Hydraulic diaphragm metering pump with diaphragm protection function

A diaphragm metering pump and protective membrane technology, applied to pumps with flexible working elements, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as shear damage, metering pump failure, damage, etc., to achieve The effect of stable work performance, stable connection relationship, and stable work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

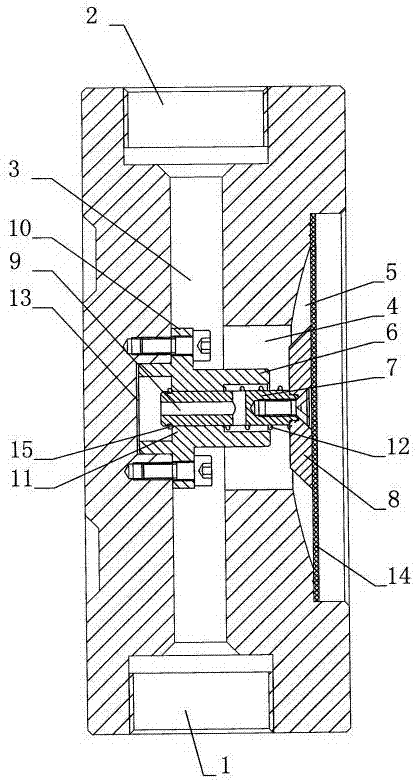

[0014] The hydraulic diaphragm metering pump with protective film function is provided with a pump head, such as figure 1 As shown, the pump head is provided with a liquid inlet 1, a liquid outlet 2, a medium channel 3, a connecting hole 4, and a medium cavity 5. The liquid inlet 1 and the liquid outlet 2 are located on both sides of the pump head, respectively, and the liquid inlet 1 and the liquid outlet 2 are communicated through a medium channel 3 . A medium cavity 5 is provided on one side of the pump head, and the medium cavity 5 is connected with the medium channel 3 through the connecting hole 4 . Therefore, the liquid inlet 1, the liquid outlet 2, the medium channel 3, the connecting hole 4, and the medium cavity 5 communicate with each other and form a T-shaped cavity.

[0015] There is also a protective film assembly inside the pump head, such as figure 1 As shown, the protective film assembly includes a protective film valve core and a protective film valve sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com