A thin film structure that folds automatically and directionally under thermal excitation

A thin-film structure and heat-activated technology, applied in the field of isotropic heat-deformable materials, can solve the problems of uncontrollable bending direction and low precision, and achieve the effect of realizing crease position and folding direction, realizing precise control and simplifying preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

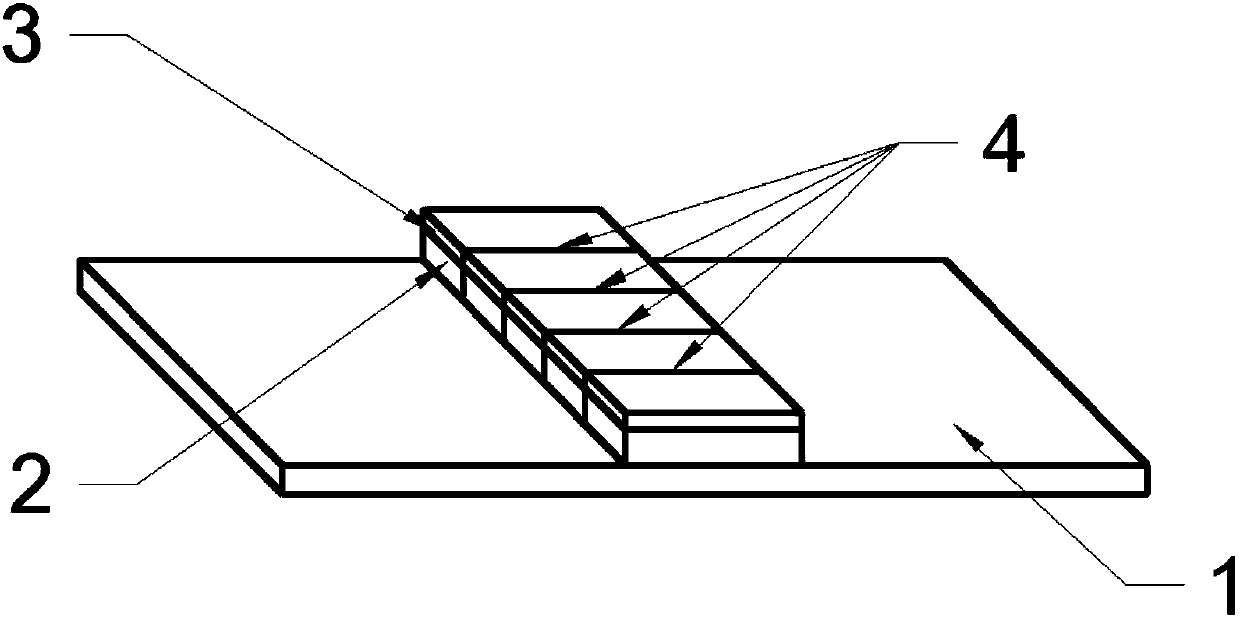

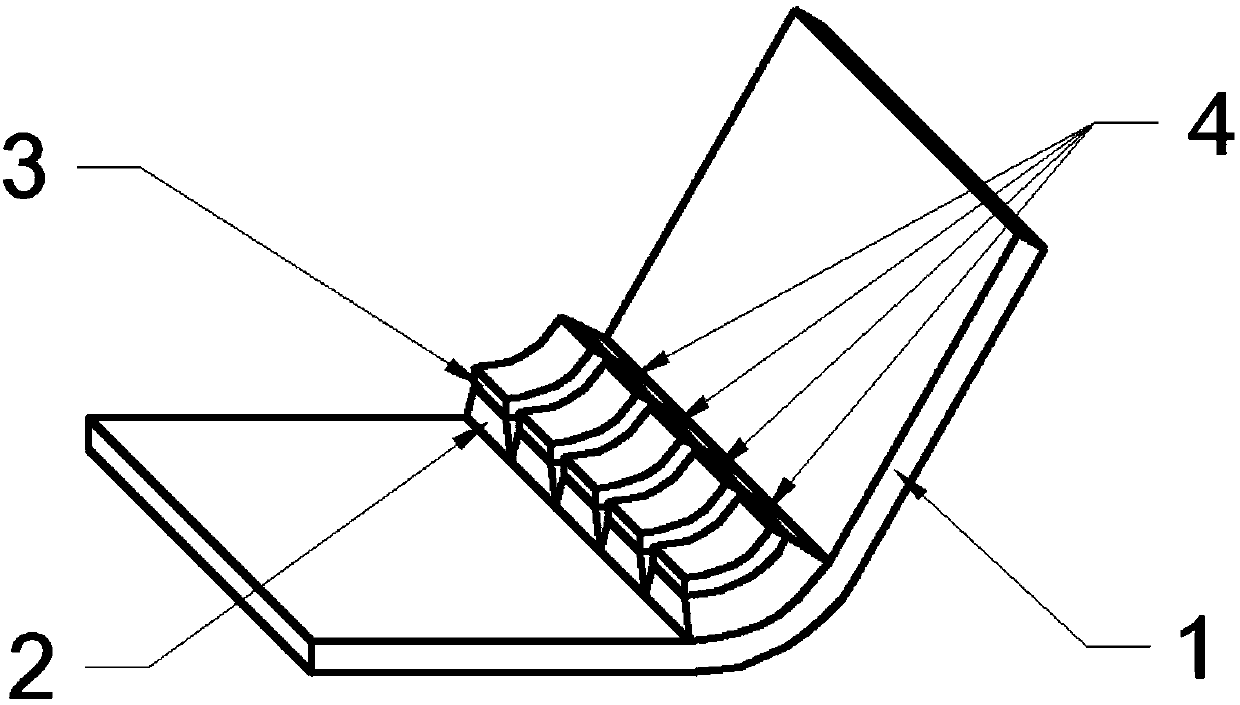

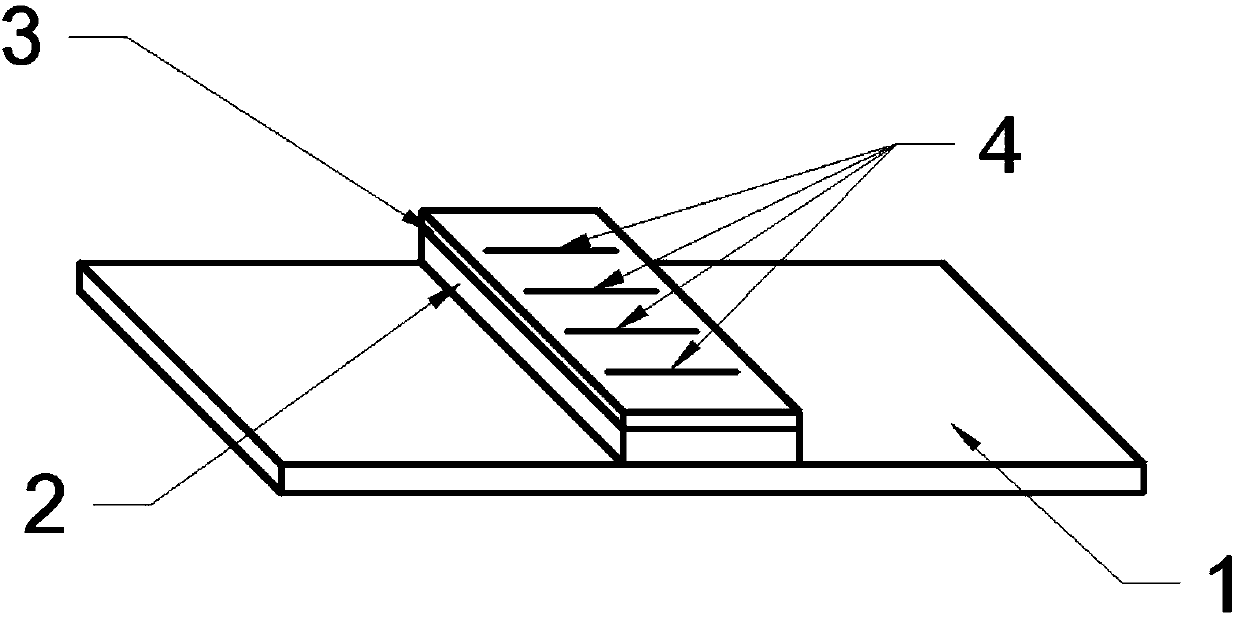

[0017] Specific Embodiment 1: In this embodiment, a film structure that is automatically orientated and folded under thermal excitation includes a base 1, a flexible adhesive 2, a thermally deformable film 3, and a number of slits 4; wherein the flexible adhesive 2 is arranged on the base along the crease 1, the thermally deformable film 3 covers the flexible adhesive 2; several slits 4 are perpendicular to the creases, and completely penetrate the thermally deformable film 3 and the flexible adhesive 2 in the depth direction.

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the distance between two adjacent slits 4 is smaller than the width of the heat-deformable film 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the distance between two adjacent slits 4 is one-third of the width of the heat-deformable film 3 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap