Air filter paper containing carbon nanomaterials and preparation method thereof

A technology of air filter paper and carbon nanomaterials, applied in the direction of filter paper, separation method, filtration separation, etc., can solve the problems of potential safety hazards, easy to fall off powder, great influence on air filtration effect, etc., achieve small air resistance, excellent antibacterial The effect of performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing air filter paper containing carbon nanomaterials includes the following steps:

[0044] (1) After mixing glass wool fibers with a diameter of 0.1~2μm and glass fibers with a diameter of 6.5μm in a mass ratio of 1:1, add acid to adjust the pH to 3, then disperse and disperse, and send to the former for suction to form Wet paper

[0045] (2) Adding the same mass of carbon nanotubes and alcohol ether glycosides with a diameter of 50-100 nm into water for ultrasonic dispersion, and configuring the carbon nanotube material dispersion with a mass fraction of carbon nanotubes of 0.5%;

[0046] (3) Mix the carbon nano-material dispersion and the polyurethane adhesive at a mass ratio of 1:1, add deionized water to prepare a mixed diluent with the total mass fraction of the carbon nanotube dispersion and the polyurethane adhesive of 1% ;

[0047] (4) Apply the mixed diluent (ie sizing) to the molded wet paper by curtain sizing. The side where the mixed diluent is ...

Embodiment 2

[0050] A preparation method of carbon nano-material-containing air filter paper is basically the same as in Example 1, except that the vacuum degree of the sizing process in step (4) is controlled at 30KPa.

[0051] Such as figure 2 As shown, the thickness of the air filter paper containing carbon nanomaterials obtained in this embodiment is 350 μm, and the carbon nanotubes are uniformly distributed throughout the air filter paper containing carbon nanomaterials. The air filter paper containing carbon nanomaterials obtained in this embodiment has a removal rate of greater than 99.999% for particles with a particle size greater than 0.3 μm in the air, and a resistance of only 260 Pa. The particle size of the filter paper that is most easily penetrated in the air is 0.05 to 0.3. The removal rate of μm particles is over 99.9%; at the same time, it has good antibacterial performance, and its antibacterial efficiency is greater than 99.9%.

Embodiment 3

[0053] A preparation method of carbon nano-material-containing air filter paper is basically the same as in Example 1, except that the vacuum degree of the sizing process in step (4) is controlled at 50KPa.

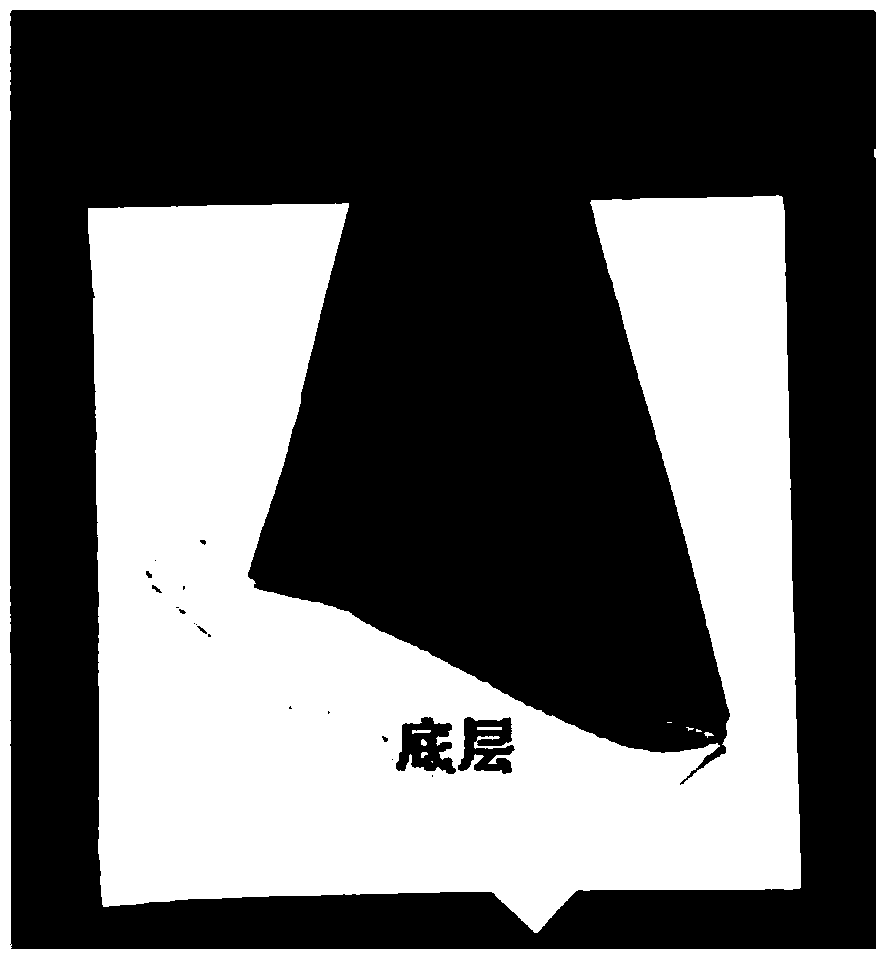

[0054] Such as image 3 As shown, the air filter paper containing carbon nanomaterials obtained in this embodiment has a thickness of 380 μm and has a double-layer structure including a surface layer and a bottom layer. The surface layer is a layer including a sizing surface. The layer is the bottom layer, and the carbon nanotubes are evenly distributed on the bottom layer; the air filter paper containing carbon nanomaterials obtained in this embodiment has a removal rate of more than 99.999% for particles with a particle size greater than 0.3 μm in the air, and the resistance is only 265 Pa. The removal rate of easily penetrating filter paper with a particle size of 0.05-0.3μm is above 99.9%; at the same time, it has good antibacterial performance, and its antibacterial eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com