Gear and screw connecting type heavy vehicle rear protective device

A rod connection, heavy-duty vehicle technology, applied in vehicle parts, transportation and packaging, vehicle safety arrangements, etc., can solve the problems of large quality of rear guards, unsuitable for promotion, complex structure, etc., and achieves a wide range of applicable models and low power consumption. , the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

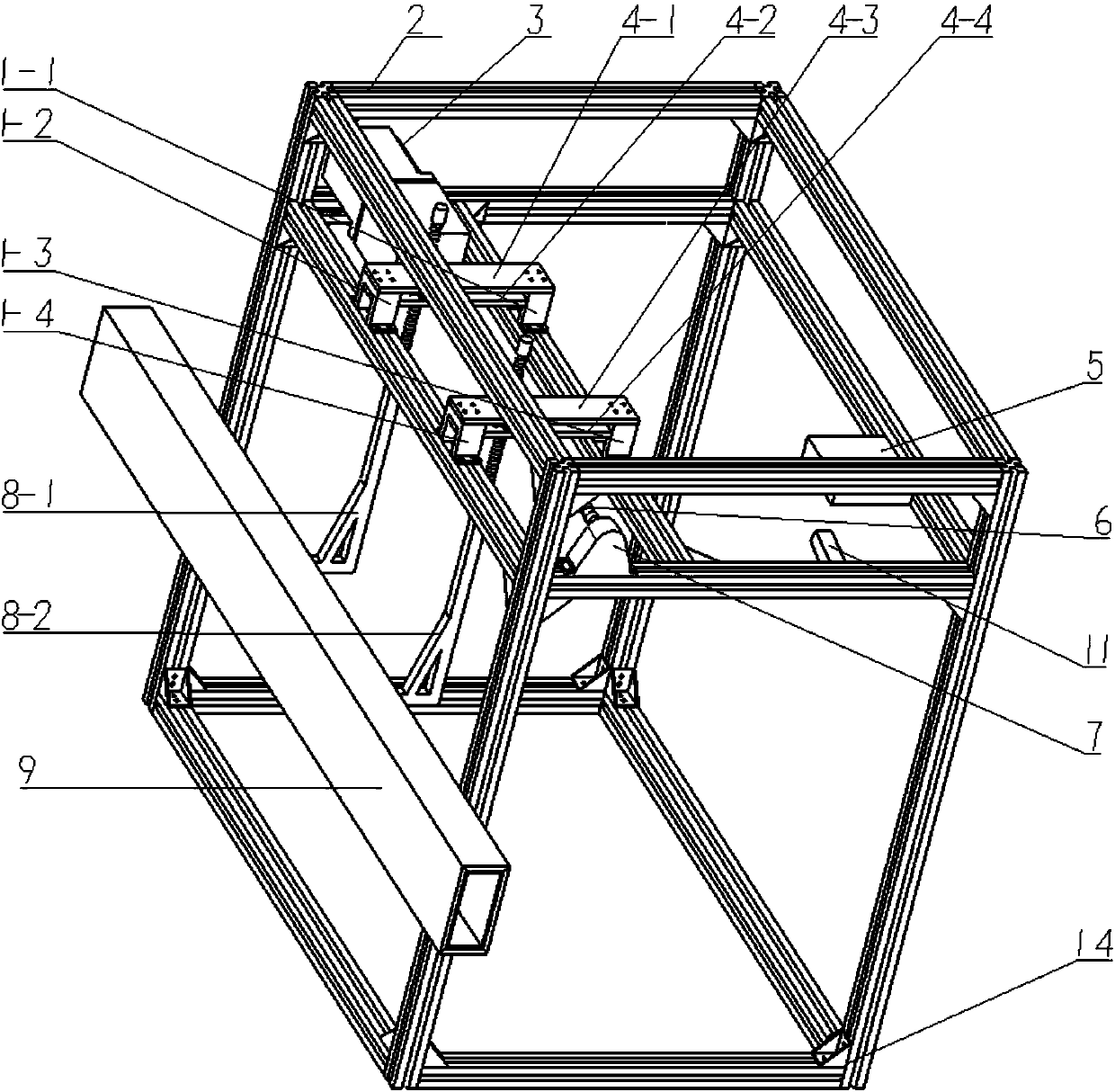

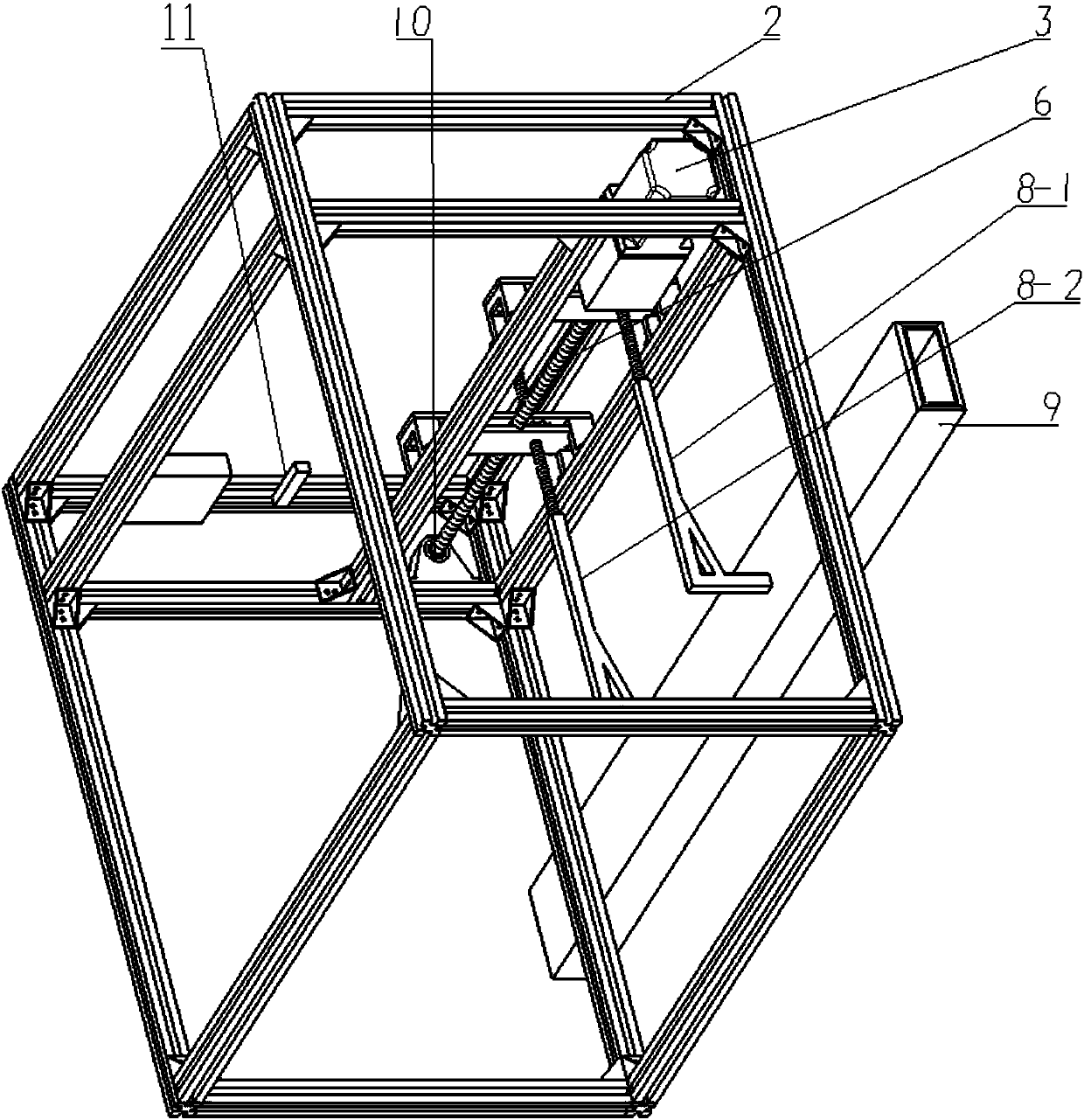

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

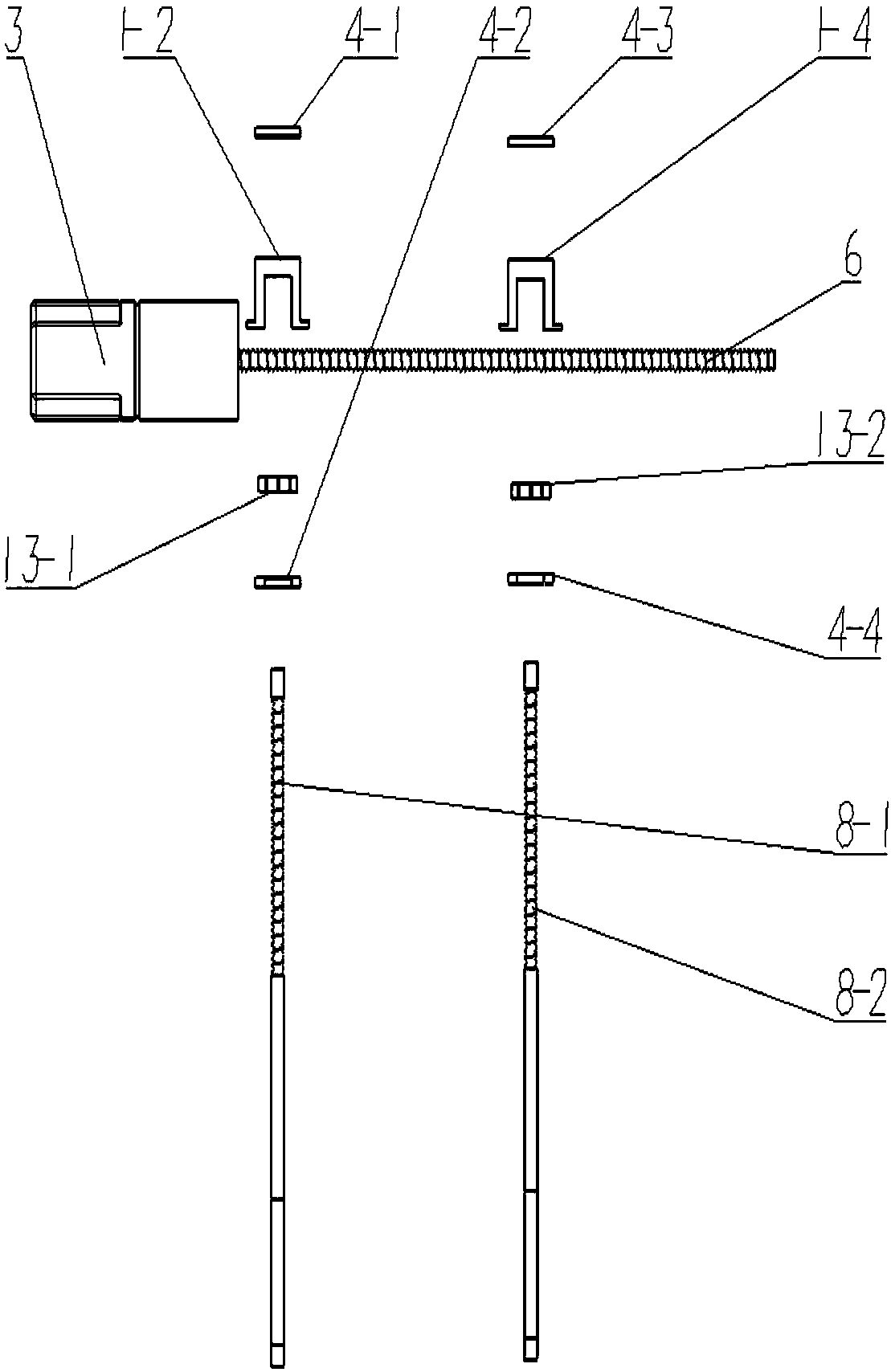

[0037] The gear and screw connection type heavy-duty vehicle rear protection device according to the present invention includes a helical gear fixing frame, a stand 2, a driving motor 3, a controller 5, a screw rod 6, a bearing support 7, a support rod and a bumper 9;

[0038] The helical gear holder includes a No. 1 helical gear holder and a No. 2 helical gear holder, and the No. 1 helical gear holder and the No. 2 helical gear holder have the same structure. The No. 1 helical gear fixing frame includes No. 1 helical gear upper fixing plate 4-1, No. 1 helical gear lower fixing plate 4-2, No. 1 helical gear assembly 13-1, No. 1 helical gear bracket 1-1 and No. 2 Helical gear bracket 1-2; No. 2 helical gear fixed frame includes No. 2 helical gear upper fixing plate 4-3, No. 2 helical gear lower fixing plate 4-4, No. 2 helical gear assembly 13-2, No. 3 helical gear Support 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com