Special equipment for degrading sewage COD (Chemical Oxygen Demand) and control method of special equipment

A technology for degrading sewage and special equipment, which is applied in the field of sewage treatment equipment, can solve the problems of high ozone cost, achieve long-lasting effect, reduce treatment cost, and avoid disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

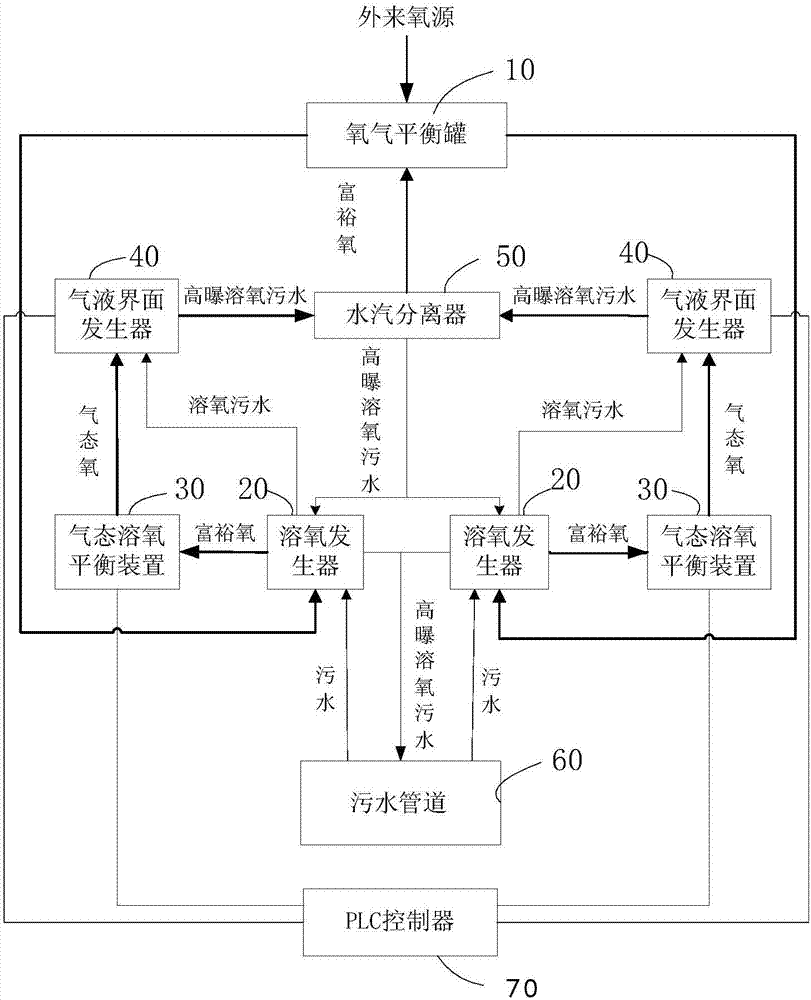

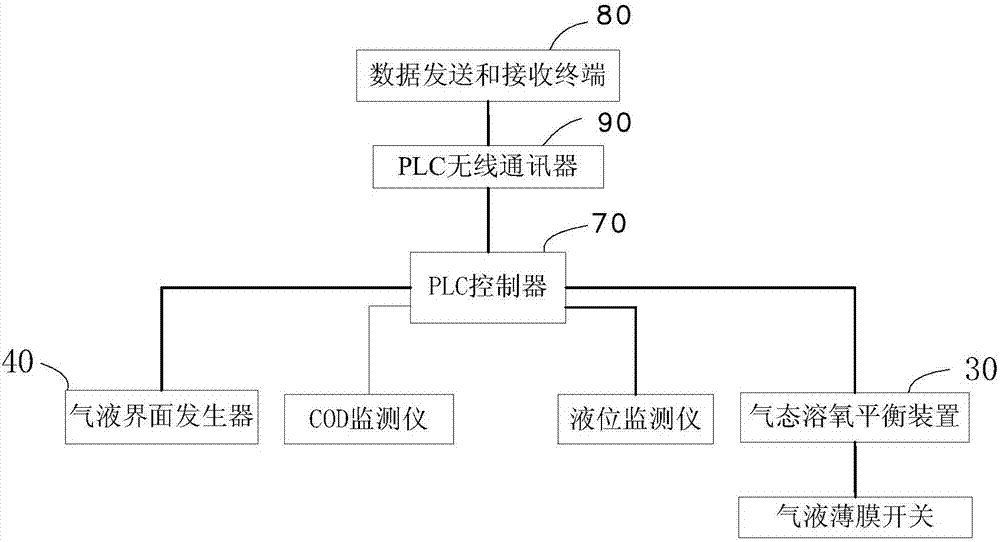

[0073] A special equipment for degrading sewage COD, the equipment includes: two high exposure dissolved oxygen sewage preparation equipment and PLC.

[0074] The high-exposure dissolved oxygen sewage preparation equipment includes: an oxygen balance tank 10 , a dissolved oxygen generator 20 , a gaseous dissolved oxygen balance device 30 , a gas-liquid interface generator 40 and a water vapor separator 50 .

[0075] The oxygen balance tank 10 is connected to the dissolved oxygen generator 20, the dissolved oxygen generator 20 is connected to the gaseous dissolved oxygen balance device 30, the gaseous dissolved oxygen balance device 30 is connected to the gas-liquid interface generator 40, and the gas-liquid interface generator 40 is separated from the water vapor The water vapor separator 50 is connected with the dissolved oxygen generator 20 and the oxygen balance tank 10 . The gaseous dissolved oxygen balance device 30 is arranged on the oxygen balance tank 10 .

[0076] A ...

Embodiment 2

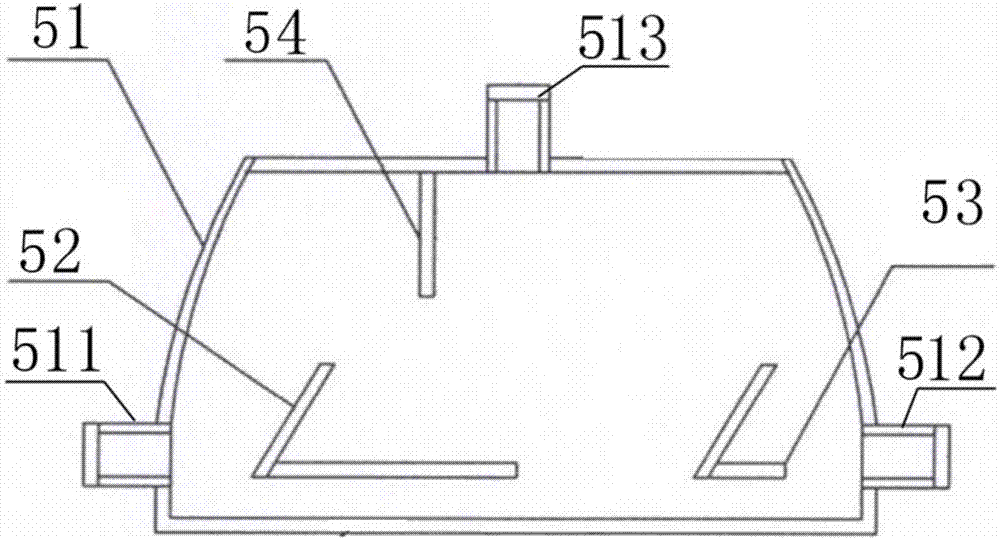

[0085] A special equipment for degrading sewage COD, which is basically the same as the equipment in Embodiment 1, the difference lies in the structure of the water vapor separator 50.

[0086] Such as Figure 4 As shown, the water vapor separator 50 includes: a separator vessel 51 connected with the gas-liquid interface generator 40 and the dissolved oxygen generator 20 . The separator container 51 is provided with: a water inlet 511 , a water outlet 512 and an exhaust port 513 .

[0087] The water inlet 511 is arranged on the bottom of the separator container 51, and the water outlet 512 is arranged on the side of the separator container 51, and the end of the pipeline provided on the water inlet 511 is higher than the height of the water inlet 511 at the side of the separator container 51. The water inlet 511 communicates with the gas-liquid interface generator 40 through a pipeline. The water outlet 512 communicates with the dissolved oxygen generator 20 through a pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com