Method of analyzing and evaluating stress of high-pressure gas dual-wall tube and elastic support thermal expansion displacement

An elastic support, analysis and evaluation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of lack of analysis and evaluation methods, and achieve the effect of reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

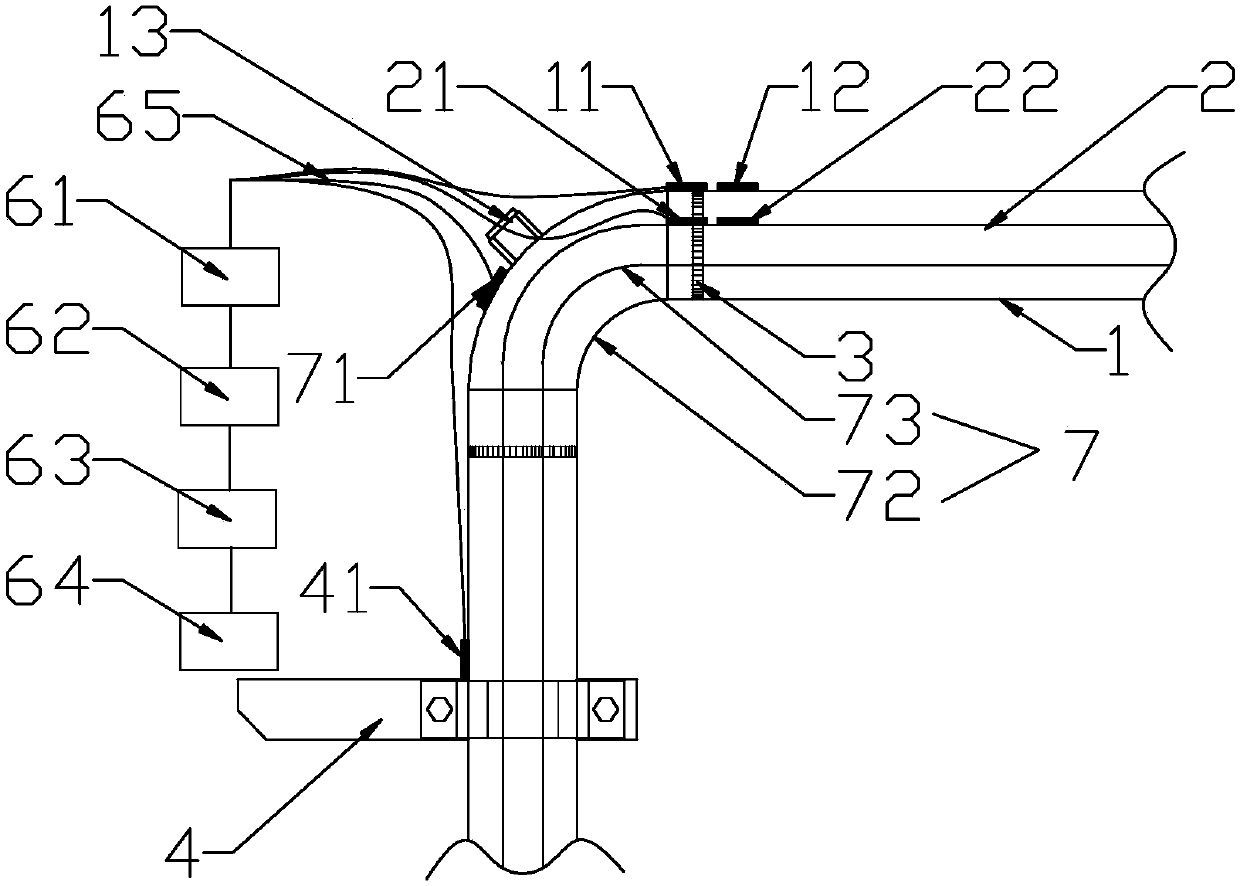

[0059] The strain test system includes an outer tube strain gauge 11 arranged on the outer tube 1, an outer tube displacement sensor 12 and a fixed support strain gauge 41, an inner tube strain gauge 21 and an inner tube displacement sensor 22 arranged on the inner tube 2, and a double Elbow strain gauge 71, signal conditioner 61, static strain gauge 62, data analysis system 63 and computer 64 on wall pipe elbow 7, described outer pipe strain gauge 11, outer pipe displacement sensor 12, fixed bracket strain gauge 41 , the inner pipe strain gauge 21, the inner pipe displacement sensor 22 and the elbow strain gauge 71 are respectively connected with the signal conditioner 61 through the cable 65, and the signal conditioner 61 is connected with the static strain gauge 62, and the static strain gauge 62 It is connected with the data analysis system 63 , and the data analysis system 63 is connected with the computer 64 . Wherein the outer pipe strain gauge 11, the inner pipe strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com