Dip-mode etching device and dip-mode etching method

An etching equipment and etching technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven flow of etching liquid, low etching efficiency, and inaccurate judgment results, so as to avoid product mura and improve etching efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with the embodiments of the present invention and the accompanying drawings.

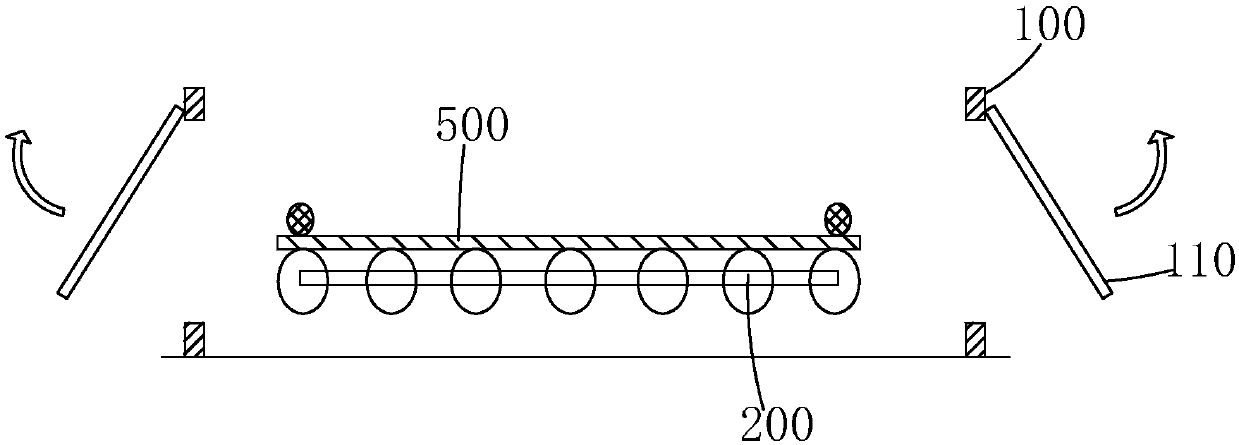

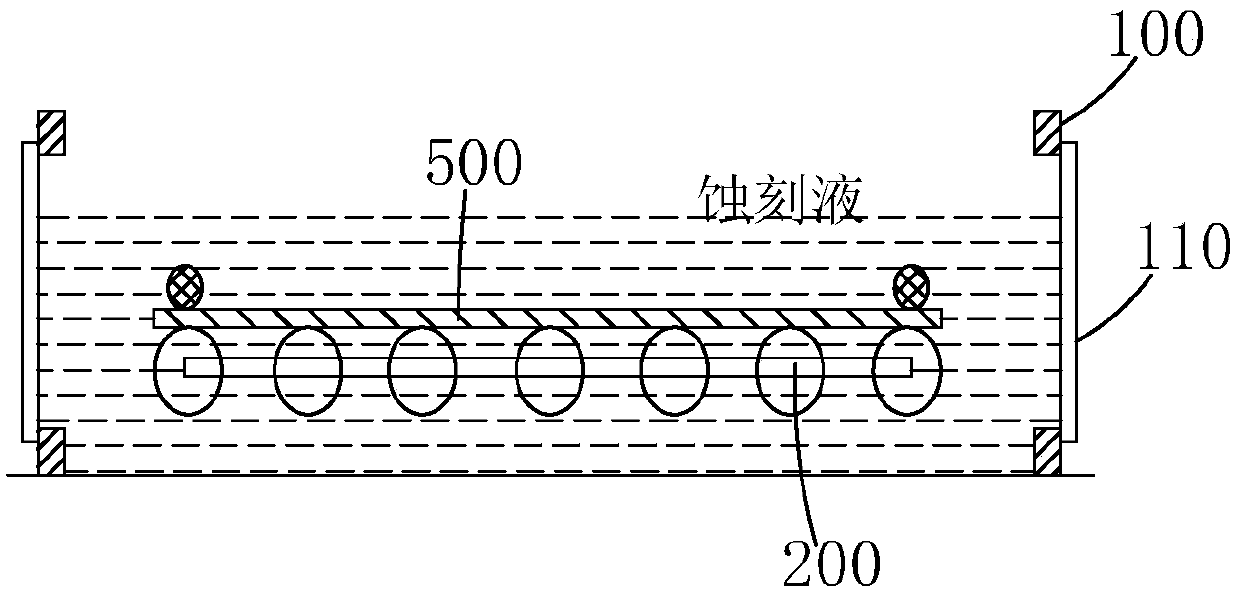

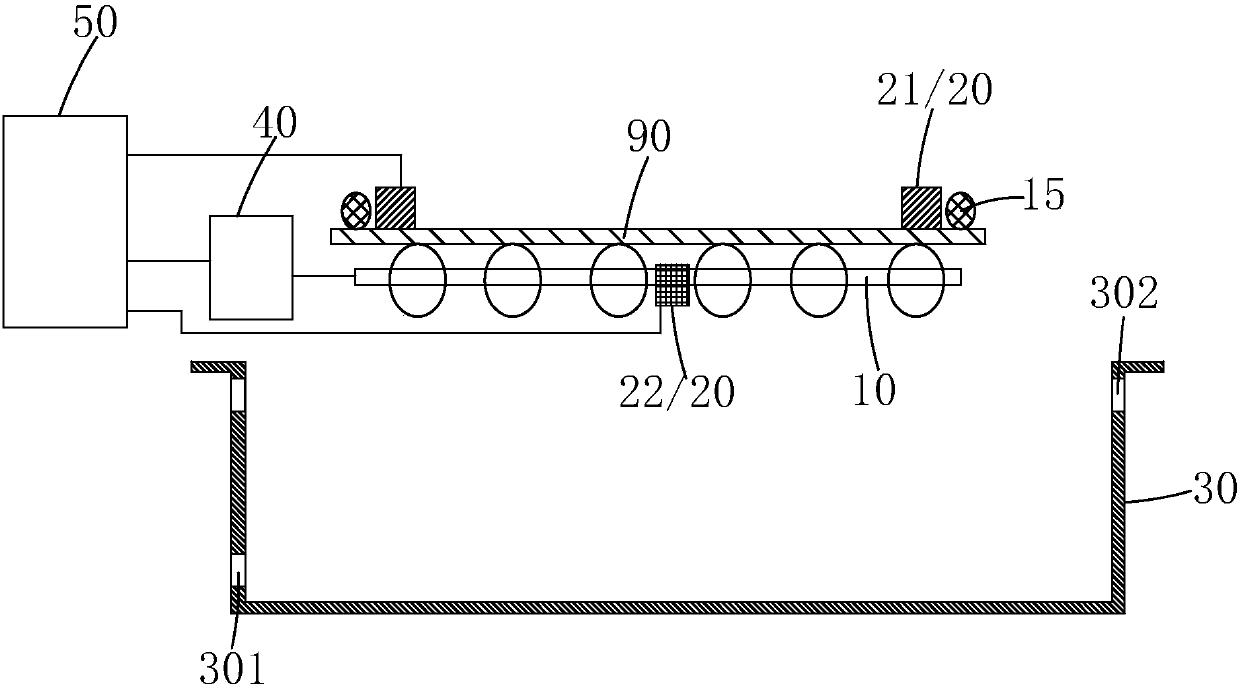

[0038] see image 3 , the present invention provides an immersion etching equipment, comprising a carrier 10 for carrying a substrate 90, a sensor 20 arranged on the carrier 10 and used to determine the end point of etching, and a sensor 20 arranged under the carrier 10 for An etching tank 30 for containing the etching solution and the substrate 90;

[0039] The lower end of the etching tank 30 is provided with a plurality of liquid inlets 301 for delivering the etching solution in the etching tank 30, and the upper end of the etching tank 30 is provided with a plurality of drains for discharging the excess etching solution in the etching tank 30. Liquid port 302;

[0040] The carrying table 10 can move vertically and horizontally, and the carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com