Punching die for removing bur of tubular product

A technology for tubular products and punching dies, applied in metal processing and other directions, can solve problems such as product scrapping, and achieve the effects of improving processing efficiency, improving product qualification rate and accurate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

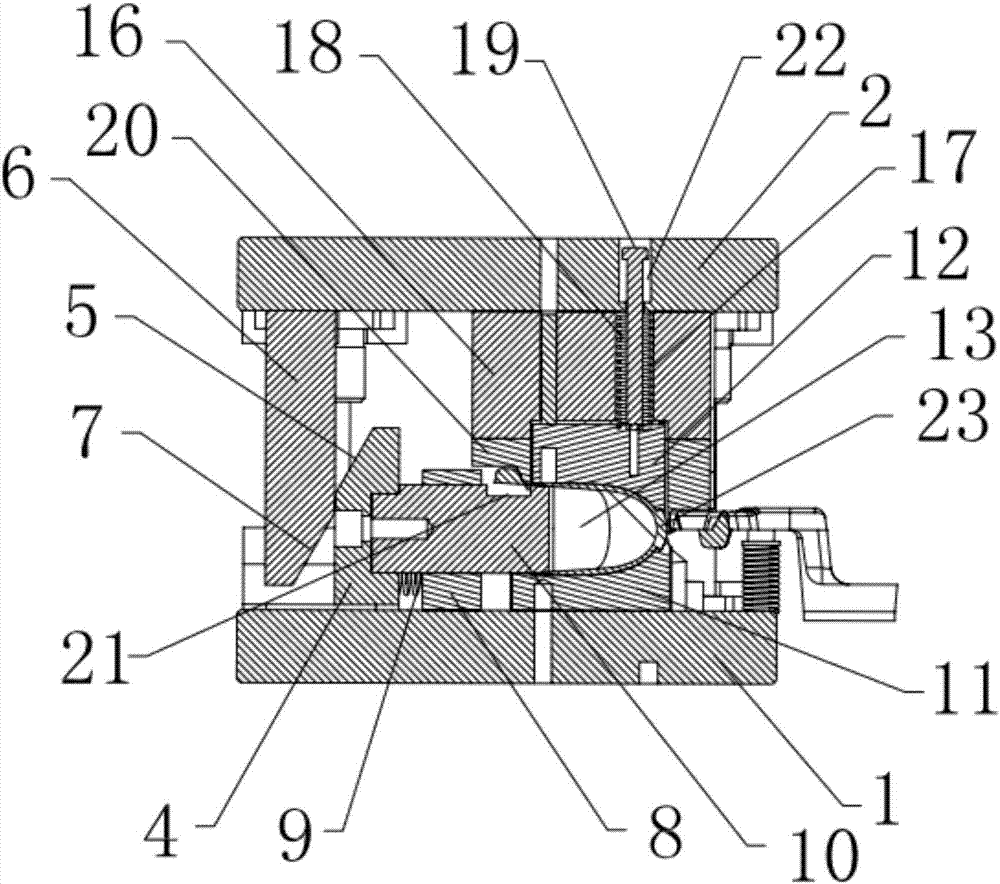

[0026] In the mold-opening state, the tubular product 23 is placed on the upper end of the product positioning seat 11 .

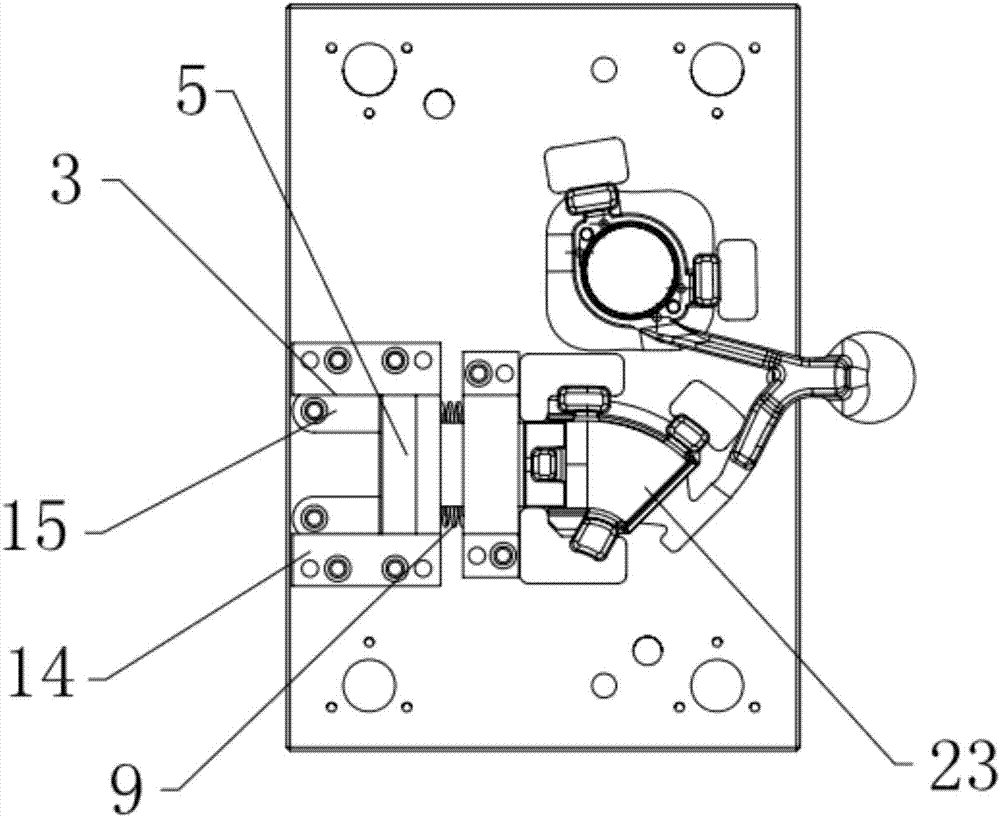

[0027] Further, the upper die push plate 6 moves downward with the upper die base 2, and drives the lower die push plate 4 to slide inward along the guide groove 3 through the cooperation of the second inclined surface 5 and the first inclined surface 7, and then the side blade 10 moves along the guide groove 3. The guide block 8 slides in the direction of the cavity 22 , and at the same time, the product discharge plate 12 abuts against the upper end of the tubular product 23 under the action of the guide rod 19 and the spring 18 .

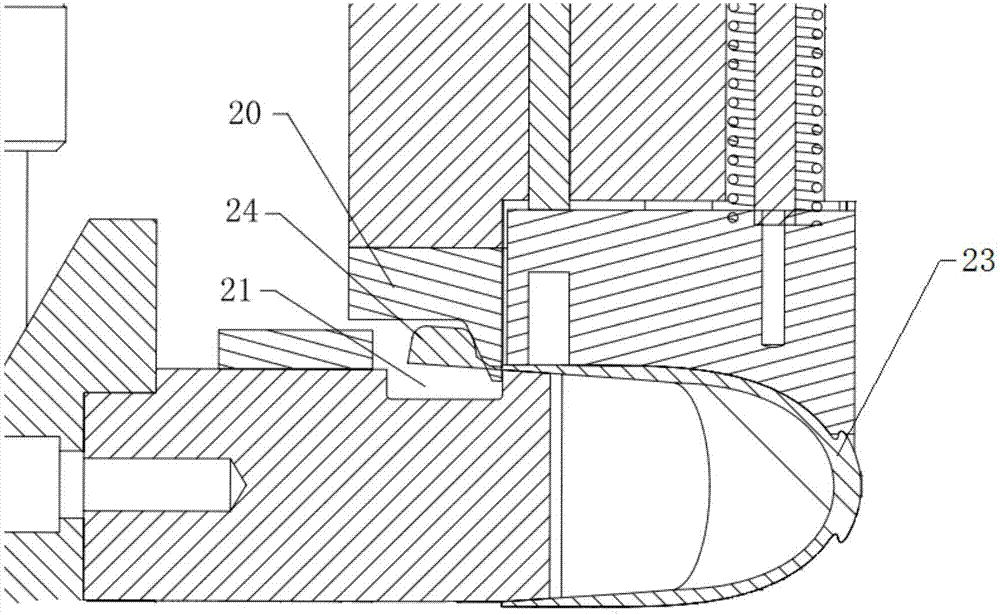

[0028] Further, when the groove 21 runs below the main cutting edge 20 along with the side cutting edge 10, the side cutting edge 10 punches off the inner wall of the tubular product 23 and supports the tubular product 23. The slag bag 24 of the tubular product 23 is punched out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com