A corrosion-resistant insulated overhead cable

An overhead cable and corrosion-resistant technology, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems of inability to withstand tension and corrosion resistance of cables, inability to improve the service life of cables, and inability to better protect cables, etc. , to achieve the effect of improving wear resistance, safe and convenient use, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

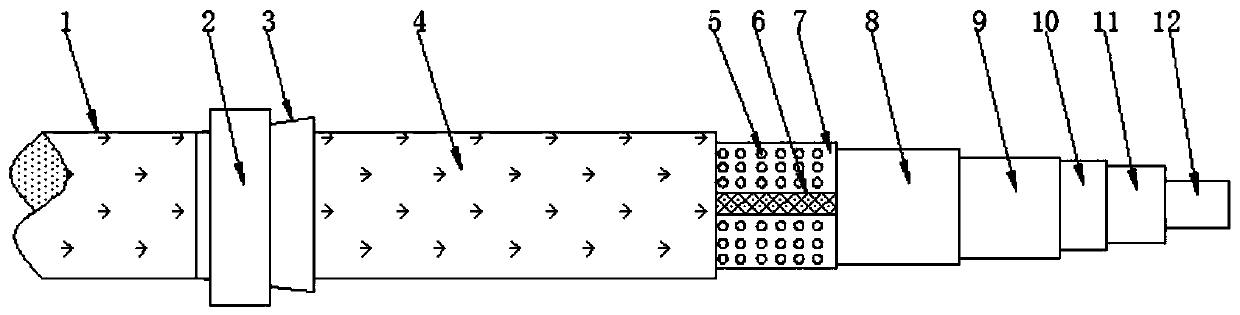

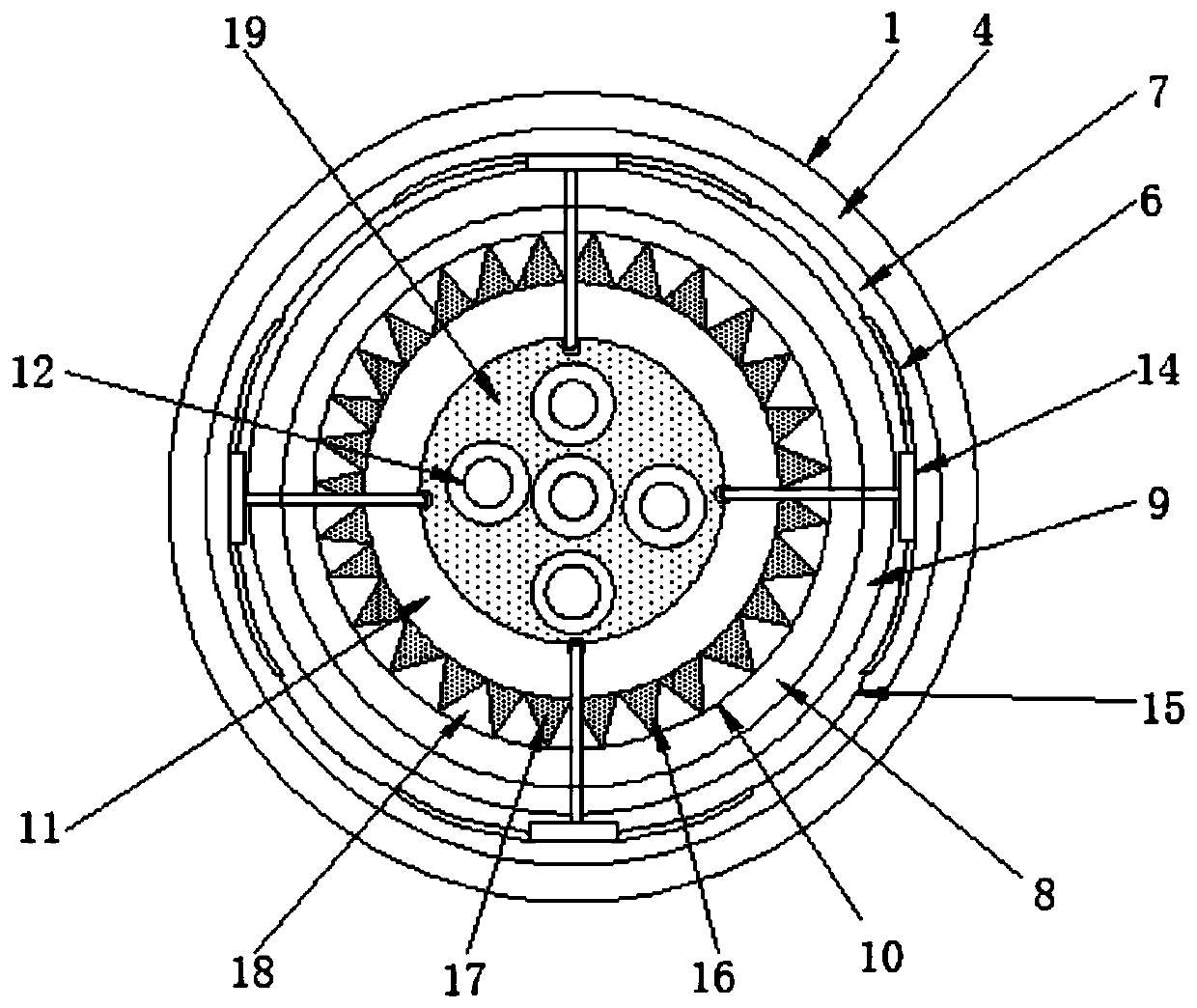

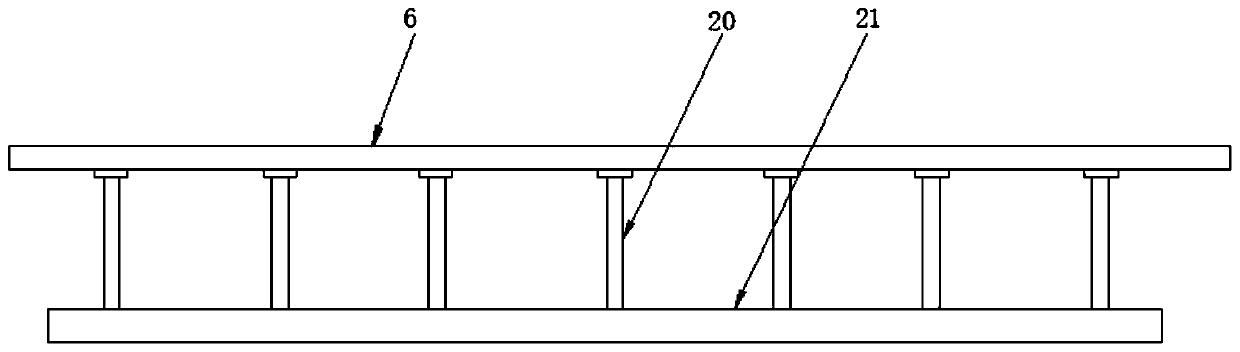

[0024] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a corrosion-resistant insulated overhead cable, including a cable body 1, a compression ring 2, a stretch section 3, an outer protective layer 4, burrs 5, a steel wire mesh 6, and an armor layer 7 , wear-resistant layer 8, flame-retardant water-proof layer 9, water-blocking wrapping layer 10, inner lining layer 11, conductor core 12, connecting body 14, semi-conductive shielding layer 15, shock-absorbing sheet 16, anti-corrosion lubricating grease layer 17, Gap 18, filled with desiccant 19, connecting wire 20, conductor wire 21 and installation groove 28, the outside of the cable body 1 is wrapped with an outer protection layer 4, the outside of the outer protection layer 4 is covered with a tensile section 3, and the outer protection layer 4 An armor layer 7 is arranged on the inner side of the stretching section 3, and a compression ring 2 is set on the outside of the stretchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com