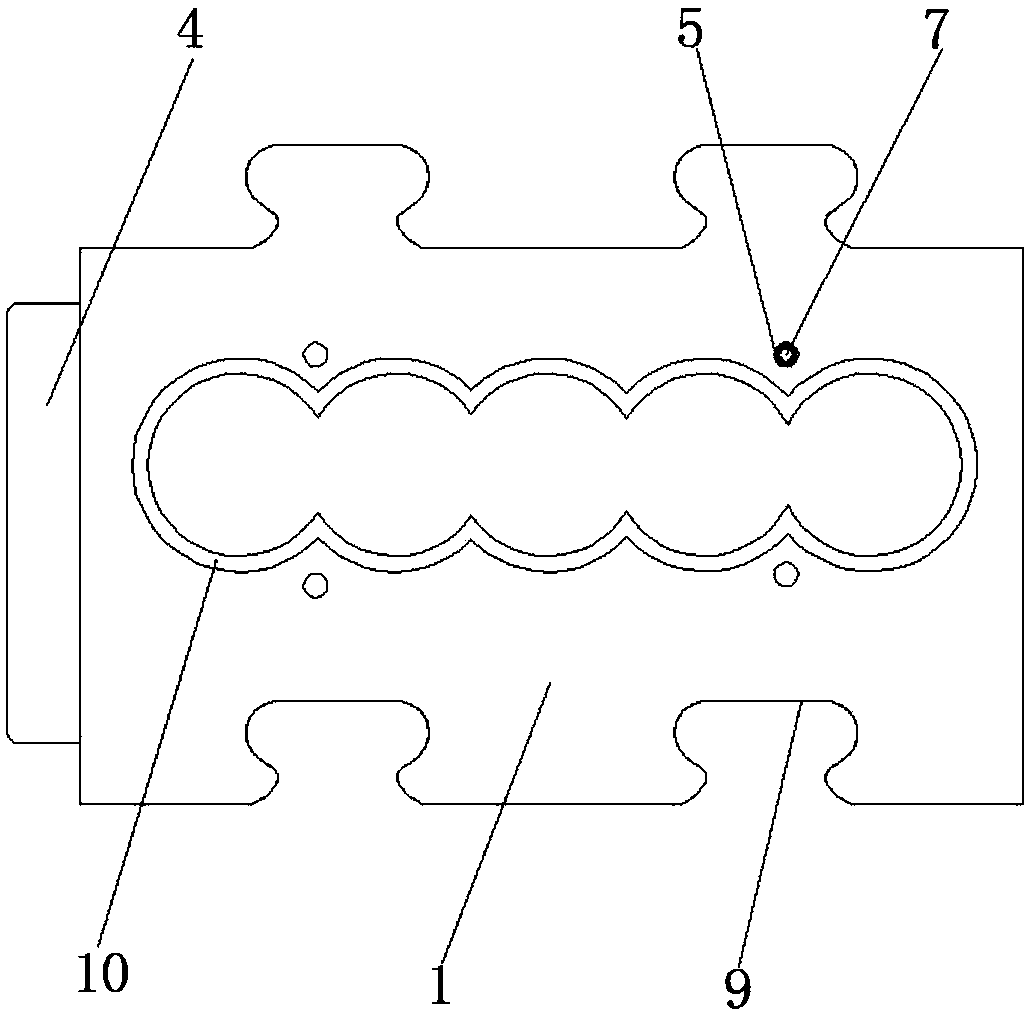

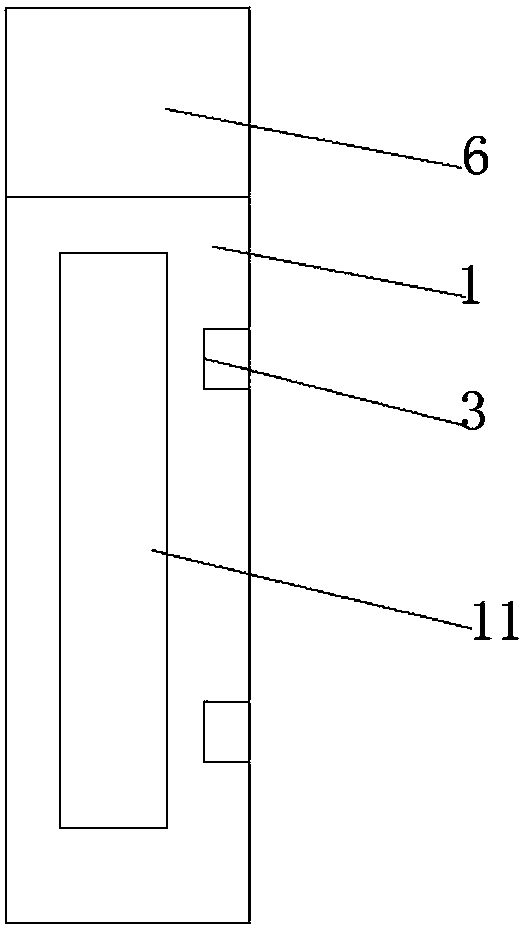

[0018] refer to Figure 1-4 , a new type of lime-sand brick with refractory effect, including a main brick body 1, a second brick body 12 and a third brick body 13, the main brick body 1 is a flat cuboid structure as a whole, and the main brick body 1 The positions near the two sides of the lower surface are respectively reserved with a first gap 2 and a second gap 9, and the first gap 2 and the second gap 9 are symmetrically distributed with respect to the vertical bisector in the length direction of the main brick body 1, and the main brick body 1 There are two bar-shaped grooves 3 across the two ends, and the two bar-shaped grooves 3 divide the front of the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com