Carbon fiber composite subway vehicle body formed through low cost process

A composite material and carbon fiber technology, used in railway car body, railway car body parts, transportation and packaging, etc., can solve the problems of short service cycle, poor corrosion resistance, high energy consumption, etc., to reduce the number of parts and heat insulation. Excellent performance and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

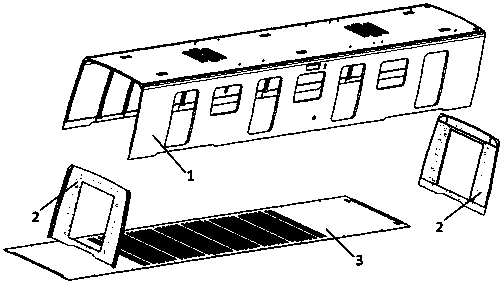

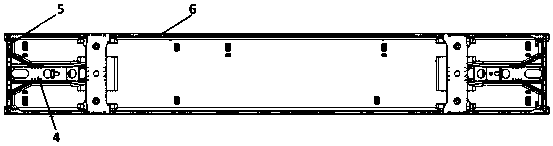

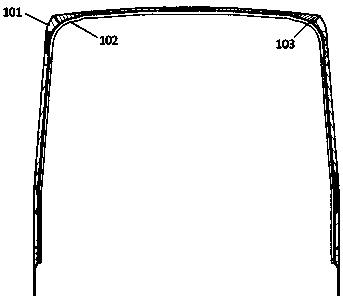

[0037] A carbon fiber composite subway car body formed by a low-cost process, such as figure 1 , including a U-shaped body 1, an end wall 2 and an underframe 3, the U-shaped body 1 is arranged on the underframe 3, the common ends of the U-shaped body 1 and the underframe 3 are respectively provided with an end wall 2, and the U-shaped body 1 adopts Sandwich structure, such as image 3 , the U-shaped body 1 includes an outer skin 101, a sandwich layer 103 and an inner skin 102 arranged sequentially from outside to inside, such as Figure 5 , the end wall 2 adopts a sandwich structure, and the end wall 2 includes an outer skin 201, a sandwich layer 203, and an inner skin 202 arranged sequentially from outside to inside, such as Figure 7 , the underframe 3 adopts a sandwich structure, and the underframe 3 includes an outer skin 301 , a sandwich layer 3 303 and an inner skin 302 arranged sequentially from bottom to top.

[0038] Compared with the existing technology, the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com