A corrugation measuring instrument for side-grinding rails on railway curves

A technology for measuring instruments and rails, applied in the engineering field, can solve the problems of accelerated development, defects, undetectable and elimination, etc., and achieve the effect of delaying the regeneration cycle and eliminating surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

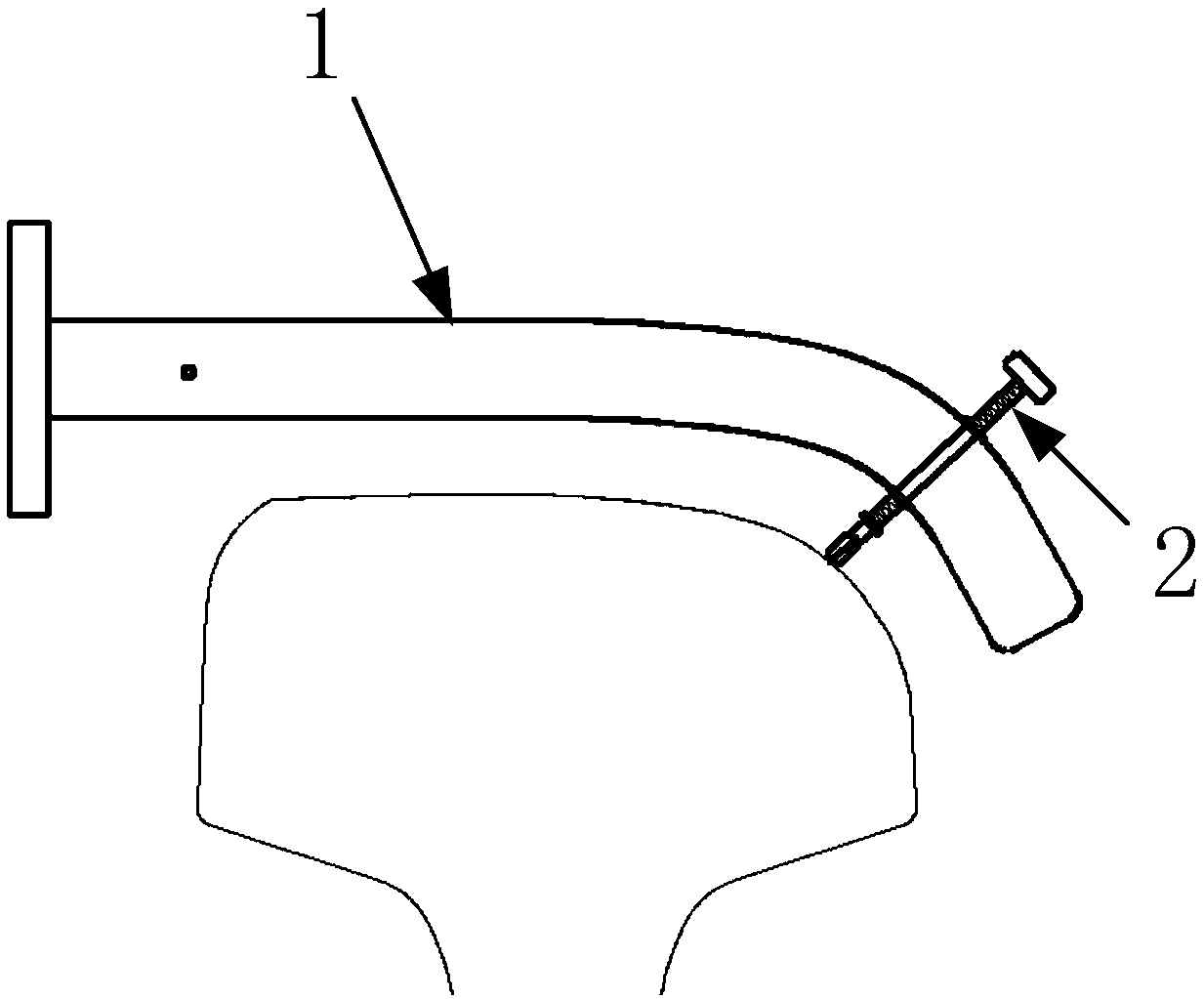

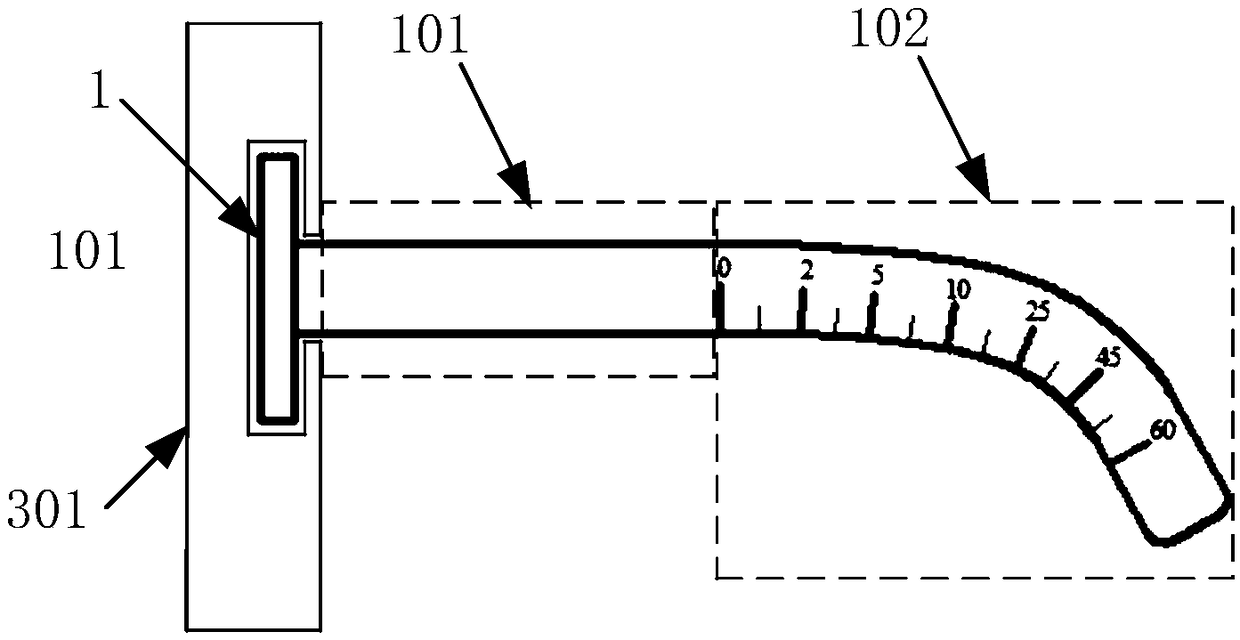

[0025] The rail corrugation measuring instrument of the present invention includes a measuring arm 1 and a displacement probe 2, such as figure 1 Shown; through the support frame 3 erected on the rail rail head.

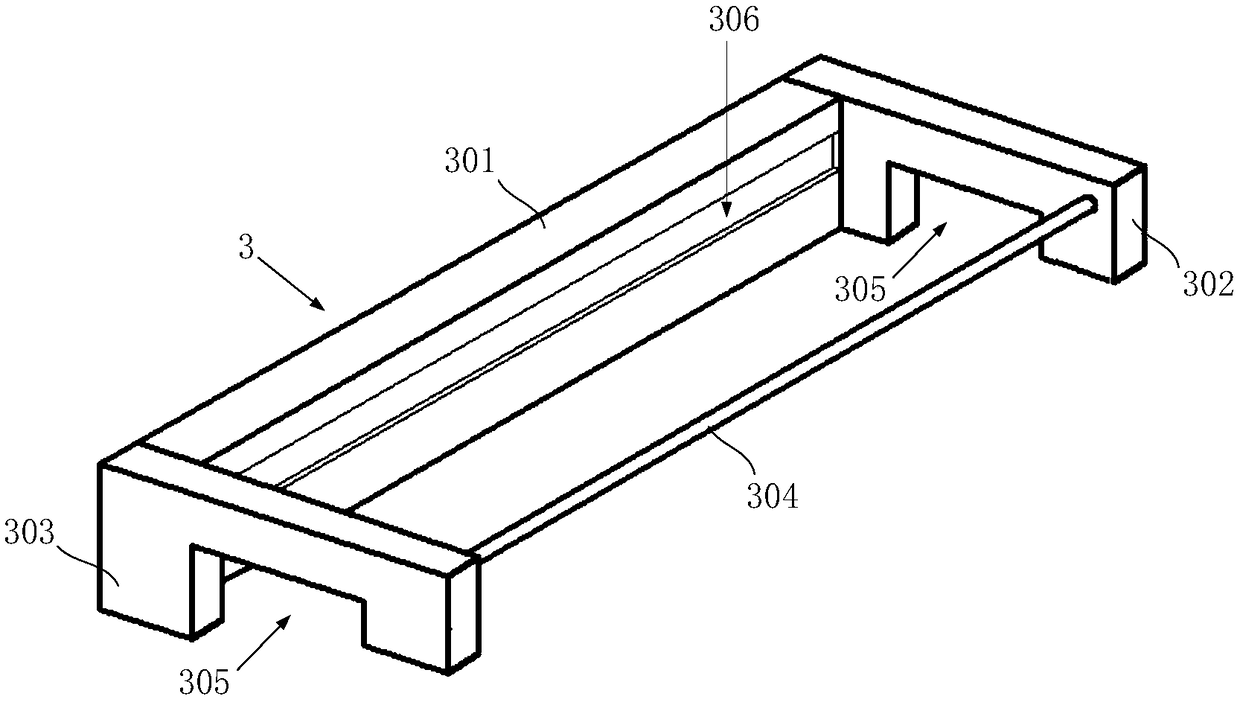

[0026] Described support frame 3 comprises side frame 301, front base 302, rear base 303 and connecting rod 304, as figure 2 shown. Wherein, the front base 302 and the rear base 303 are connected to each other through side frames 301 arranged along the direction of the rail; meanwhile, the front base 302 and the rear base 303 are connected to each other through a connecting rod 304 arranged along the direction of the rail. The connecting rod 304 stabilizes the structure of the supporting frame and facilitates the handling of the measuring instrument. The bottom of the front base 302 and the bottom of the rear base 303 are provided with a slot 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com