Pressure determination in a fuel injection valve

A pressure and fuel technology, applied in the direction of fuel injection control, electrical control, machine/engine, etc., can solve the problem of insufficient accuracy of pressure measurement, and achieve the effect of improving injection accuracy, avoiding emissions, and accurate pressure determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

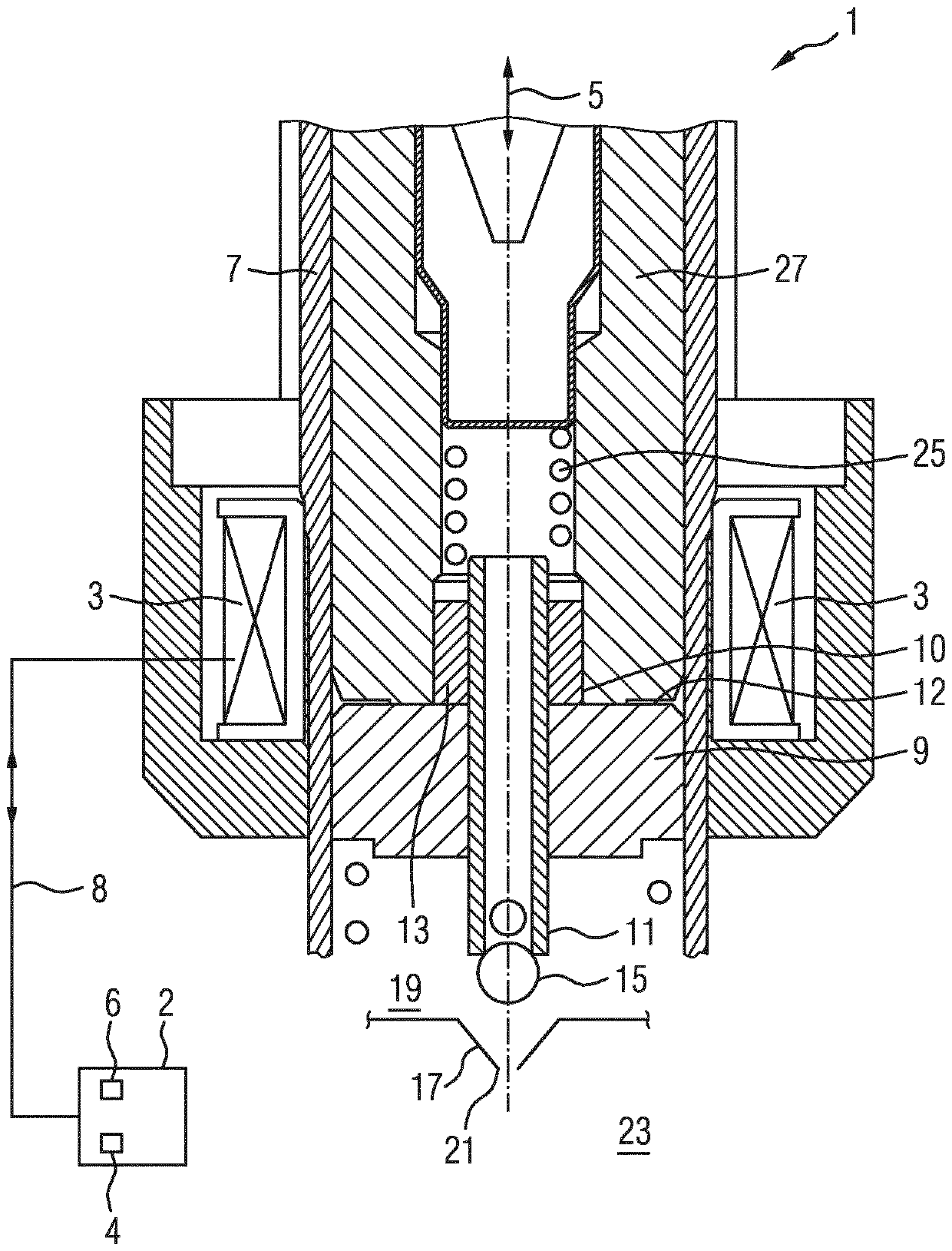

[0045] figure 1 The solenoid valve 1 shown in schematic cross-sectional view in , has a coil 3 to which a voltage can be applied, so that current flows through the coil 3 in order to build up a magnetic field. In this context, the magnetic field extends substantially in the longitudinal direction 5 of the guide cylinder 7 . The magnetic field acts on the ferromagnetic armature 9 which can move within the guide cylinder 7 . By moving the armature 9 it is possible to move the closing element or the nozzle needle 11 of the solenoid valve 1 in the longitudinal direction 5 , in particular by making contact between the armature 9 and the annular drive element 13 which is fixedly connected to the closing element 11 .

[0046] exist figure 1 In the open state shown in , the closing ball 15 constituted by a conical seat 17 is drawn back so that fuel 19 can pass through the opening 21 in the seat into the combustion chamber 23 for combustion. In the fully open state, the armature 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com