Fish tofu cutting device

A fish tofu and cutting technology, which is applied in metal processing and other directions, can solve the problems of large and small pieces of fish tofu, heavy workload, low efficiency, etc., and achieve the effect of simple structure, automatic cutting and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

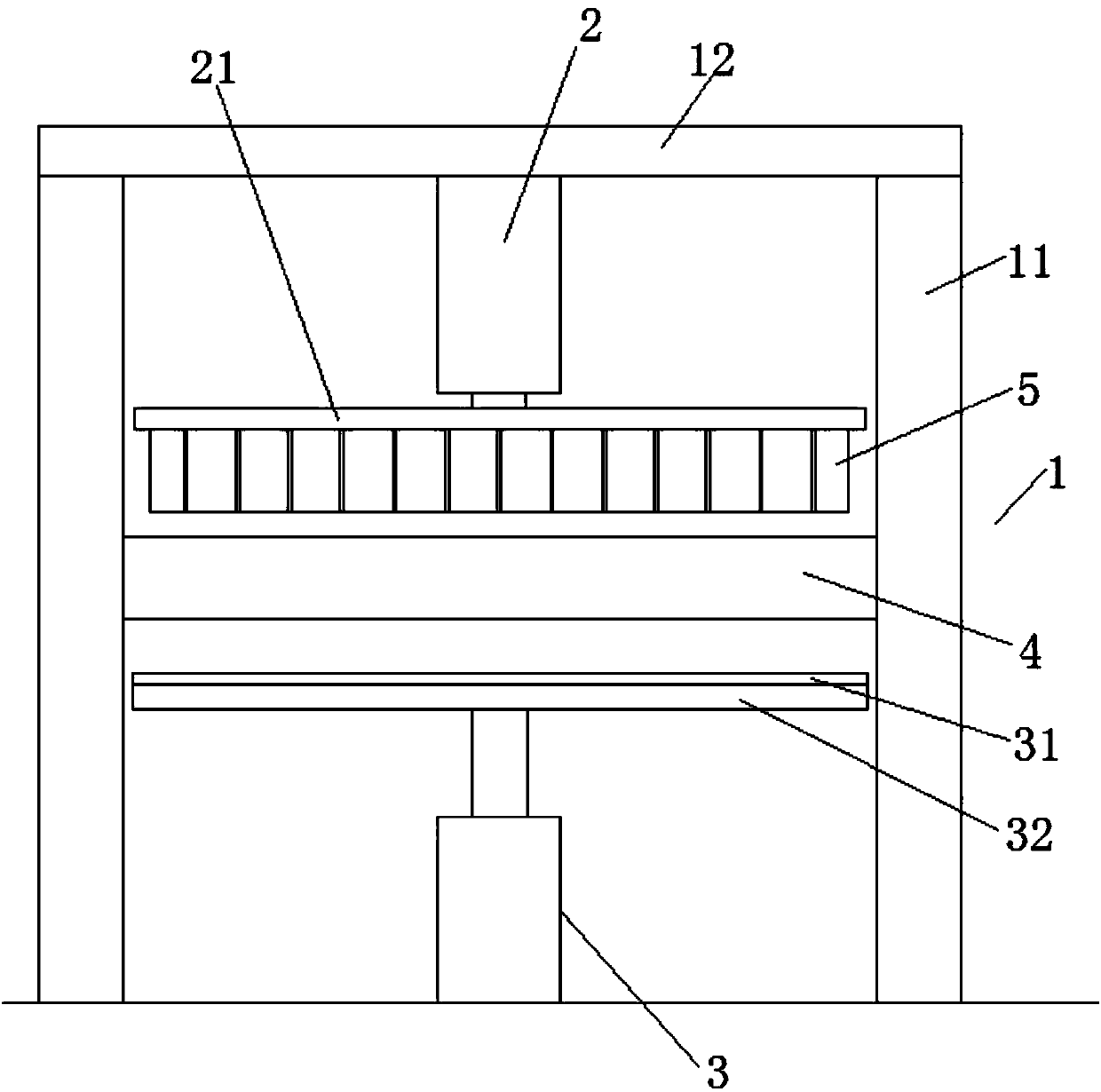

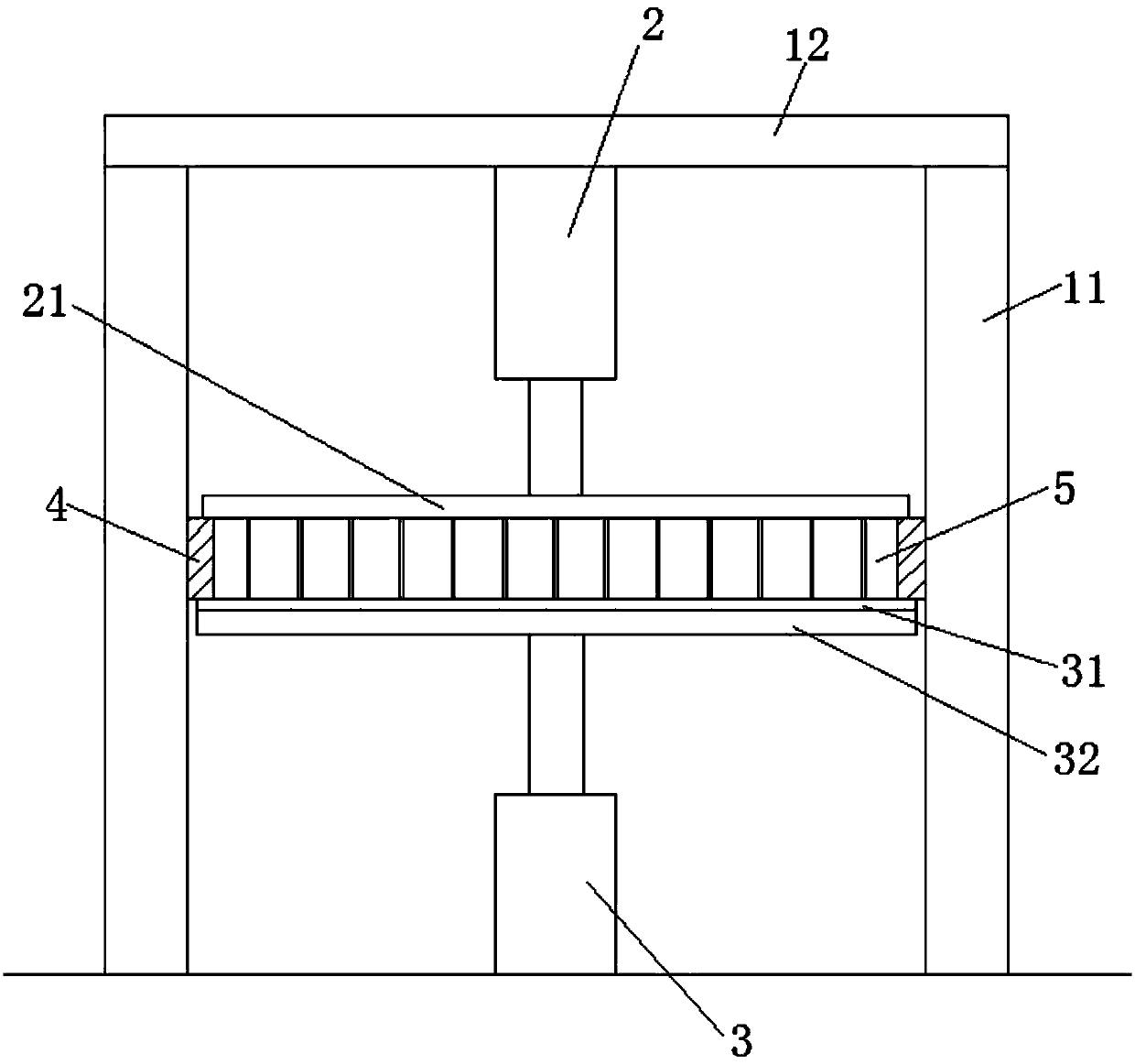

[0036] Example: such as Figures 1 to 4 As shown, the fish tofu cutting device of the present embodiment includes a support 1, an upper cutting mechanism 2, a lower lifting mechanism 3 and a discharge mechanism 6;

[0037] Above-mentioned support 1 is made of four upright columns 11 arranged vertically and distributed in a cuboid shape and a top plate 12 horizontally fixed on the upper ends of four upright columns 11;

[0038] A rectangular cutting frame 4 is horizontally arranged between the middle parts of the four above-mentioned columns 11;

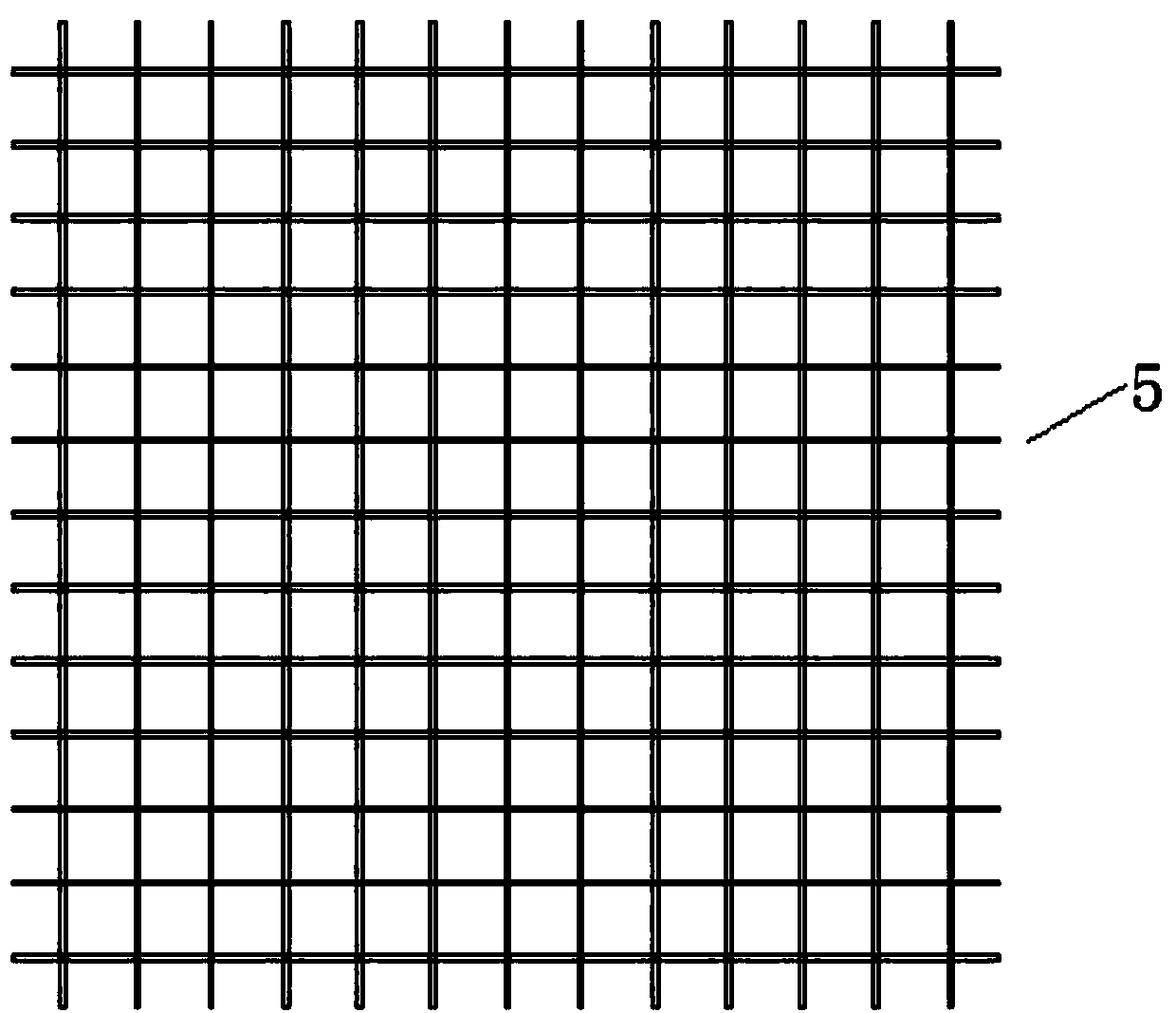

[0039] Above-mentioned upper cutting mechanism 2 comprises being installed in the middle part of the lower end of above-mentioned top board 12, and its driving end is arranged downwards, and is horizontally provided with and matches with above-mentioned cutting frame 4 (specifically, cutting knife 5 stretches into cutting frame 4 Inside, its outer contour is a grid-shaped cutting knife 5 that is in contact with the side wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com