High-efficiency fixed-ratio mixing production process for coatings

A fixed-ratio mixing and production process technology, which is applied to rosin coatings, coatings, etc., can solve problems such as uneven coating ratios and insufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

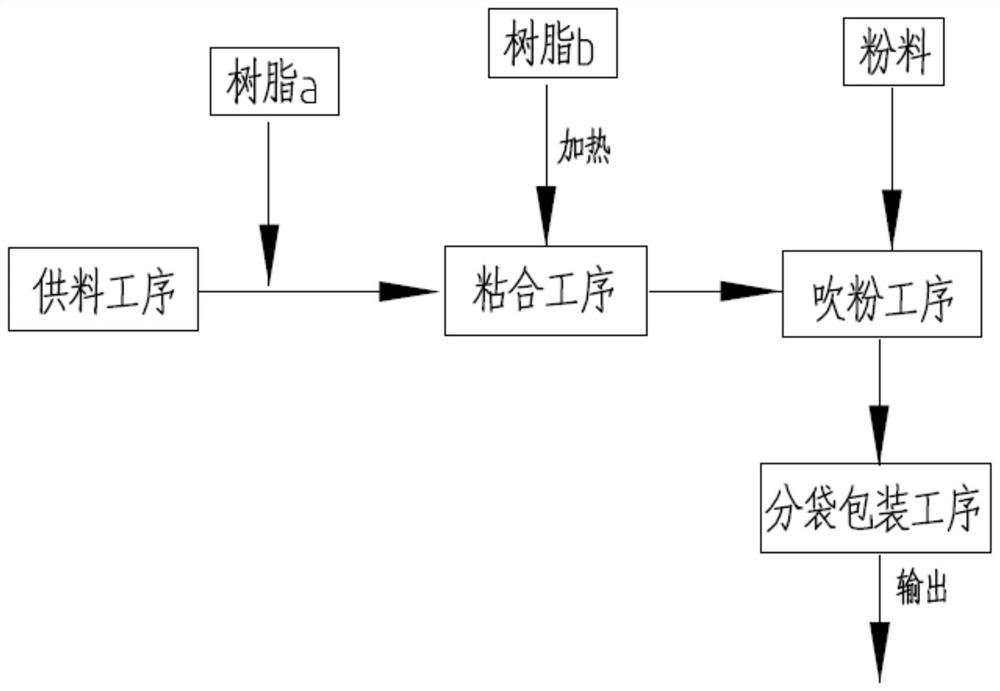

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the high-efficiency fixed-ratio mixing production process for coatings includes the following production steps:

[0057] A. The feeding process, the resin a and resin b that need to be proportioned are sequentially and quantitatively transported to the bonding station through the trough opened on the transfer plate 143, and the powder that needs to be proportioned is transported to the Inside the powder storage device 222 at the powder blowing station;

[0058] B. Bonding process, while transferring the resin a in step A to the bottom of the resin b located at the bonding station, the resin b is heated synchronously, and the resin a and resin b are bonded to form a mixture when they fall synchronously material;

[0059] C. Powder blowing process, during the process of the mixture in step B falling from the bonding station, the powder in the powder sto...

Embodiment 2

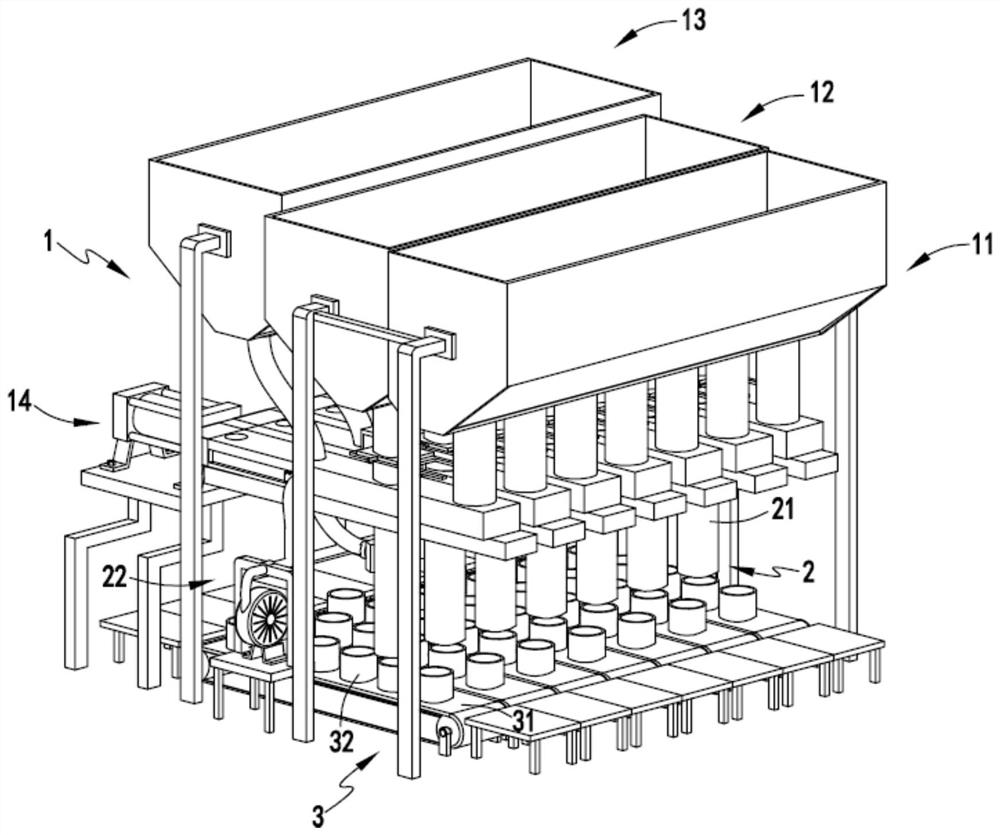

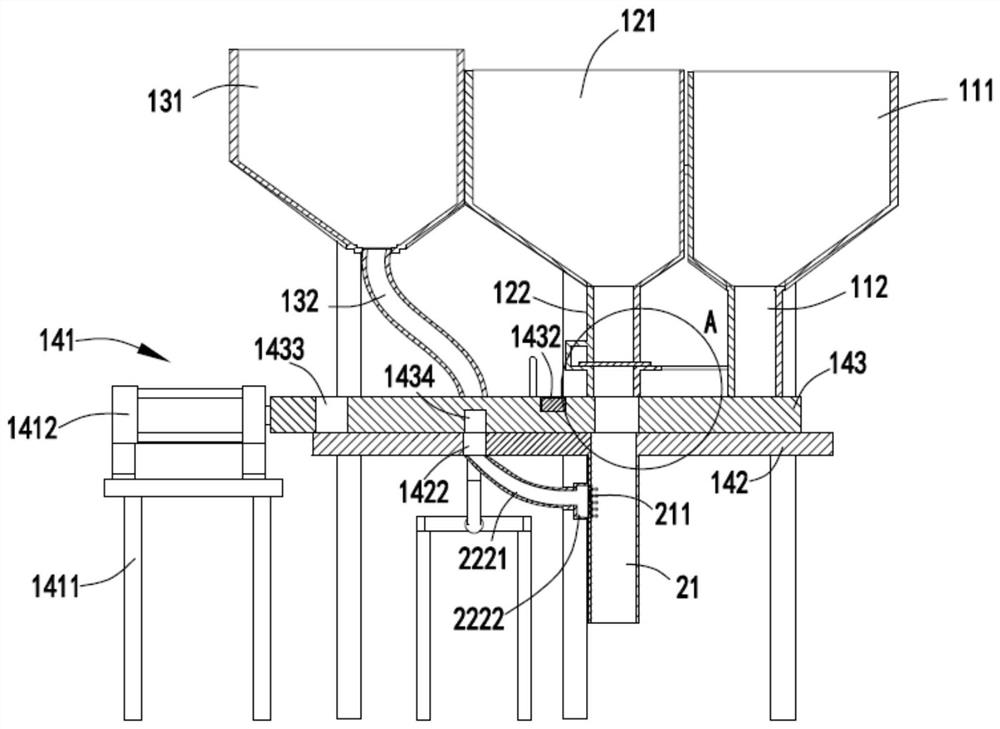

[0071] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the high-efficiency fixed-ratio mixing production system for coatings includes a material supply part 1, and the material supply part 1 includes a feeding device a11 for supplying petroleum resin, a feeding device b12 for supplying modified rosin resin, and a feeding device b12 for supplying modified rosin resin. The feeding device c13 for supplying the powder and the material used to control the feeding device a11, the feeding device b12 and the feeding device c13 are quantitatively transported backwards and the modified rosin resin in the feeding device b12 is carried out during the transportation process. heated transfer mechanism 14;

[0072] Mixing part 2, the mixing part 2 is arranged below the material supply part 1, the mixing part 2 includes a batching tank 21 and a powder blowing mechanism 22 arranged on one side of the batching tank 21, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com