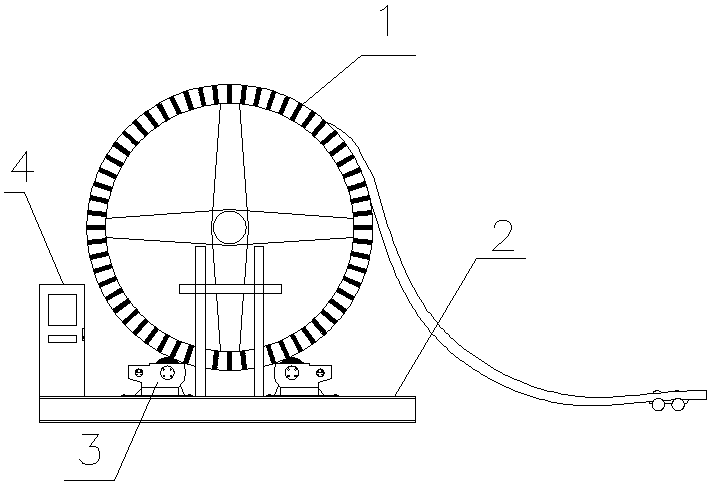

PLC control-based ultrahigh-voltage cable laying device

A cable laying and ultra-high voltage technology, applied in the direction of cable laying equipment, etc., can solve the problems of changing the speed of the cable reel, the cable bears greater tension, personnel and equipment damage, etc., to improve the speed, reduce the probability of cable damage, The effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

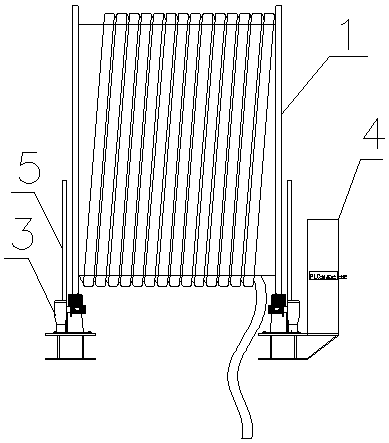

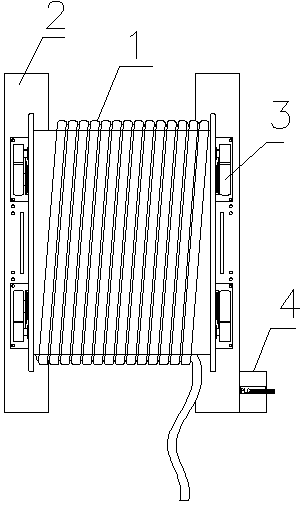

[0023] An ultra-high voltage cable laying device based on PLC control, including a cable reel 1 and a cable reel frame 2, the cable reel 1 is rotatably installed on the cable reel frame 2, and the cable reel 2 is equipped with PLC frequency conversion The control cabinet 4 and two sets of driving devices 3, the driving devices 3 are fixedly installed on the lower end of the cable reel 1 on the cable reel frame 2, and the two groups of driving devices 3 are symmetrically arranged on the cable reel frame 2 on both sides of the axis of the cable reel 1, The driving device 3 drives the cable reel 1 to rotate, and the driving device 3 is electrically connected with the PLC frequency conversion control cabinet 4 .

[0024] The driving device 3 includes two rollers 31 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com