Preparation of liquid metal composite polymer brush motor and its application as a nanomotor

A composite polymer and liquid metal technology, applied in the field of polymer brush motor preparation, can solve problems such as difficult liquid metal compounding, difficult to accurately control the chemical composition and geometric shape of the motor, and difficult to treat waste liquid by electrochemical deposition. The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

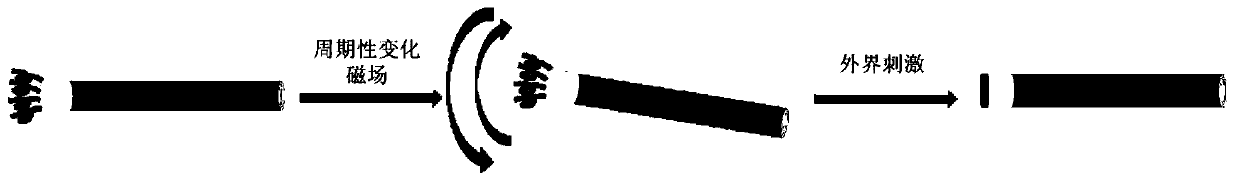

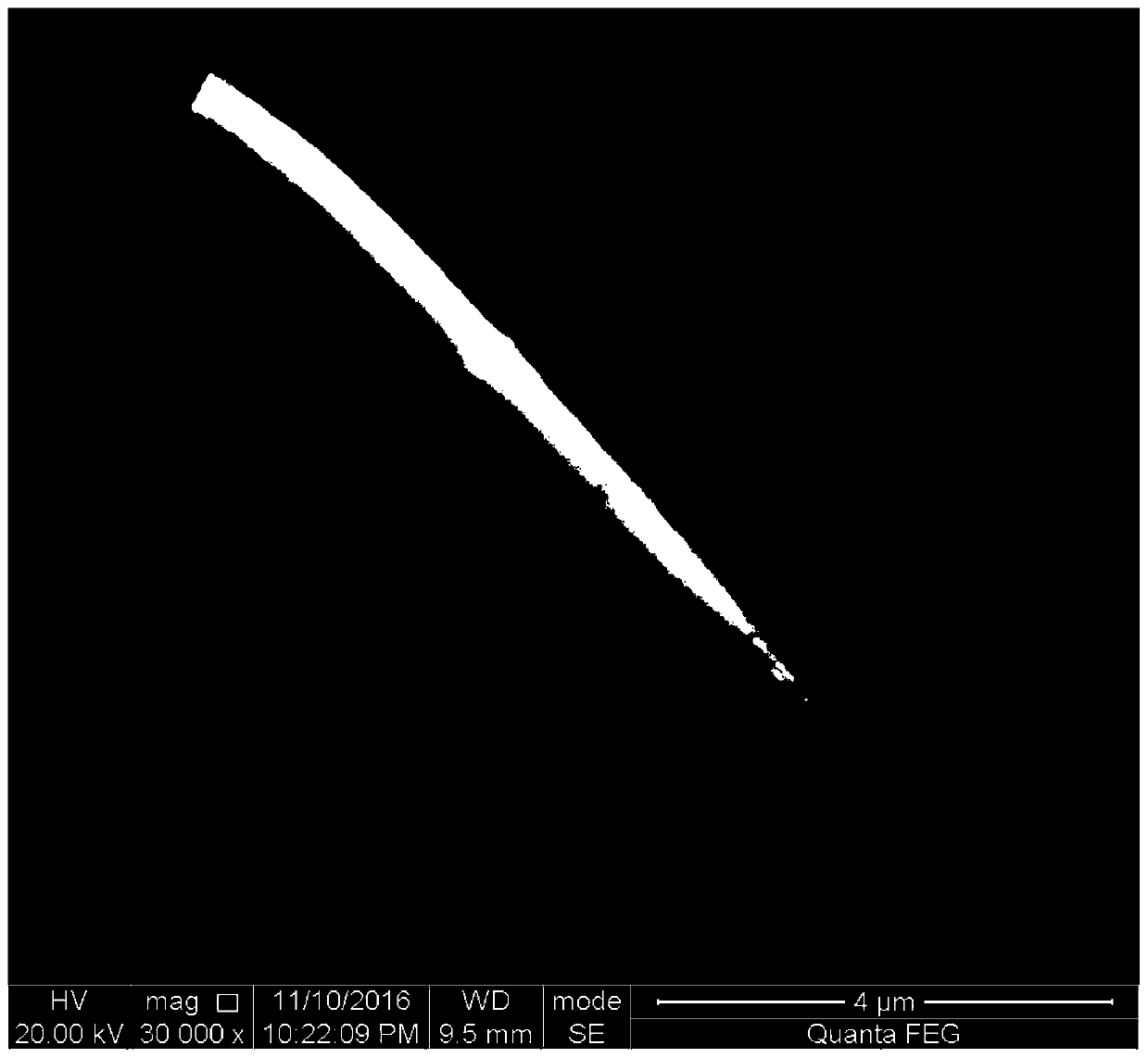

[0021] A method for preparing a liquid metal composite polymer brush motor involved in this embodiment, the steps are as follows,

[0022] Step 1. Weigh 0.1g~2.0g of ferrous chloride and 0.2g~2.5g of ferric chloride in 40ml~100ml of deionized water to make a solution, add the solution into a flask and heat to 65°C~85°C, add 1ml ~ 10ml of ammonia water, continue to heat for 20min ~ 60min after adding, the product is attracted by a magnet and washed 6 ~ 10 times, then add a stabilizer, the stabilizer is sodium citrate, 4ml of sodium citrate with a concentration of 0.1 ~ 1g / ml is stirred After adding, continue to heat for 40min to 200min to obtain magnetic nanoparticles;

[0023] Step 2. Assembly of magnetic nanoparticles: using porous anodized aluminum, polycarbonate (PC) or porous silicon wafer as a template, dilute the concentration of magnetic nanoparticles obtained in step 1 to 0.1-5mg / mL; put the corresponding template into In the diluted magnetic nanoparticle solution, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com