Non-welding fixing equipment for low-pressure pipeline small-pore-diameter bore-opening machine

A technology for fixed equipment and low-pressure pipelines, which is applied in the field of small-aperture opening machines for medium and low-pressure pipelines without welding and fixed equipment. It can solve the problems of open technical solutions, low safety, and small scope of application, so as to ensure safety and simple device installation. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

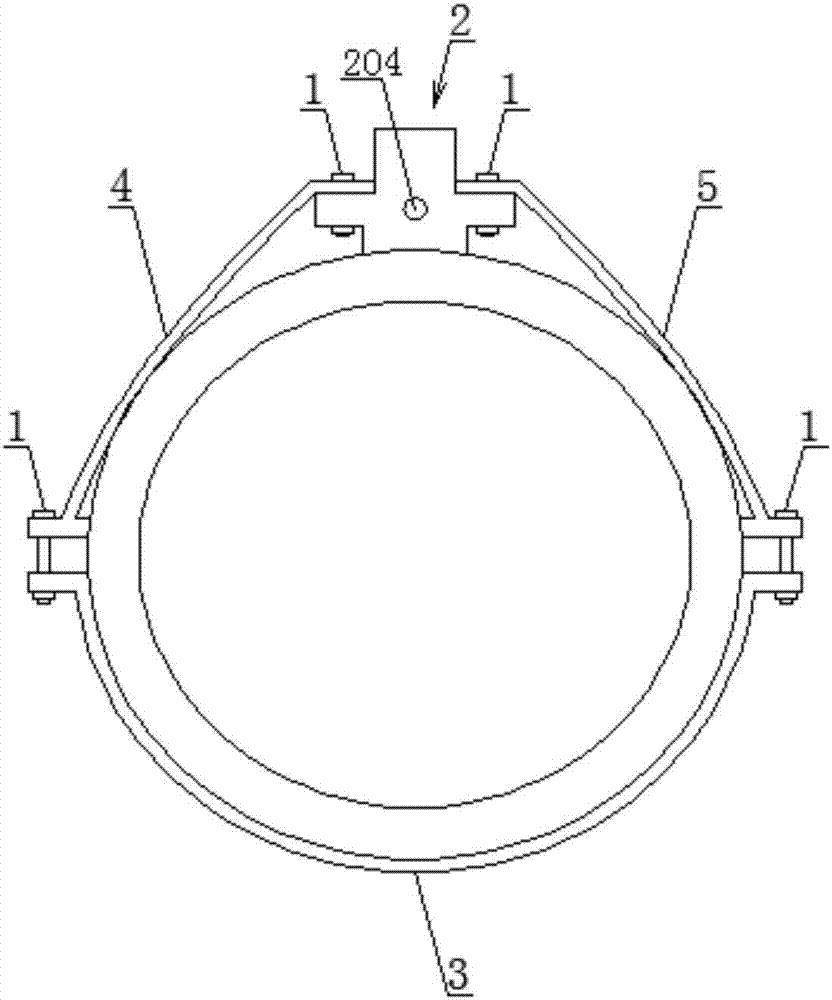

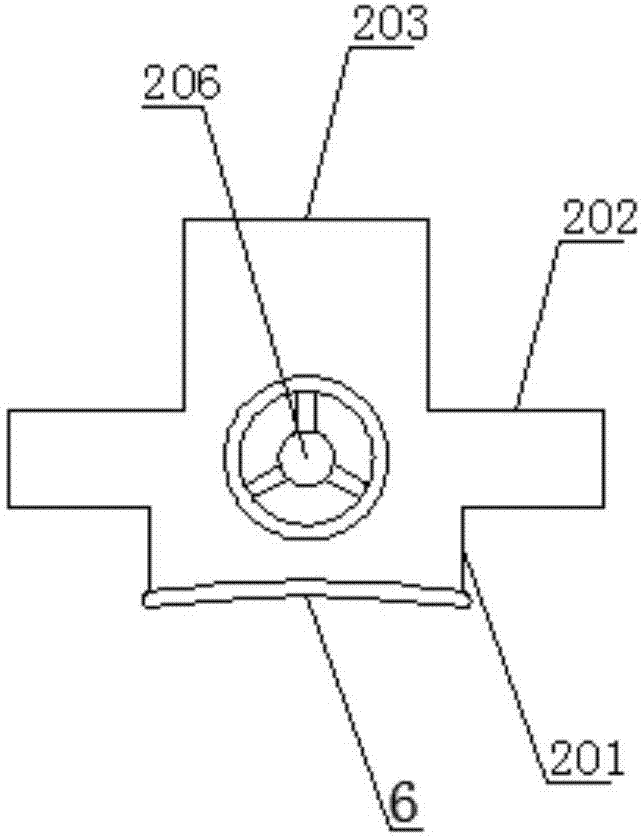

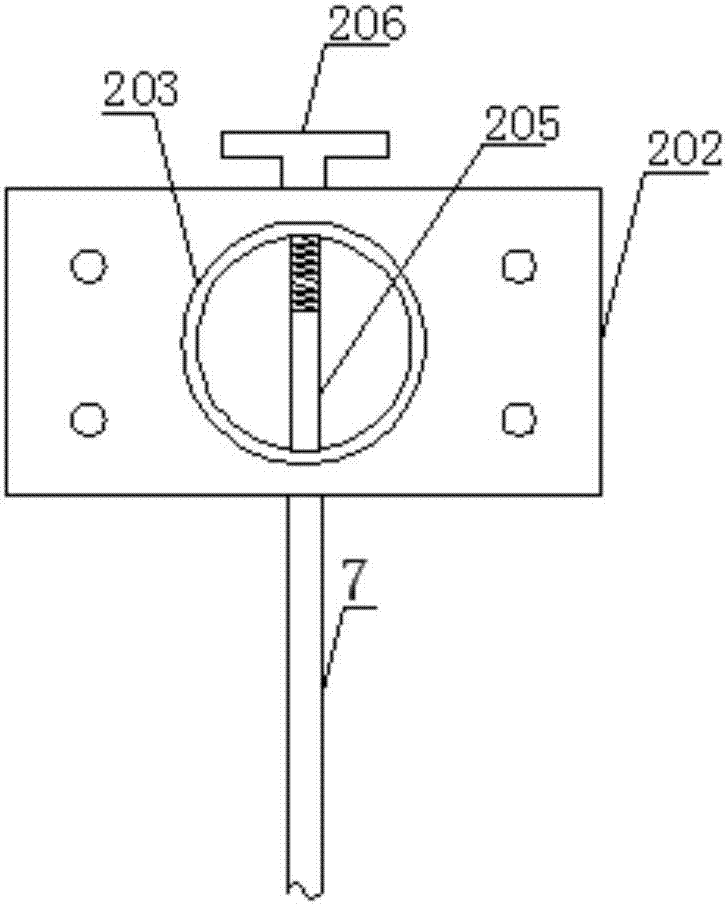

[0036] In a specific embodiment, such as figure 1 , 2 As shown in , 3, the small-diameter hole tapping machine for medium and low pressure pipelines has no welding fixed equipment, including a puppet device 2 and a detachable and fixed installation of the pup joint device 2 on the pipeline part of the pipeline to be drilled or the valve to be drilled The gripping device on the outer surface of the

[0037] Such as figure 1 , 2 , 3, the pup joint device 2 includes a tubular seat body 201, a body 202 fixed on the seat body 201, and a tubular body 203 fixed on the body 202. The channel communicates with the seat body 201 and the tube body 203 respectively. The body 202 is provided with a pressure relief through hole 204 , one end of the pressure relief throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com