Machine-made sand production technique and production system used for implementing production technique

A production process and machine-made sand technology, applied in grain processing, etc., can solve the problems of heavy screening machine load and easy clogging of the screen, and achieve the effect of avoiding clogging of the screen and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

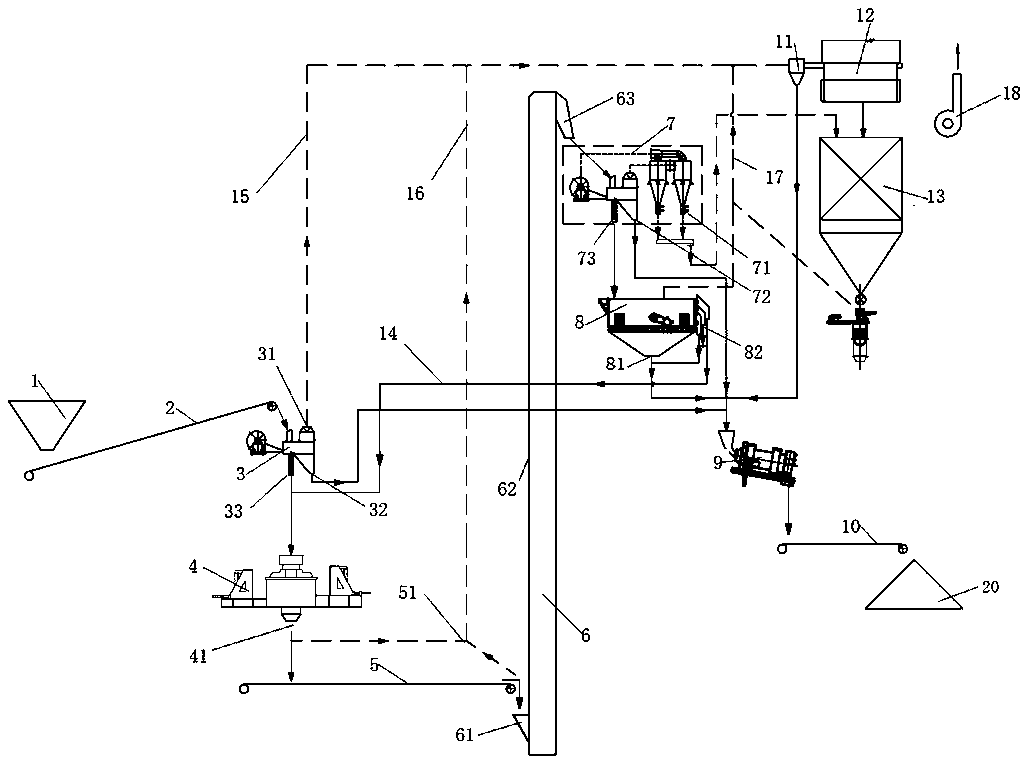

[0035] The production system provided by this embodiment can be used to implement the above-mentioned machine-made sand production process, and the structure of the production system is as follows: figure 1 As shown, it includes a sand making machine 4 and a screening machine 8, and a powder selection and classification system 7 for sorting the materials to be sorted outputted by the sand making machine 4 is arranged between the sand making machine 4 and the screening machine 8. The classifying system 7 has an inlet for materials to be sorted, an outlet for stone powder 71 and an outlet for mixed materials to be screened 73 connected to the inlet of the screening machine 8 .

[0036] In the above machine-made sand production system, the raw materials are stored in the transition silo 1, and the outlet of the transition silo 1 is connected to the inlet of the first belt conveyor 2 below, and the first belt conveyor 2 can transport the raw materials In the powder classifier 3 fo...

specific Embodiment 2

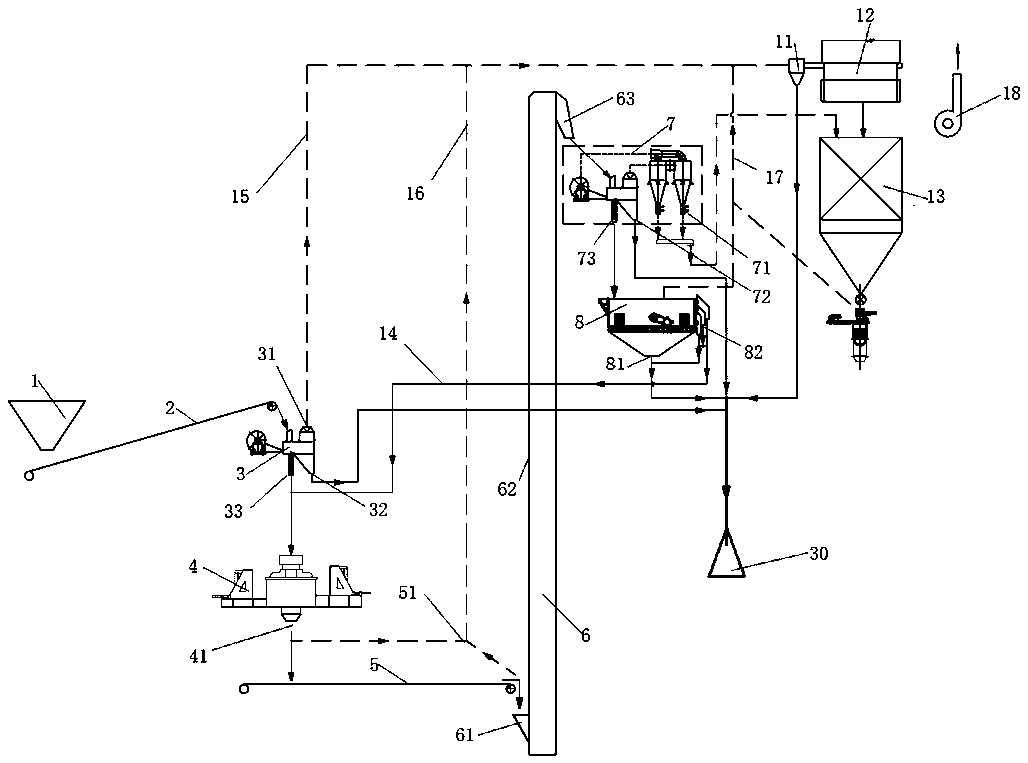

[0058] Such as figure 2 As shown, the machine-made sand production system in this embodiment includes a dry-mixed mortar station, and does not include a wet mixer compared with Example 1, and the finished machine-made sand material directly enters the dry-mixed mortar station 30 without mixing wet, and other structures are the same as It is the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com