Combined type wooden door

A combined, wooden door technology, applied in the direction of door leaf, window/door, window/door frame, etc., can solve the problems of troublesome disassembly and assembly of door frame, low structural strength, insufficient structural strength, etc. Simple installation and the effect of increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

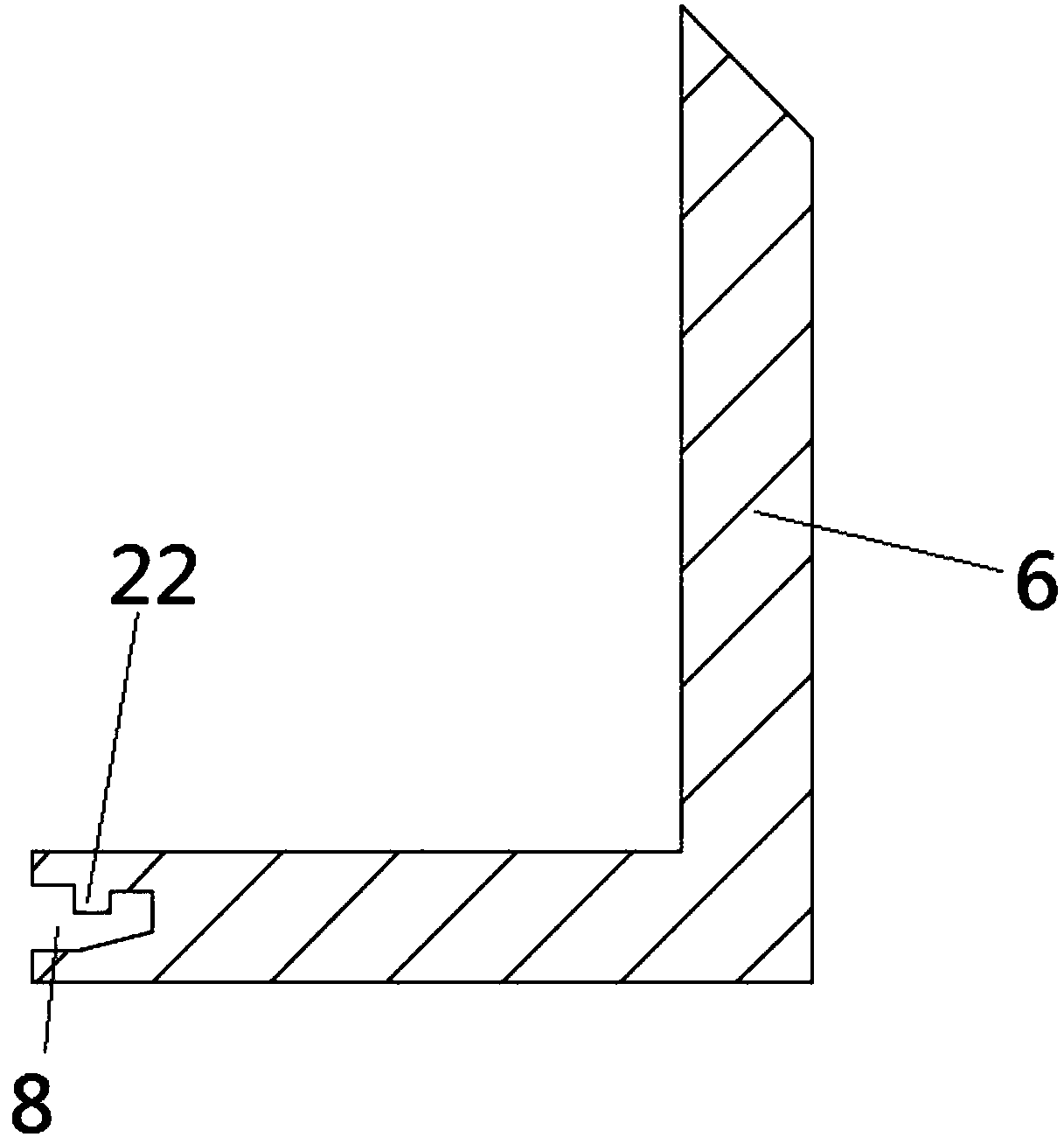

[0024] Example: A combined wooden door with a structure such as Figure 1 to 8 As shown, it includes a door frame portion 1, which is hinged with a door leaf portion 3 via a hinge 2; the door frame portion 1 includes a pair of first connecting portions 4 arranged symmetrically up and down, with positioning blocks 5 between the first connecting portions 4 The first connecting portion 4 is mortise-connected with a second connecting portion 6, and the second connecting portions 6 are connected by a positioning block 5. The first connecting portion 4 is provided with a tenon 7, and the second connecting portion 6 is provided with The groove 8 is matched with the tenon 7; the door leaf portion 3 includes a three-layer solid wood structure, in which there are thin wood layers 9 on both sides, and an assembling layer 10 is sandwiched between the thin wood layers 9; the assembling layer 10 includes a For the symmetrically arranged first C-shaped wood board 11, the lower end of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com