Vertical washing trough

A water washing tank and vertical technology, which is applied in textiles and papermaking, liquid/gas/steam textile material treatment, spray/jet textile material treatment, etc. It can solve the problem of poor cleaning effect of cloth, floating cloth and failure to achieve continuous operation and other problems, to achieve the effect of improving the cleaning effect of the cloth, increasing the capacity of the cloth, and better washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

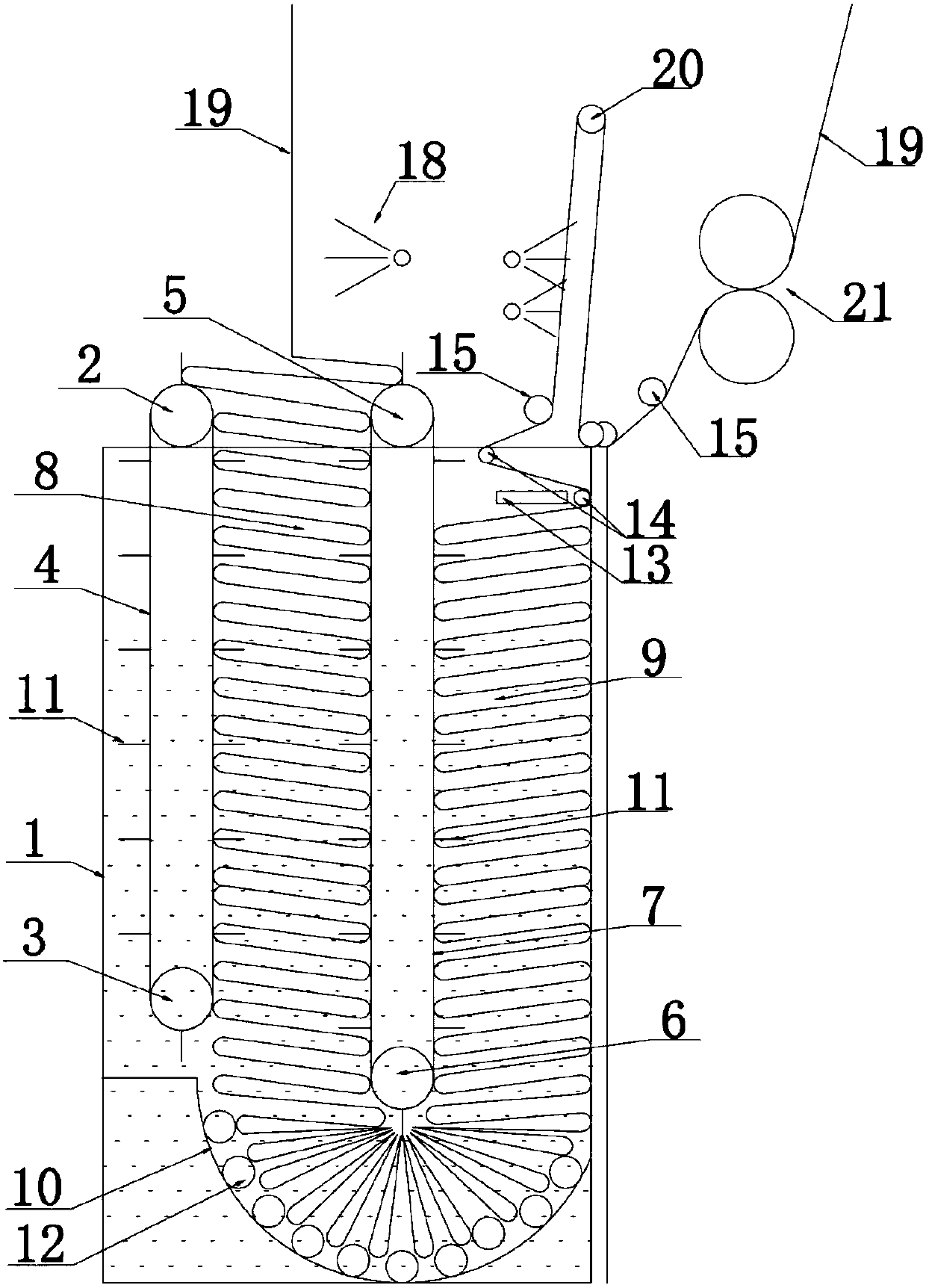

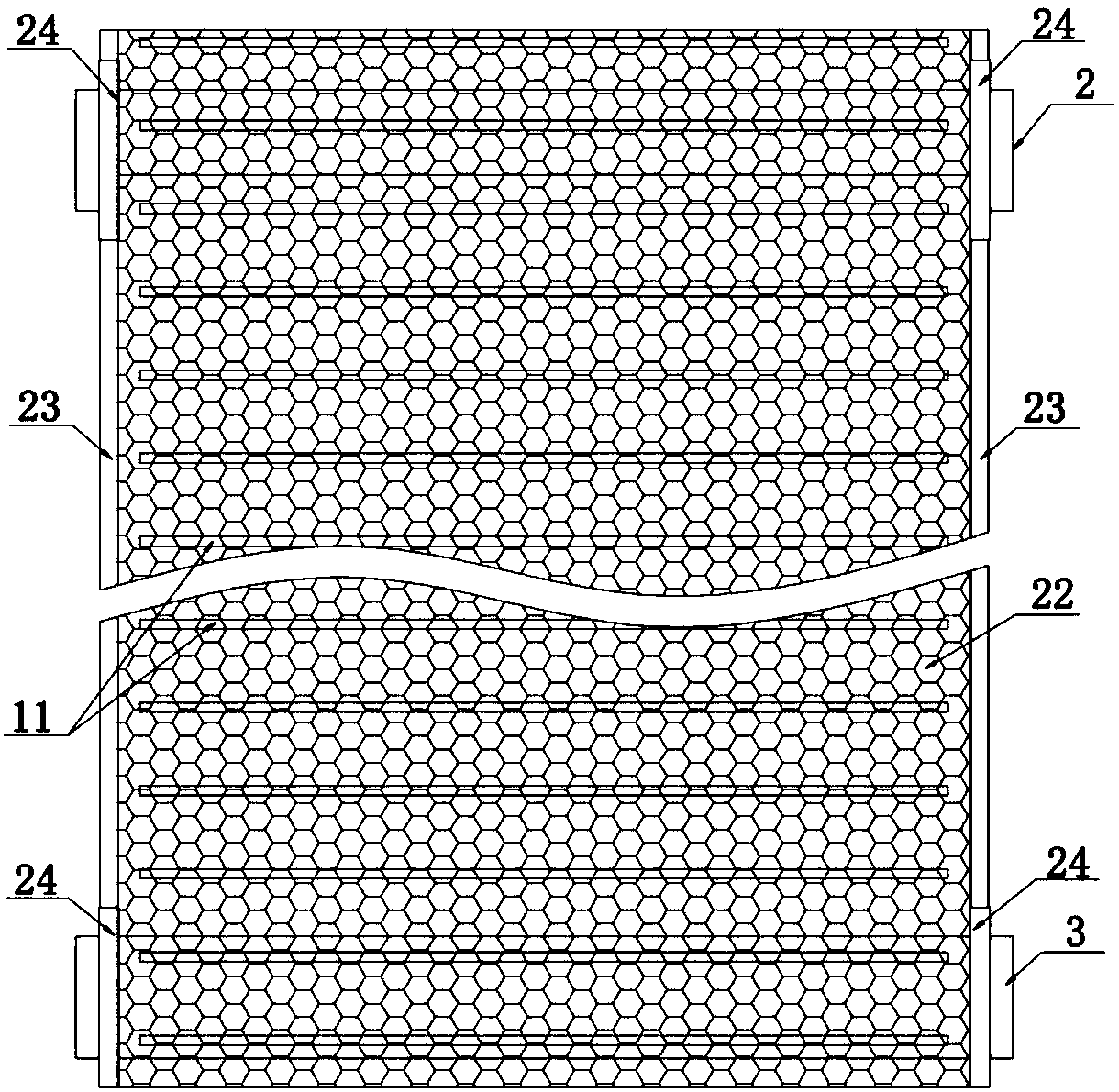

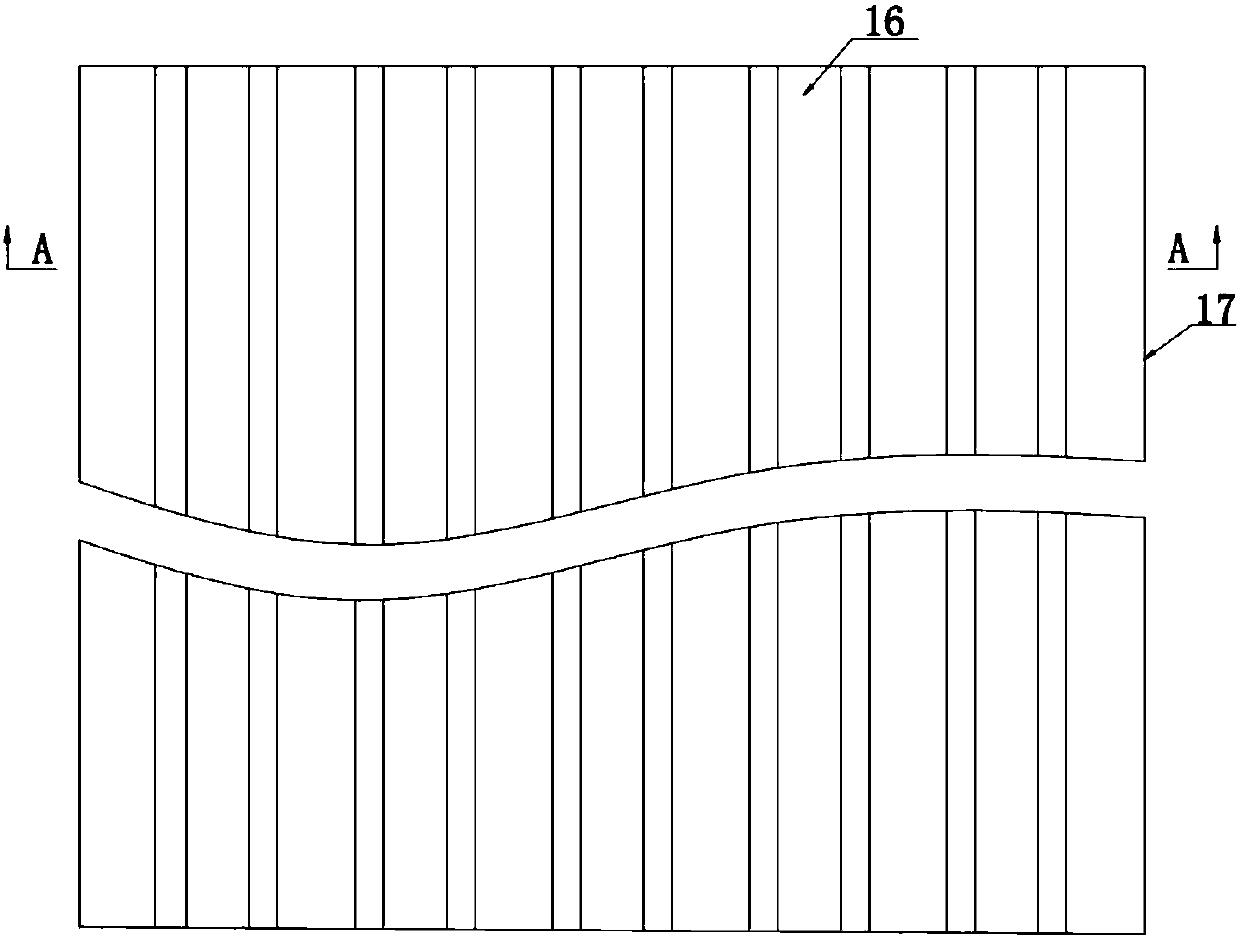

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0042] Such as Figure 1-Figure 9 As shown, a vertical water washing tank includes a rectangular tank body 1 with an upper opening, a left conveying mechanism, a right conveying mechanism and a guide mechanism, the left conveying mechanism is arranged on the left side of the rectangular tank body, and the left conveying mechanism The mechanism includes a left driving roller 2 and a left driven roller 3 arranged in parallel up and down, and a left conveyor belt 4 surrounds the left driving roller and the left driven roller;

[0043]The right conveying mechanism is located on the right side of the center of the rectangular tank body, and the right conveying mechanism includes a right driving roller 5 and a right drive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com