Anti-rollover system and method for lorry-mounted crane

A truck-mounted crane and anti-overturning technology, applied in cranes and other directions, can solve the problems of automation, low safety, and few further problems, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

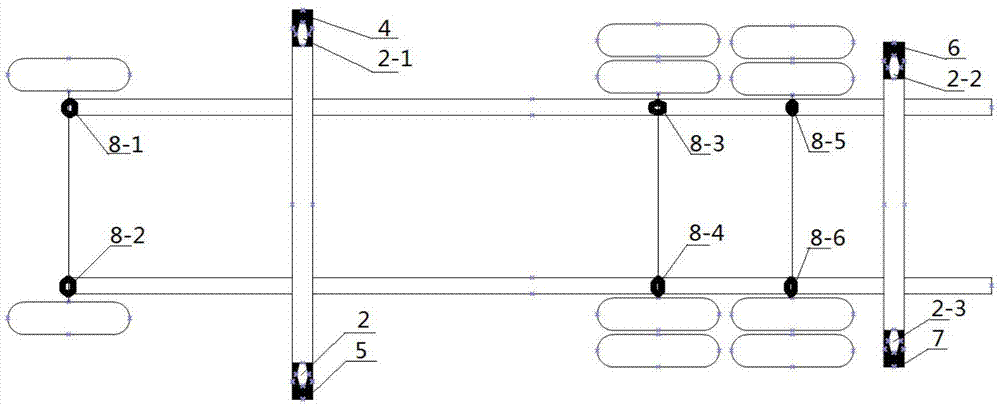

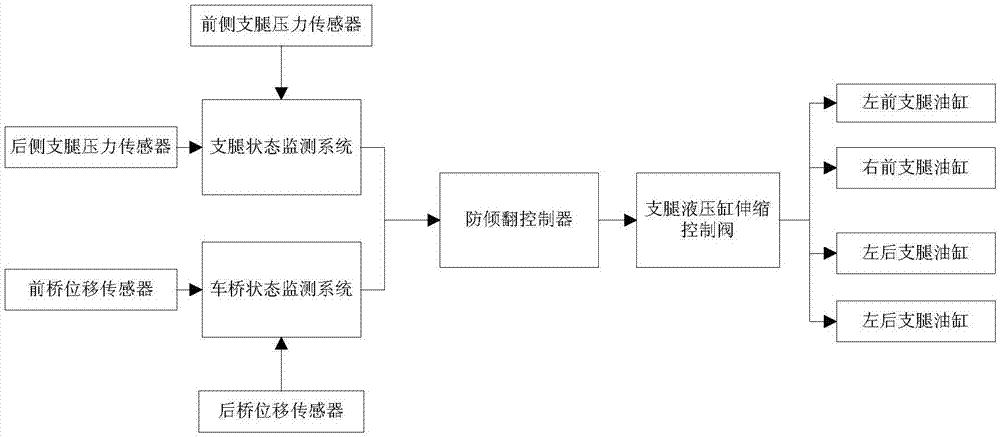

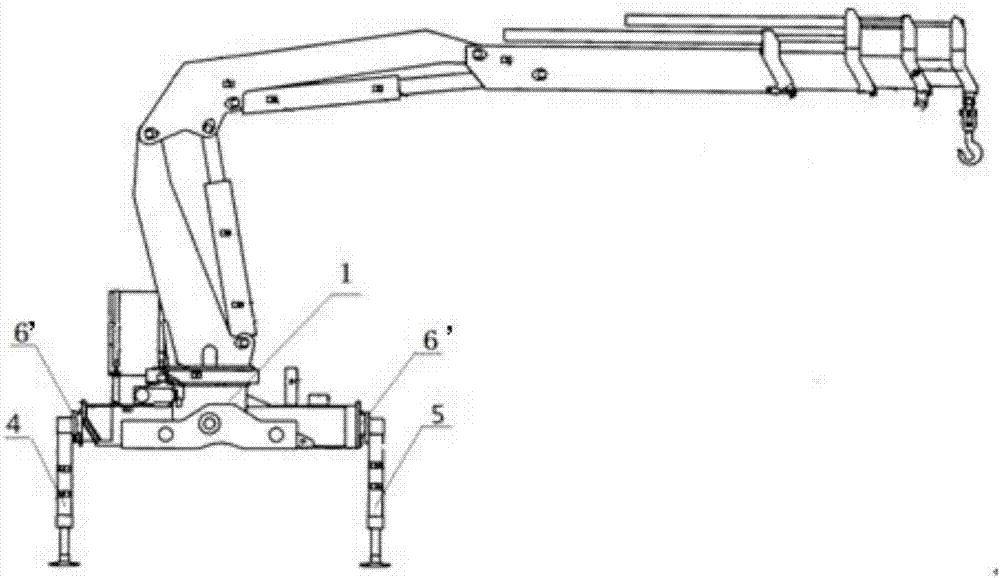

[0022] according to Figure 1-3 , the present invention designs an active anti-tipping system for a truck-mounted crane. The system involves a hydraulic outrigger pressure detection unit, an axle position detection unit, an anti-tipping control system, an independent hydraulic outrigger control unit, an alarm system, etc., and the arrangement position Such as figure 1 As shown, the anti-rollover system consists of figure 2 As shown, the mutual cooperation between the above components can realize the active anti-overturning of the truck-mounted crane.

[0023] In an active anti-tipping system for a truck-mounted crane, the hoisting base is installed on the chassis frame of a car, and the horizontal outrigger 6' is installed inside the hoisting base, and the horizontal outrigger 6' can be extended outwards under the drive of a hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com