Force touch module, preparation method thereof, touch screen panel and display device

A touch module and module technology, applied in the fields of touch screens and display devices, preparation methods, and pressure-sensitive touch modules, can solve problems such as lower yield rate, lower product yield rate, and complex structure of display devices, and achieve the goal of ensuring lightness and thinness The effect of optimizing and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Reference Figure 4 As shown, a flow chart of an embodiment of a manufacturing method of a pressure-sensitive touch module provided in this application, the manufacturing method includes:

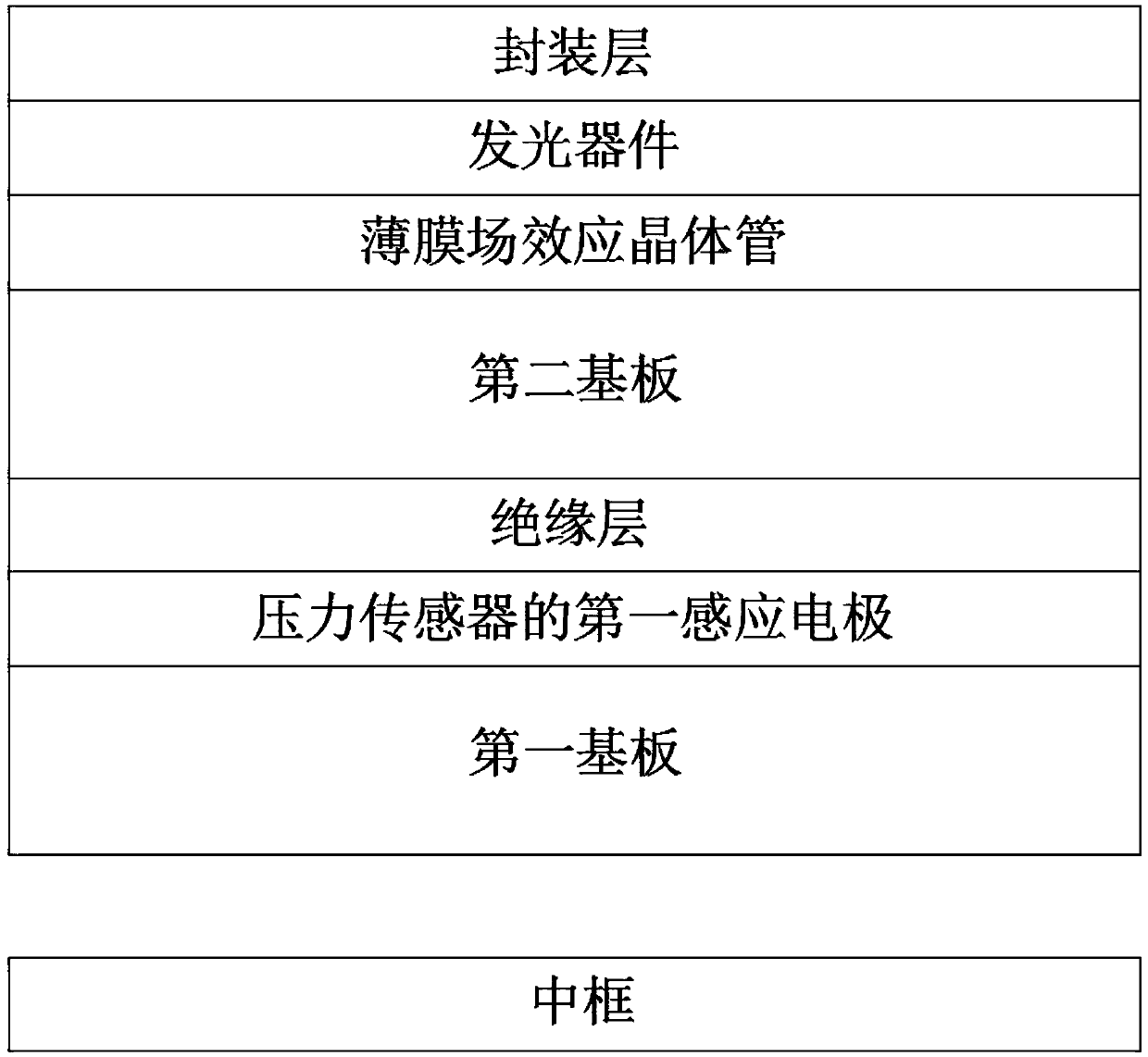

[0044] Preparing a first substrate, and laying electrode material on the first substrate as the first sensing electrode of the pressure sensor;

[0045] Preparing an insulating layer on the first sensing electrode;

[0046] Preparing a second substrate on the insulating layer;

[0047] Forming a via hole on the second substrate at a position corresponding to the first sensing electrode, and making the via hole pass through the insulating layer;

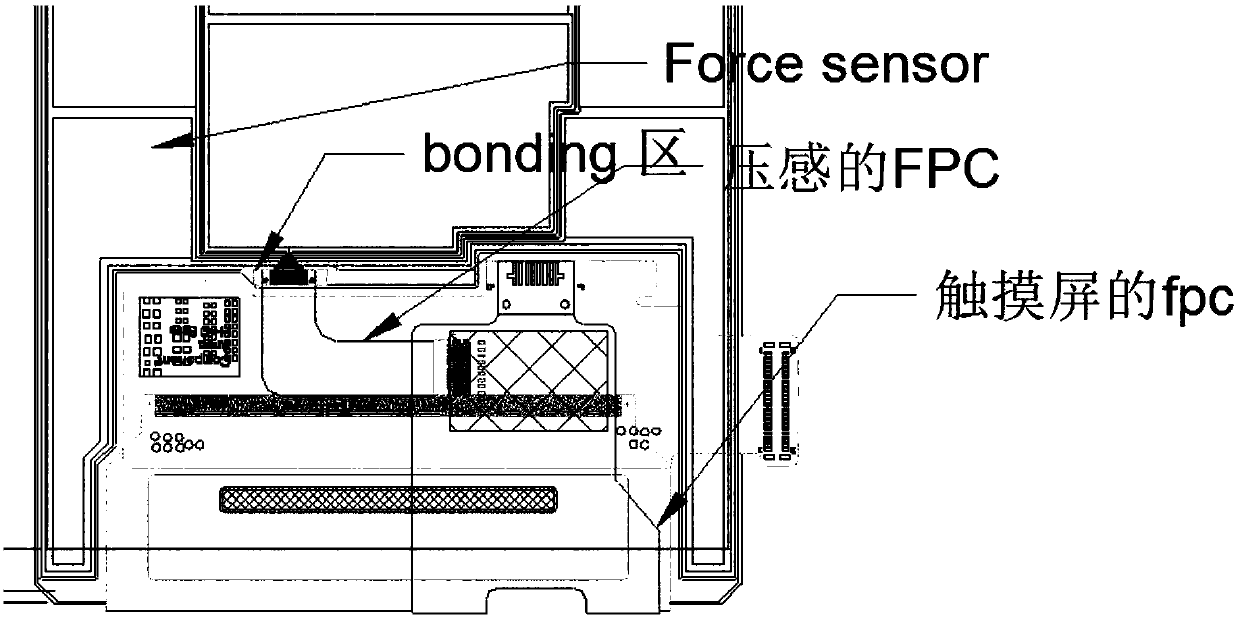

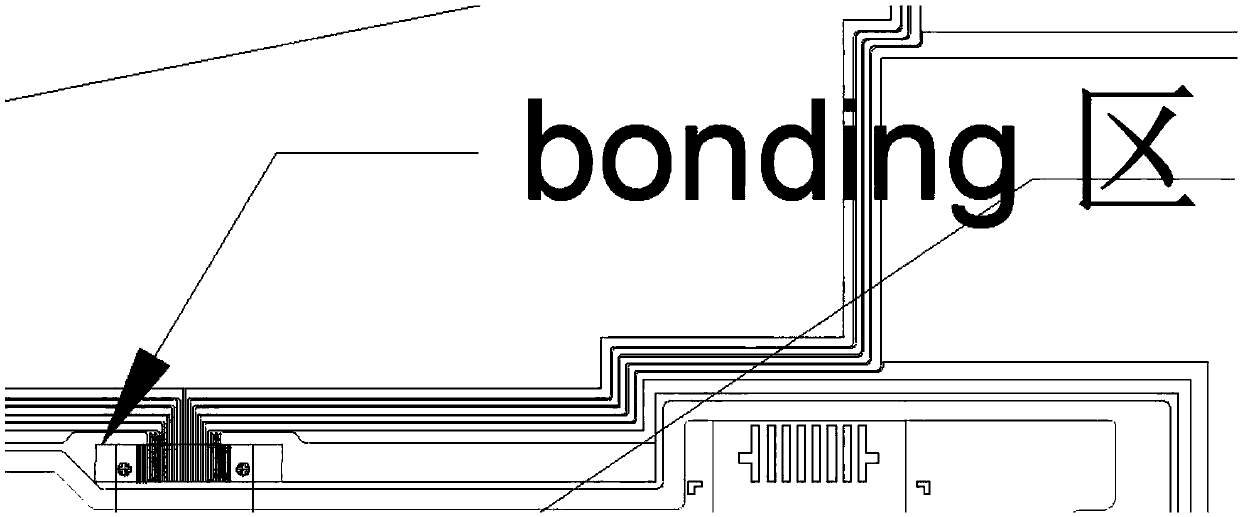

[0048] A pressure-sensitive signal line is prepared on the second substrate, and one end of the pressure-sensitive signal line is connected to the first sensing electrode through a via hole, and the other end is connected to a flexible circuit corresponding to the device.

[0049] The subsequent preparation of the remaining layer structure is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com