Diaphragm integrated punching method

A film and die-cutting technology, which is applied in the optical field, can solve the problems of low efficiency of manual lamination assembly, poor lamination accuracy, and poor lamination, so as to reduce one tearing film and one lamination action, improve yield, The effect of improving the fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

[0027] Aiming at the backlight production with small production volume and the need to use artificial film sticking, in order to improve production efficiency and improve lamination accuracy, the present invention provides a film-integrated die-cutting method, which includes the following steps:

[0028] A punching method for an integrated diaphragm, comprising the following steps:

[0029] S1: Composite protective film and bottom mold on both sides of the diffuser;

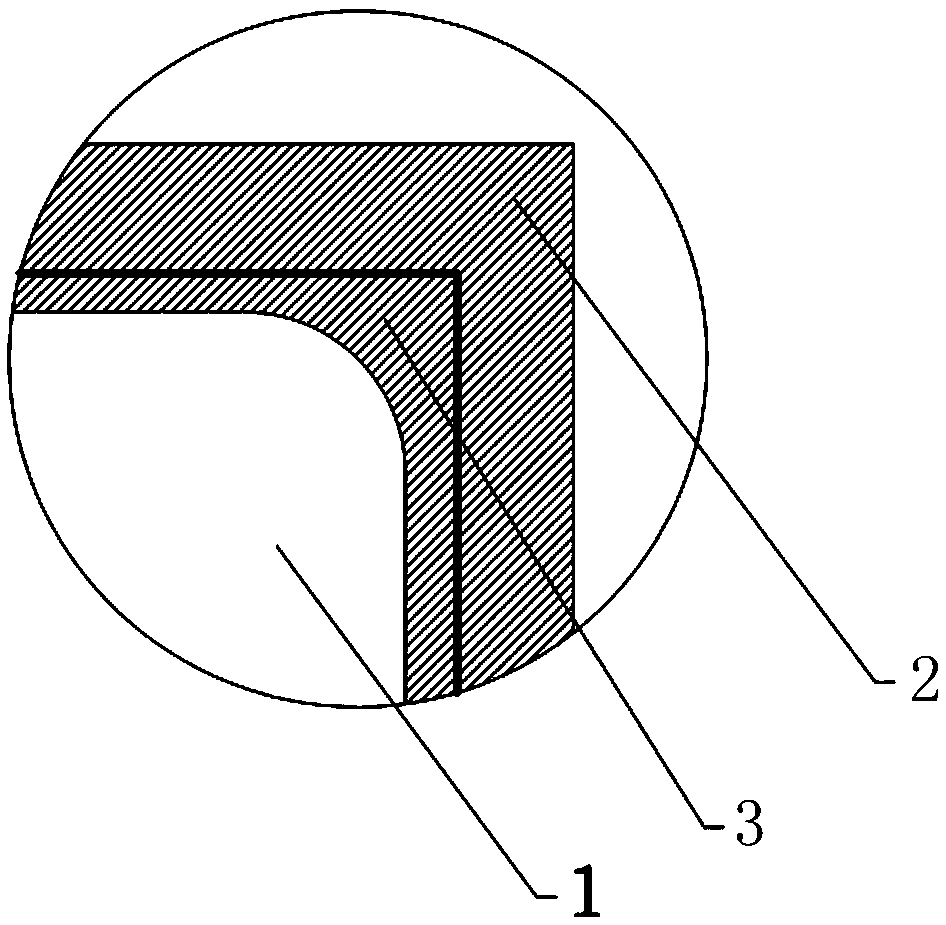

[0030] S2: see image 3 , use the first knife die to perform the first die-cutting and waste discharge from the protective film to the diffusion sheet; specifically, during the first die-cutting, the contour B is die-cut on the protective film, and the contour C is die-cut on the diffusion sheet , to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com