Window layer, CdTe thin-film solar cell assembly and preparation method of CdTe thin-film solar cell assembly

A solar cell and window layer technology, applied in the field of solar cells, can solve the problems affecting the open circuit voltage and fill factor of battery components, reduce the intensity of sunlight incident on the absorbing layer, reduce the short circuit current of battery components, etc., and achieve high open circuit voltage and Fill Factor, Transparency Improvement, Open Circuit Voltage and Effect of Fill Factor Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing a CdTe thin film solar cell module, comprising: epitaxially growing a transparent conductive film, a window layer, a light absorption layer, a back contact layer and a back electrode layer on a substrate from bottom to top; the window layer for Mg x Cd 1- x S y o 1-y layer, wherein, 0<x<1, 0<y<1; the light absorbing layer is a CdTe layer.

[0033]According to the present invention, preferably, the epitaxial growth method of the window layer is selected from one or more of magnetron sputtering, water bath deposition and thermal diffusion. More preferably, the epitaxial growth method of the window layer is magnetron sputtering, water bath deposition or thermal diffusion.

[0034] According to the present invention, the preparation method further includes: epitaxially growing a barrier layer on the substrate, and the transparent conductive film layer is epitaxially grown on the barrier layer.

[0035] Accordi...

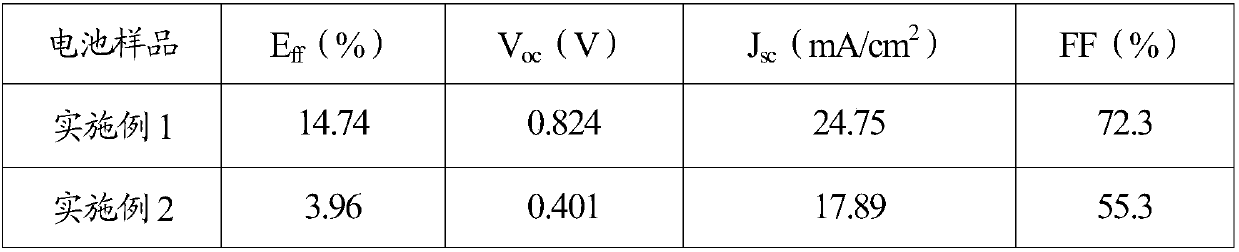

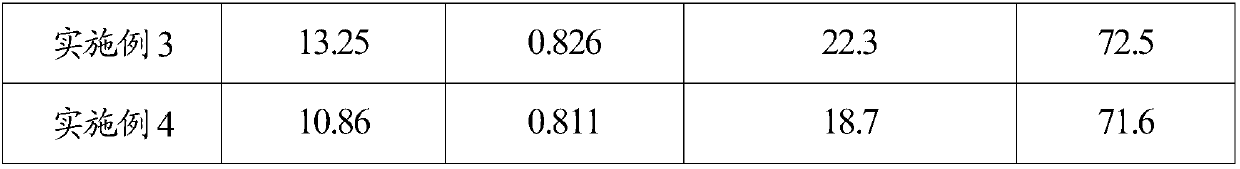

Embodiment 1

[0037] A window layer for Mg x Cd 1-x S y o 1-y layer, wherein 0

[0038] A CdTe thin-film solar cell module, comprising a substrate, characterized in that an epitaxial stack is arranged on the substrate, and the epitaxial stack sequentially includes: a barrier layer, a transparent conductive film, a high resistance layer, In this embodiment, the above-mentioned window layer, light absorbing layer, back contact layer and back electrode layer.

[0039] The substrate described in this embodiment is made of soda-lime glass; the barrier layer is SiO 2 layer; the transparent conductive film is an FTO film layer; the high-resistance layer is a ZnO layer, and the thickness of the high-resistance layer is 50nm; the light-absorbing layer is a CdTe layer; the back contact layer is a ZnTe layer, so The back electrode layer is a Mo / Al / Cr layer. The thickness of the Mo layer in the back electrode layer is 20nm, the thickness of t...

Embodiment 2

[0042] This embodiment is the same as Embodiment 1 except for the following features: the thickness of the window layer is 2 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com