Compressor, compressor parallel system and multi-online heat exchange system

A compressor and parallel connection technology, which is applied in the field of compressors, can solve problems such as easy wear and noise of the crankshaft, and achieve the effects of improving high-frequency energy efficiency, prolonging service life, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

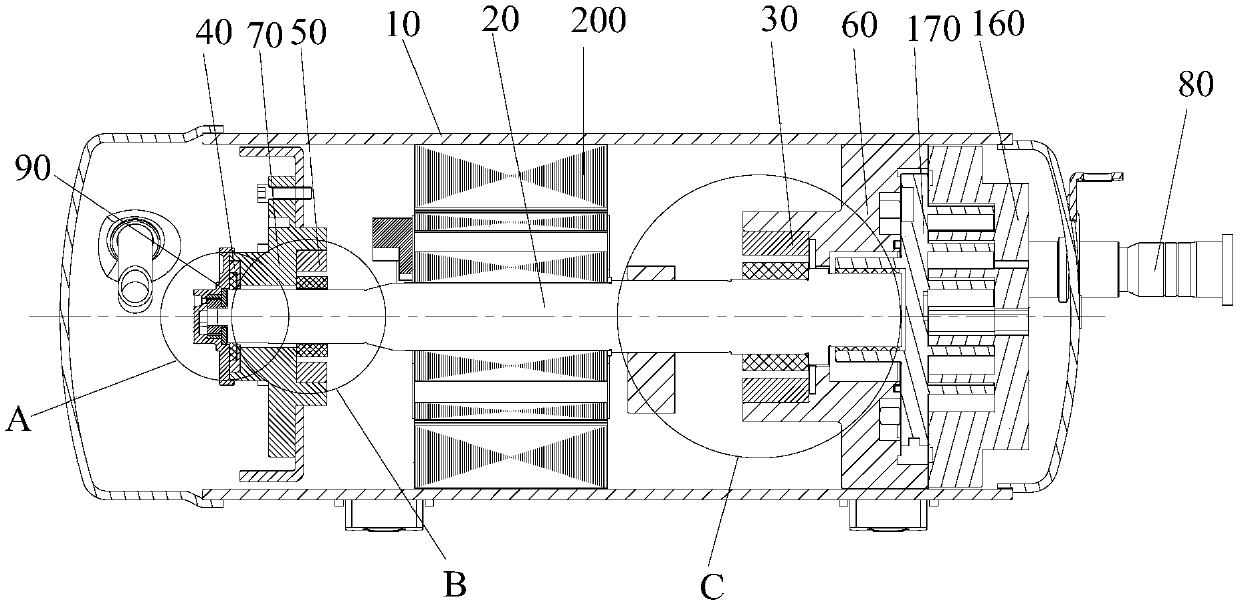

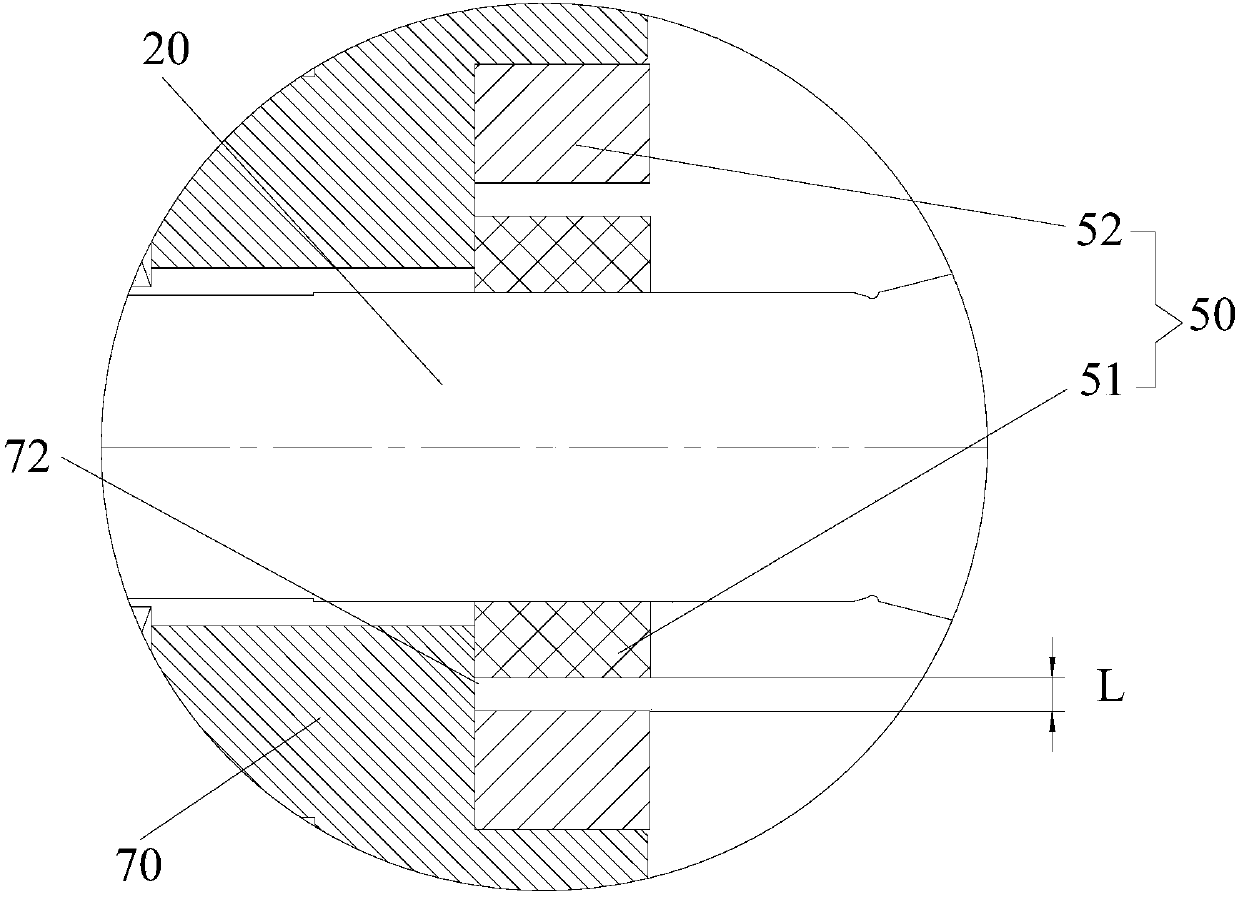

[0034] Such as figure 1 As shown, the compressor of the first embodiment includes a casing 10 and a crankshaft 20 disposed in the casing 10 , and the compressor also includes a first magnetic suspension bearing 30 and a second magnetic suspension bearing 40 . Wherein, the first magnetic suspension bearing 30 is arranged in the casing 10 . The second magnetic suspension bearing 40 is arranged in the housing 10 , and the first magnetic suspension bearing 30 and the second magnetic suspension bearing 40 are respectively arranged at two ends of the crankshaft 20 .

[0035] During the operation of the compressor, the first magnetic suspension bearing 30 and the second magnetic suspension bearing 40 play the role of supporting and positioning the crankshaft 20, preventing the crankshaft 20 from moving in the radial and axial directions relative to the housing 10 during the rotation process. . In this way, the first magnetic suspension bearing 30 and the second magnetic suspension ...

Embodiment 2

[0055] The difference between the compressor of the second embodiment and the first embodiment lies in that the structure of the compressor is different.

[0056] Such as Figure 5 As shown, in this embodiment, the compressor further includes a bearing structure 100 . Wherein, the bearing structure 100 is arranged on the crankshaft 20 , and the bearing structure 100 is located between the first magnetic suspension bearing 30 and the second magnetic suspension bearing 40 . In this way, during the normal operation of the compressor, the first magnetic suspension bearing 30 and the bearing structure 100 play a role in radially positioning the crankshaft 20, and the second magnetic suspension bearing 40 plays a role in positioning the crankshaft 20 in the axial direction, thereby ensuring that the crankshaft 20 is There is no displacement or play in the radial and axial directions during the rotation.

[0057] From the above description, it can be seen that the above-mentioned e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com