Connection arrangement for an electrically conductive contact and a method for producing such a connection arrangement

一种连接组件、导电接触的技术,应用在连接组件领域,能够解决陶瓷破碎、机械强度影响、玻璃碎裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

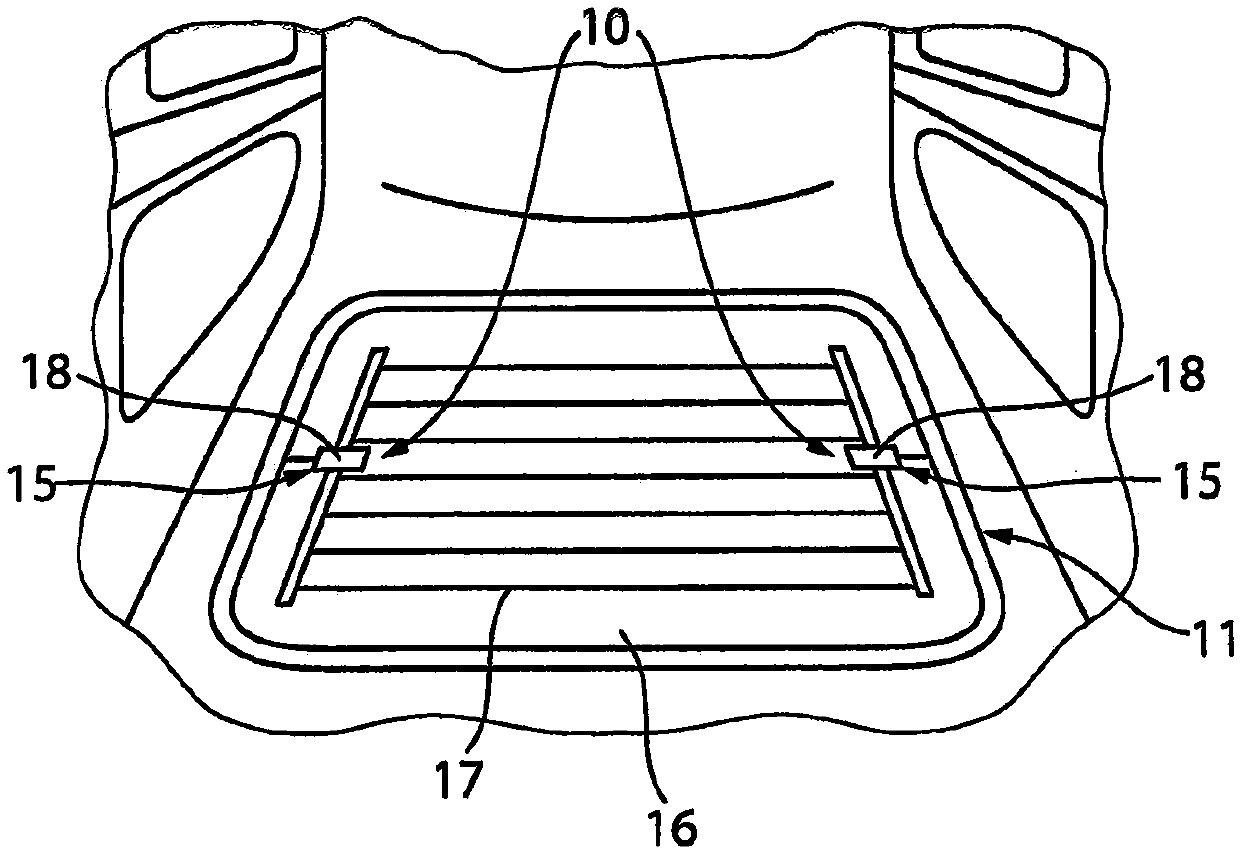

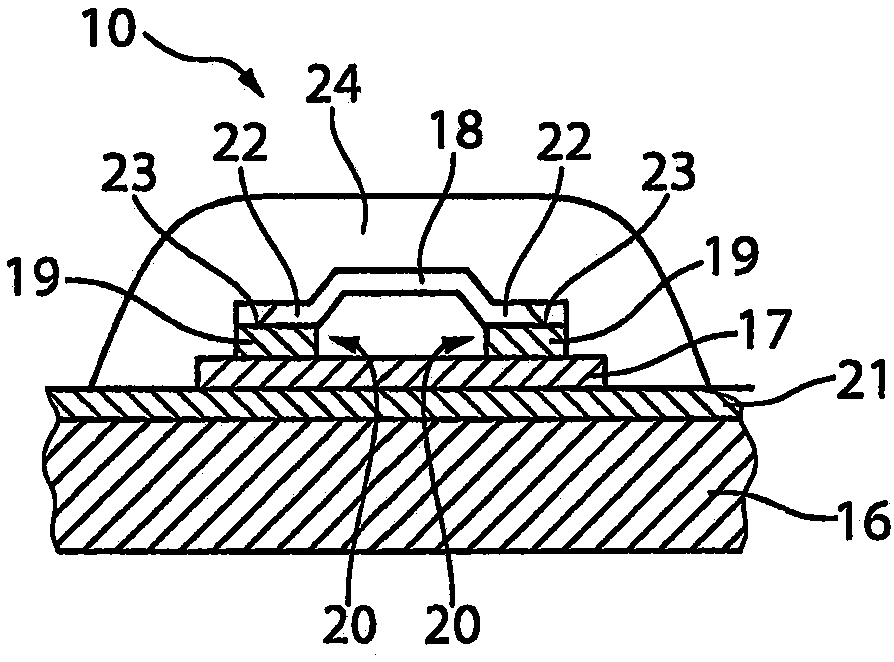

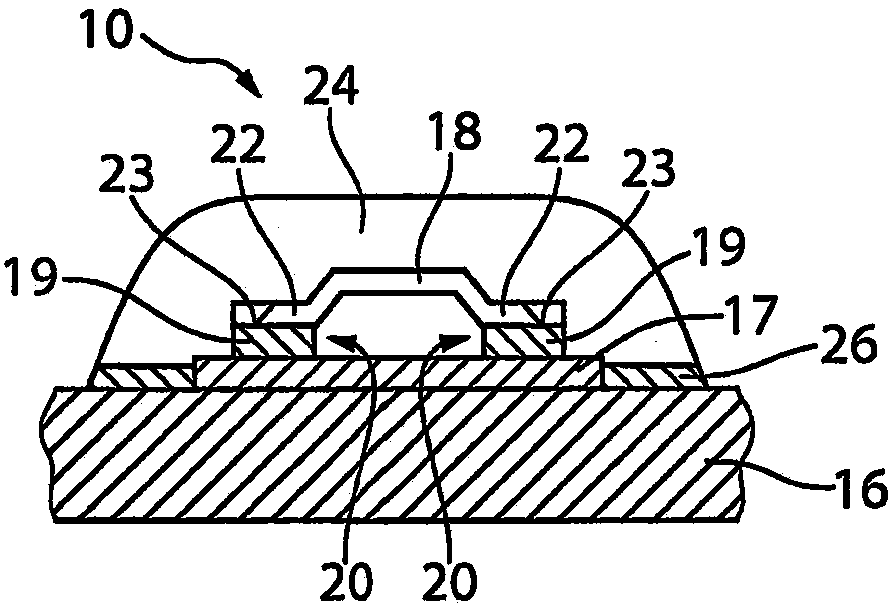

[0020] figure 1 A perspective view of a window pane unit 11 of a motor vehicle is shown. By way of example, the window pane unit 11 is designed as a rear window of the motor vehicle. Likewise, the window pane unit 11 can also be designed as a front window, a side window or as a window for closing a roof opening of a motor vehicle. The pane unit 11 is in particular provided as a fixed pane unit. Likewise, the glazing unit may be openable. The glazing unit 11 includes a glazing 16 . The pane 16 is preferably constructed from single-pane safety glass (ESG) or from laminated safety glass (VSG). Furthermore, a ceramic coating 21 and / or a primer or adhesive 26 can be applied to the window pane 16 .

[0021] The pane 16 has electrical conductors 17 . The electrical conductor 17 can form, for example, a pane heating device for heating the pane 16 . Likewise, the electrical conductor 17 can be provided as an anti-theft device or as an antenna for a car radio, car TV, GPS or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com