Hand-operated electric wire pipe threading device and its threading method

A technology of threading device and threading method, which is applied in the direction of cable laying equipment, etc., can solve the problems of labor and material waste, low efficiency, and influence on construction progress, and achieve the effect of saving materials, saving labor resources, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

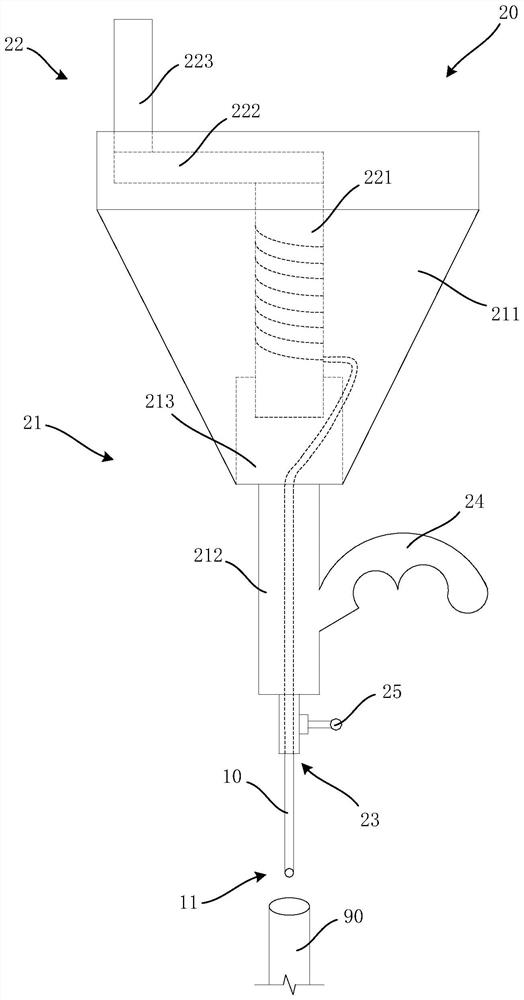

[0034] refer to figure 1 , the present invention provides a hand-operated electric wire pipe threading device, which is used for threading electric wires into electric wire pipes pre-buried in buildings. The construction progress also caused the problem of labor and material waste.

[0035] The hand-operated wire pipe threading device of the present invention will be described below in conjunction with the accompanying drawings.

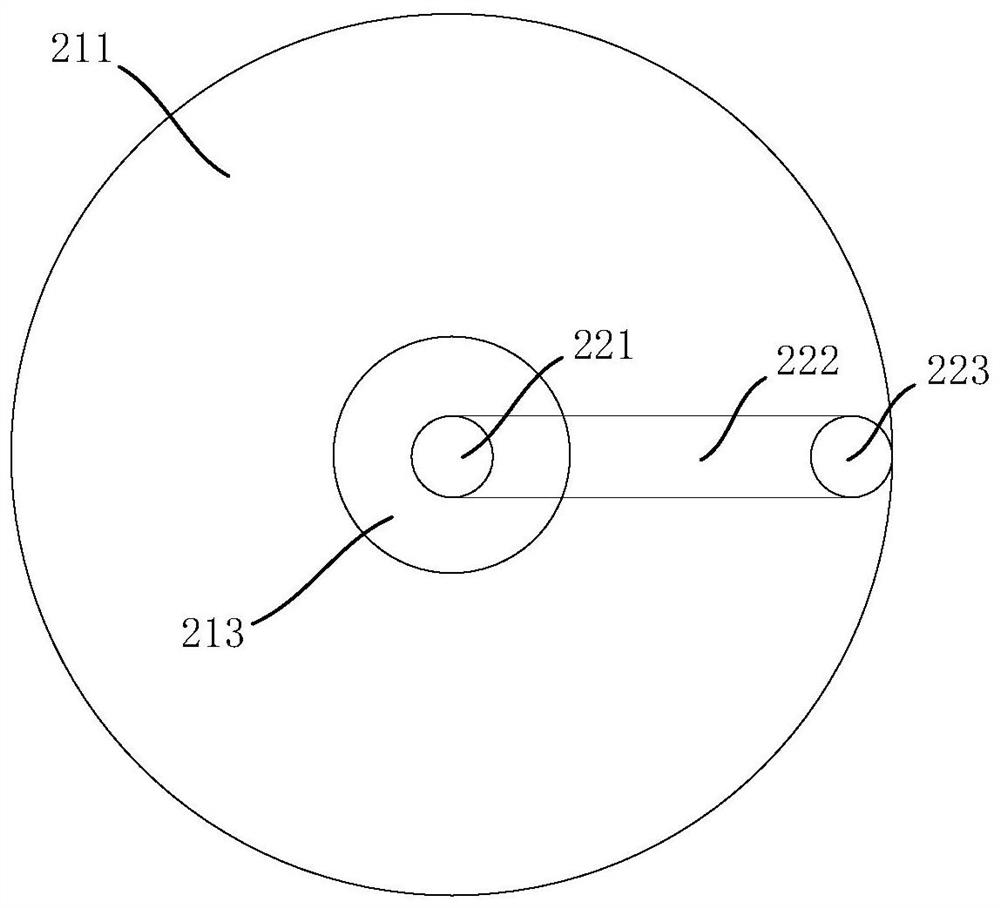

[0036] like figure 1 and figure 2 As shown, the hand-operated wire conduit threading device of the present invention includes a metal wire 10 and a containing box 20 .

[0037] Wherein, the metal wire 10 is coiled into a spiral structure, and the metal wire has a first end 11 and a second end located at the center of the helix, and the first end 11 forms a spherical structure, which is used to reduce the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com