Production technology of silver-loaded resin adsorbent for acetic acid deiodination

A resin adsorption and production process technology, applied in the direction of selective adsorption, silver compounds, silver compounds, etc., can solve the problems of secondary pollution and weak adsorption, and achieve the effect of improving adsorption capacity, high deiodination efficiency, and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

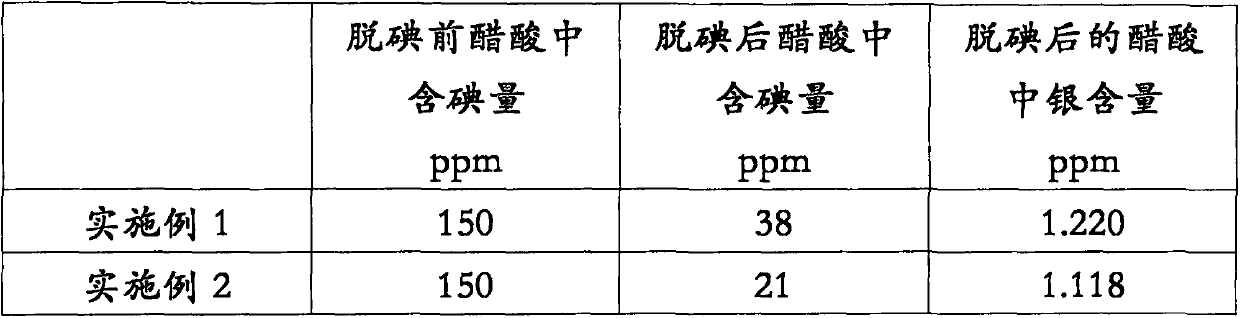

Embodiment 1

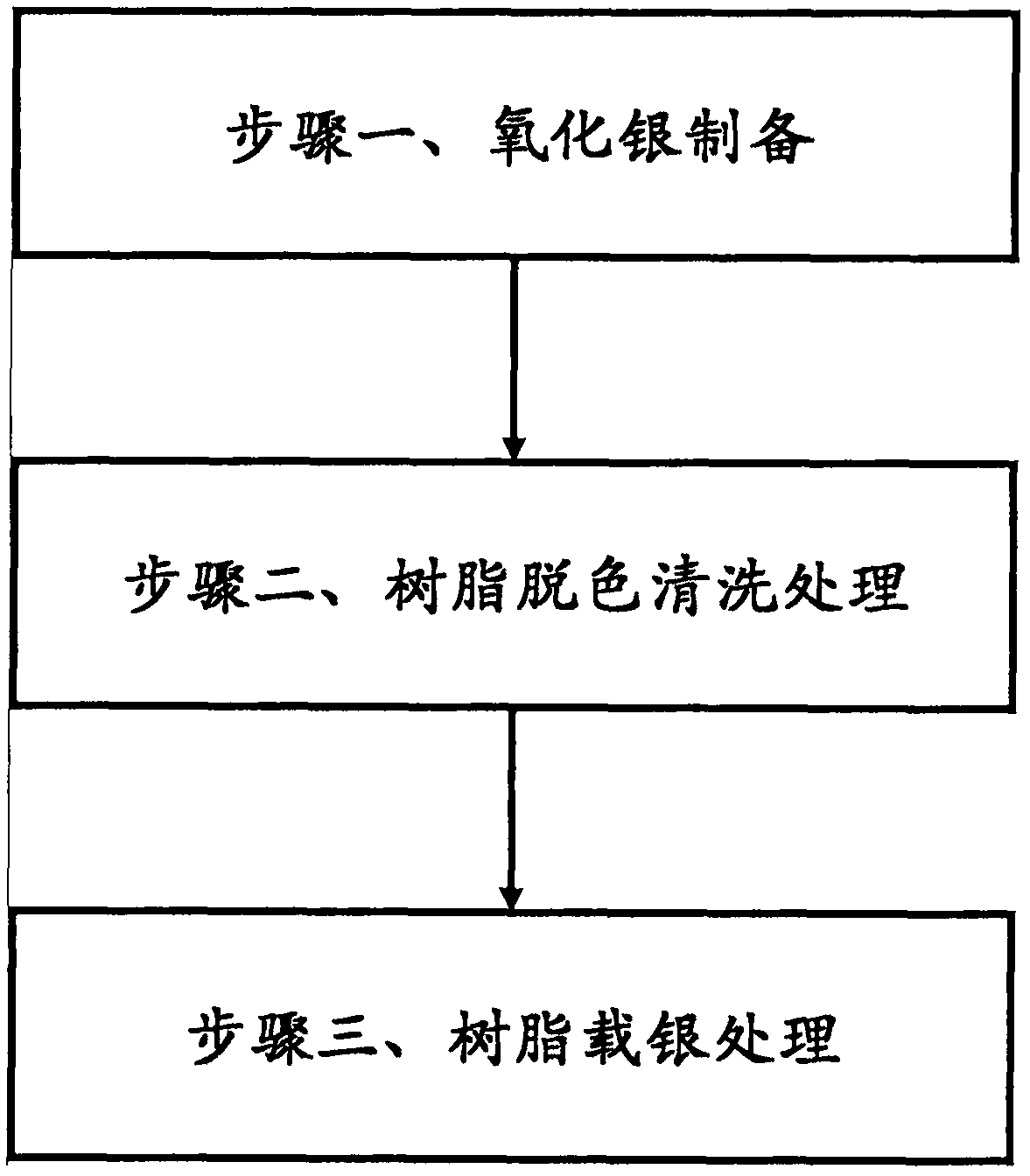

[0048] A kind of production technology of acetic acid deiodination silver-loaded resin adsorbent, comprises the steps,

[0049] Step 1, silver oxide preparation

[0050] 1) Add deionized water into the reaction kettle, heat it to boiling, and maintain it under boiling conditions for 15 minutes to remove CO in the deionized water 2 , to get the removal of CO 2 of deionized water;

[0051] 2), dissolving NaOH in CO removal 2 In deionized water, it was made into a solution with a mass fraction of 25%; it was left to cool to room temperature, and after filtration, the filtrate was obtained, i.e. sodium hydroxide solution, for subsequent use;

[0052] 3), the AgNO 3 dissolved in CO removal 2 in deionized water, let stand and cool to room temperature, and obtain the filtrate after filtration, i.e. silver nitrate solution, for subsequent use;

[0053] 4), under cooling condition, described silver nitrate solution is added dropwise in described sodium hydroxide solution, wherein...

Embodiment 2

[0062] A kind of production technology of acetic acid deiodination silver-loaded resin adsorbent, comprises the steps,

[0063] Step 1, silver oxide preparation

[0064] 1) Add deionized water into the reaction kettle, heat it to boiling, and maintain it under boiling conditions for 20 minutes to remove CO in the deionized water 2 , to get the removal of CO 2 of deionized water;

[0065] 2), dissolving NaOH in CO removal 2 In deionized water, it was made into a solution with a mass fraction of 40%; it was left to cool to room temperature, and after filtration, the filtrate was obtained, i.e. sodium hydroxide solution, for subsequent use;

[0066] 3), the AgNO 3 dissolved in CO removal 2 in deionized water, let stand and cool to room temperature, and obtain the filtrate after filtration, i.e. silver nitrate solution, for subsequent use;

[0067] 4), under cooling condition, described silver nitrate solution is added dropwise in described sodium hydroxide solution, wherein...

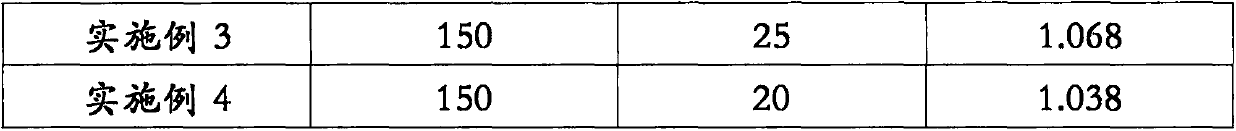

Embodiment 3

[0078] A kind of production technology of acetic acid deiodination silver-loaded resin adsorbent, comprises the steps,

[0079] Step 1, silver oxide preparation

[0080] 1) Add deionized water into the reaction kettle, heat it to boiling, and maintain it under boiling conditions for 10 minutes to remove CO in the deionized water 2 , to get the removal of CO 2 of deionized water;

[0081] 2), dissolving NaOH in CO removal 2 In deionized water, it was made into a solution with a mass fraction of 45%; it was left to cool to room temperature, and after filtration, the filtrate was obtained, i.e. sodium hydroxide solution, for subsequent use;

[0082] 3), the AgNO 3 dissolved in CO removal 2 in deionized water, let stand and cool to room temperature, and obtain the filtrate after filtration, i.e. silver nitrate solution, for subsequent use;

[0083] 4), under cooling condition, described silver nitrate solution is added dropwise in described sodium hydroxide solution, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com