Construction method of screw drilling and squeezing cast-in-place pile and combined screw drill

A construction method and cast-in-situ pile technology, which is applied in the direction of drill bits, sheet pile walls, drilling equipment, etc., can solve the problem that the drilling capacity of bored cast-in-place piles cannot be driven in, which affects the quality of piles and the cost of pile foundations, and the difficulty of punching cast-in-situ piles. Hole collapse and other problems, to achieve the effect of strong constructability, high construction efficiency, and small settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

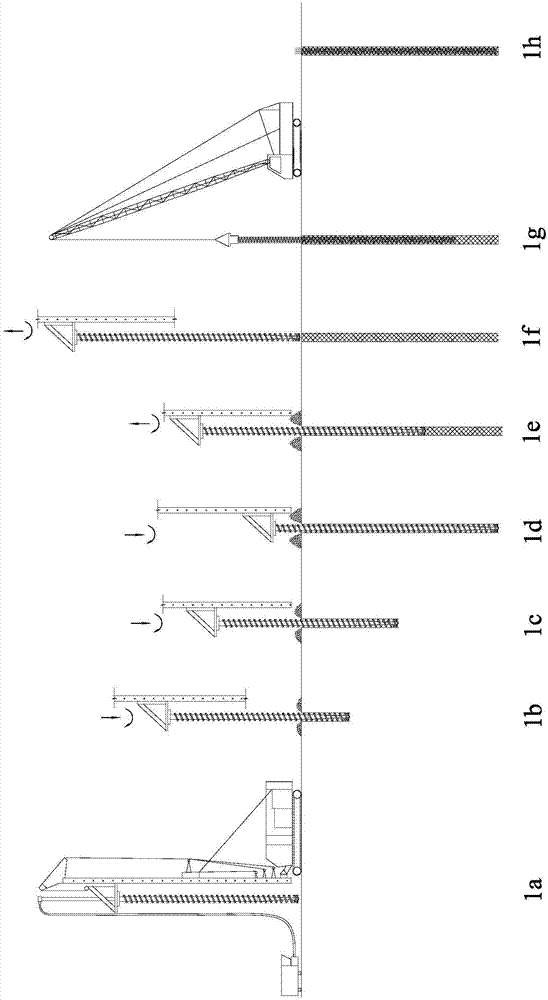

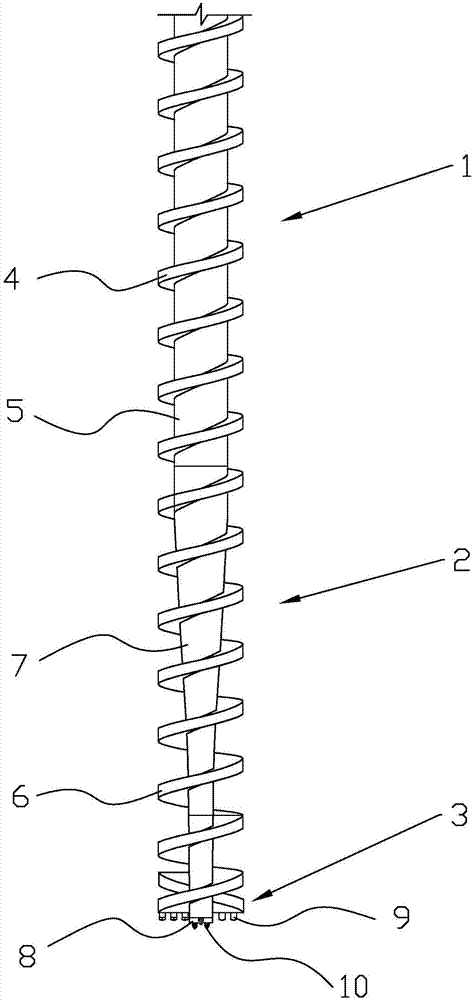

[0035] Such as figure 1 middle figure 1 Shown in a ~ 1h, the construction method of the screw-drilled cast-in-place pile of the present invention comprises the following construction steps:

[0036] 1) The pile drill rig equipped with the combined screw drill bit is put in place according to a known method, the concrete pump is prepared, and the pile material to be poured is prepared. Conventional piles are concrete or cement fly ash gravel piles and the like.

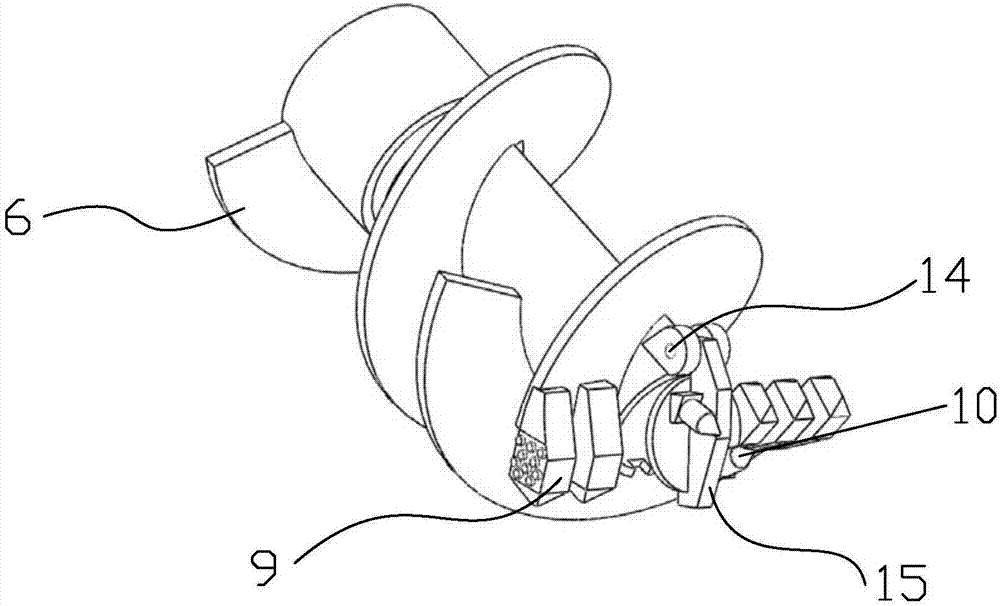

[0037] 2) After the pile drilling rig with the combined screw drill bit is in place, start the pile drilling rig to apply clockwise torque and downward axial pressure, and use the combined screw drill bit to drill and extrude the hole. During the process, the soil loosened by rotary drilling is transported to the surface through the rotating motion of the helical blade on the drill bit system, and part is gradually squeezed into the side wall of the pile hole. The pile hole drilling and squeezing process in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com