Helical turbulence water cooling reel of metal wire drawer

A metal wire and wire drawing machine technology, applied in the field of mechanical equipment, can solve the problems of reel fouling and cooling effect decline, and achieve the effects of avoiding fouling, reducing temperature rise, and improving cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

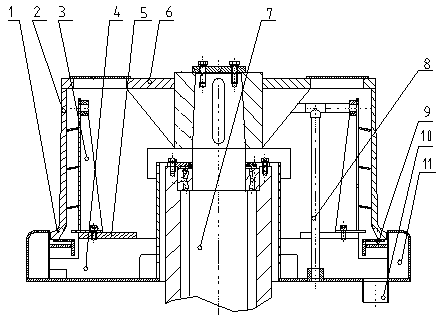

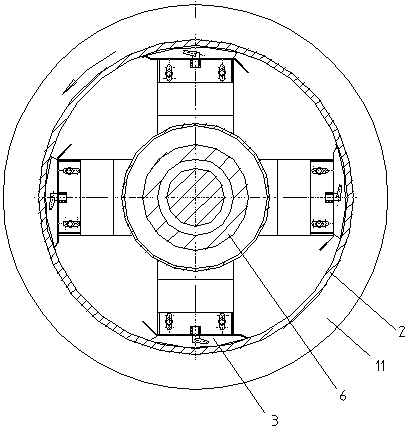

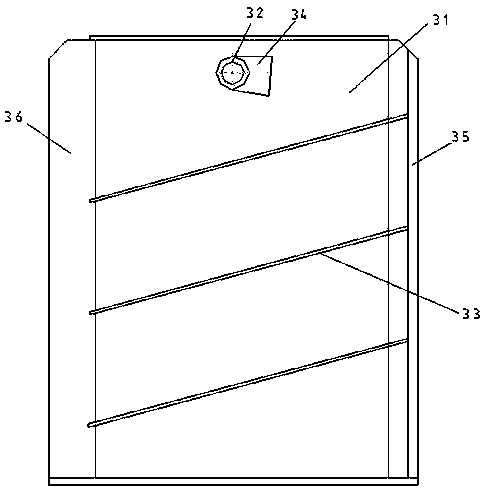

[0025] like Figure 1 to Figure 5 As shown, the present invention includes a hollow reel 2, the hub 6 in the center of the reel 2 is connected to the inner and lower drive shaft 7, the drive shaft 7 is the output shaft of the reducer, in the hollow cavity of the reel 2, facing the inner wall of the reel Four sprinklers 3 are installed, and the sprinklers are evenly spaced at equal intervals on the inner circumference of the reel. N pieces can be actually fitted according to the size of the reel. The sprinklers 3 include a vertical mounting frame 31 and a The sprinkler head 32 and the middle and lower parts of the mounting frame are provided with a downwardly inclined water guide plate 33. The nozzle 34 of the sprinkler head is inclined in the direction of the upper end of the water guide plate 33. , the bottom of the surrounding wall of the reel 2 is the R part 1 that is bent outward, and the R part 1 is placed on the baffle plate 9 in the water tank around the water receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com