Hydraulic Synchronization Valve

A hydraulic synchronization, solenoid valve technology, applied in the direction of fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problem of increasing the burden and instability of the hydraulic system, high requirements on the strength of the hydraulic system, and reducing the stability of the hydraulic system. and other issues, to achieve the effect of improving the applicable scope, low cost and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

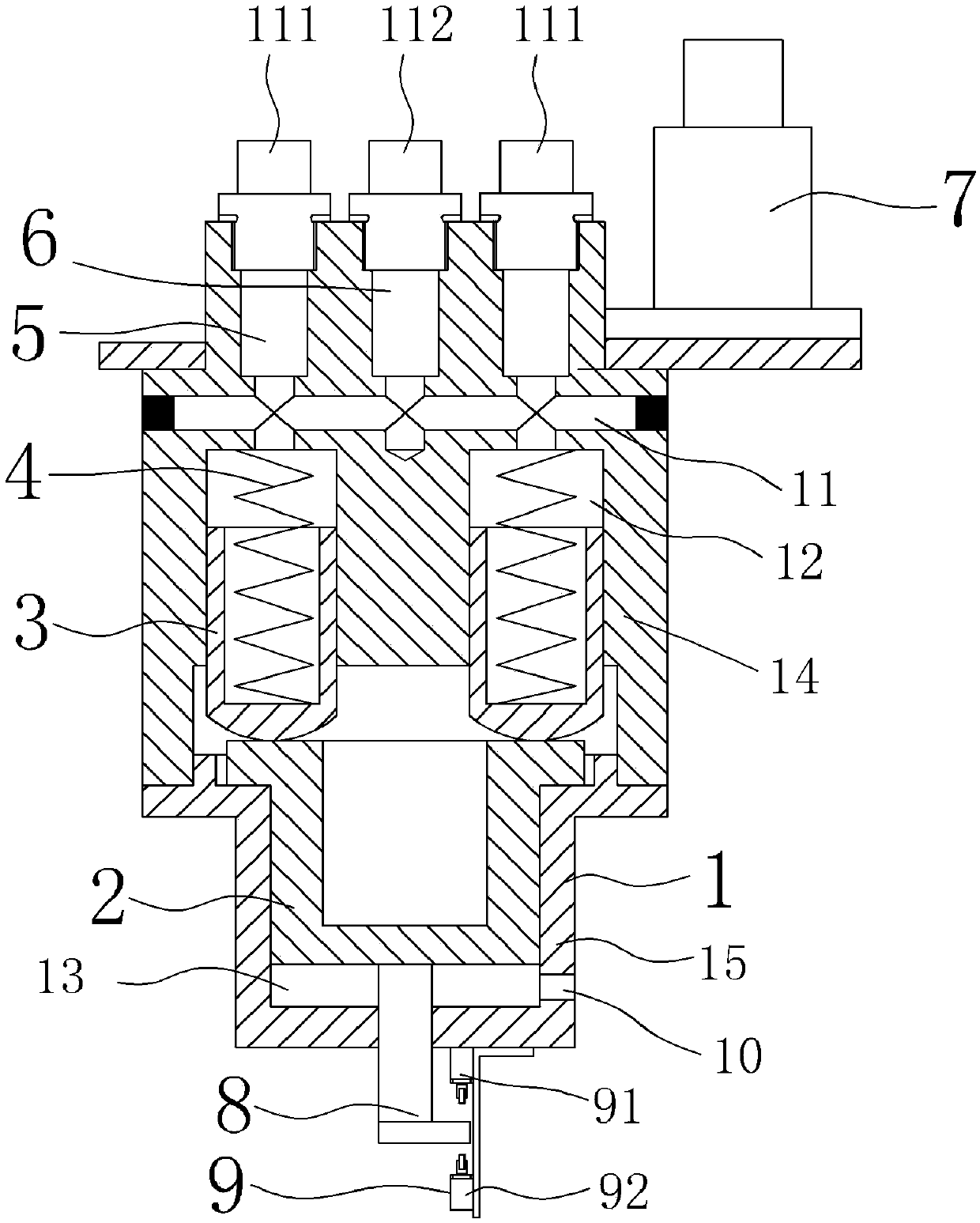

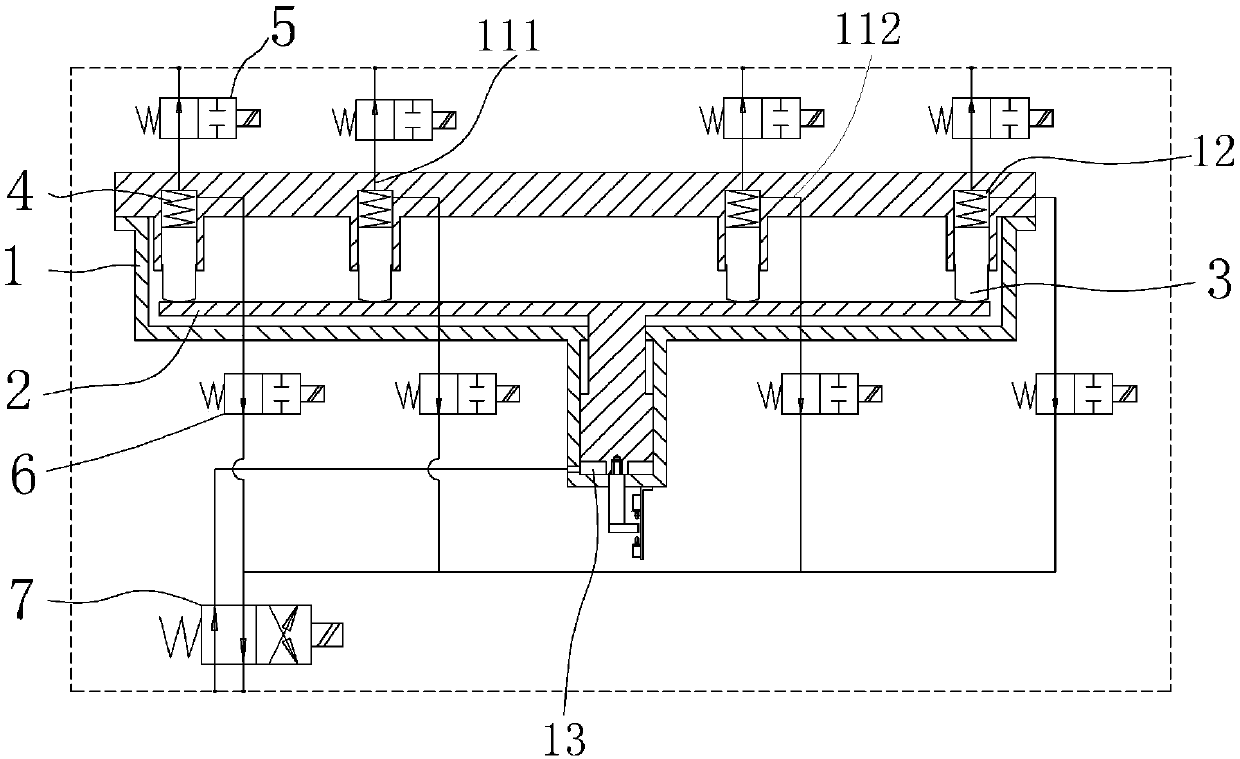

[0016] refer to figure 1 and figure 2 , The hydraulic synchronous valve of the present invention includes a cylinder 1, a main plunger 2, a sub-plunger 3, a spring 4, a first solenoid valve 5, a second solenoid valve 6, a push rod 8 and an induction switch 9.

[0017] The cylinder block 1 includes a cylinder body 14 and a cylinder head 15, the cylinder body 14 and the cylinder head 15 are connected by bolts, the cylinder body 14 is provided with an oil passage 11, and the oil passage 11 includes a working oil passage 111 and an oil return passage 112.

[0018] The size of the main plunger 2 matches the cylinder head 15, and the main plunger 2 is embedded in the cylinder head 15, so that the main plunger 2 and the cylinder head 15 enclose a second cavity 13, and the cylinder head 15 is provided with an oil port 10 , the oil port 10 communicates with the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com