Double-shell symmetric radially-split multi-stage centrifugal pump with first-stage double-suction structure

A symmetrical, double-shell technology, applied in the field of centrifugal pumps, can solve problems such as potential safety hazards, increase the complexity of centrifugal pumps, and balance drum disc wear, so as to prevent cavitation, reasonable and reliable structure, and achieve self-balancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

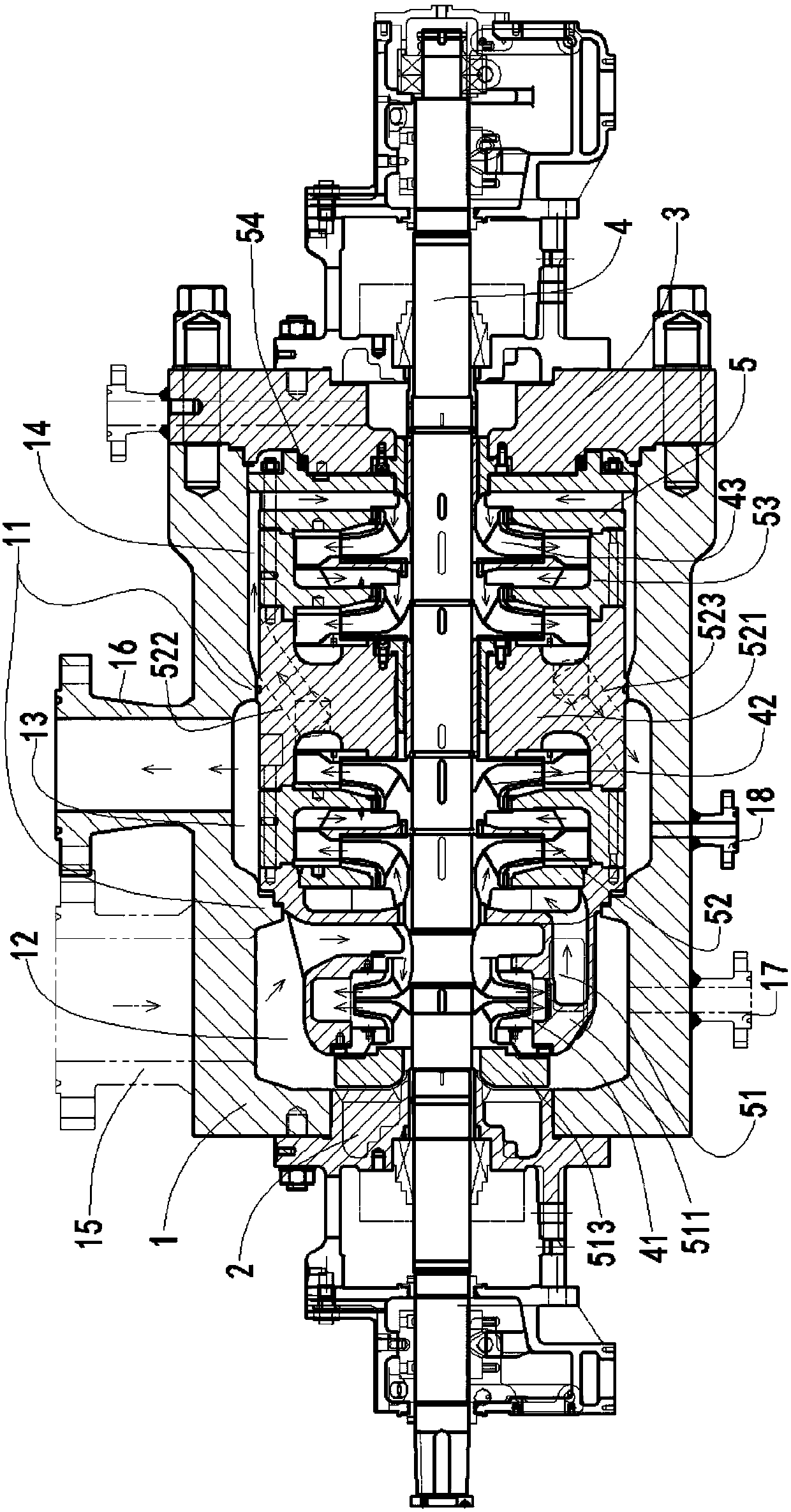

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

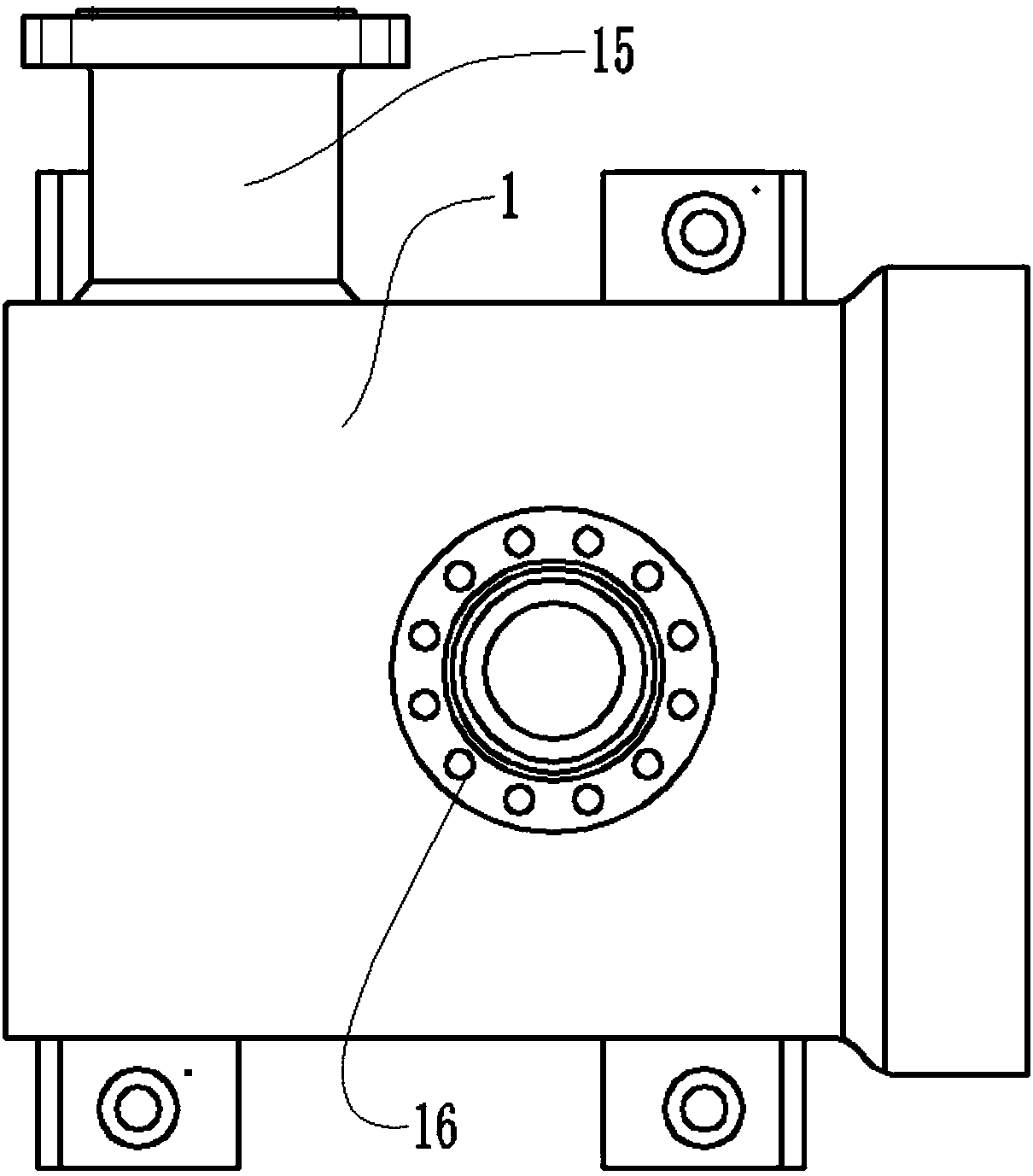

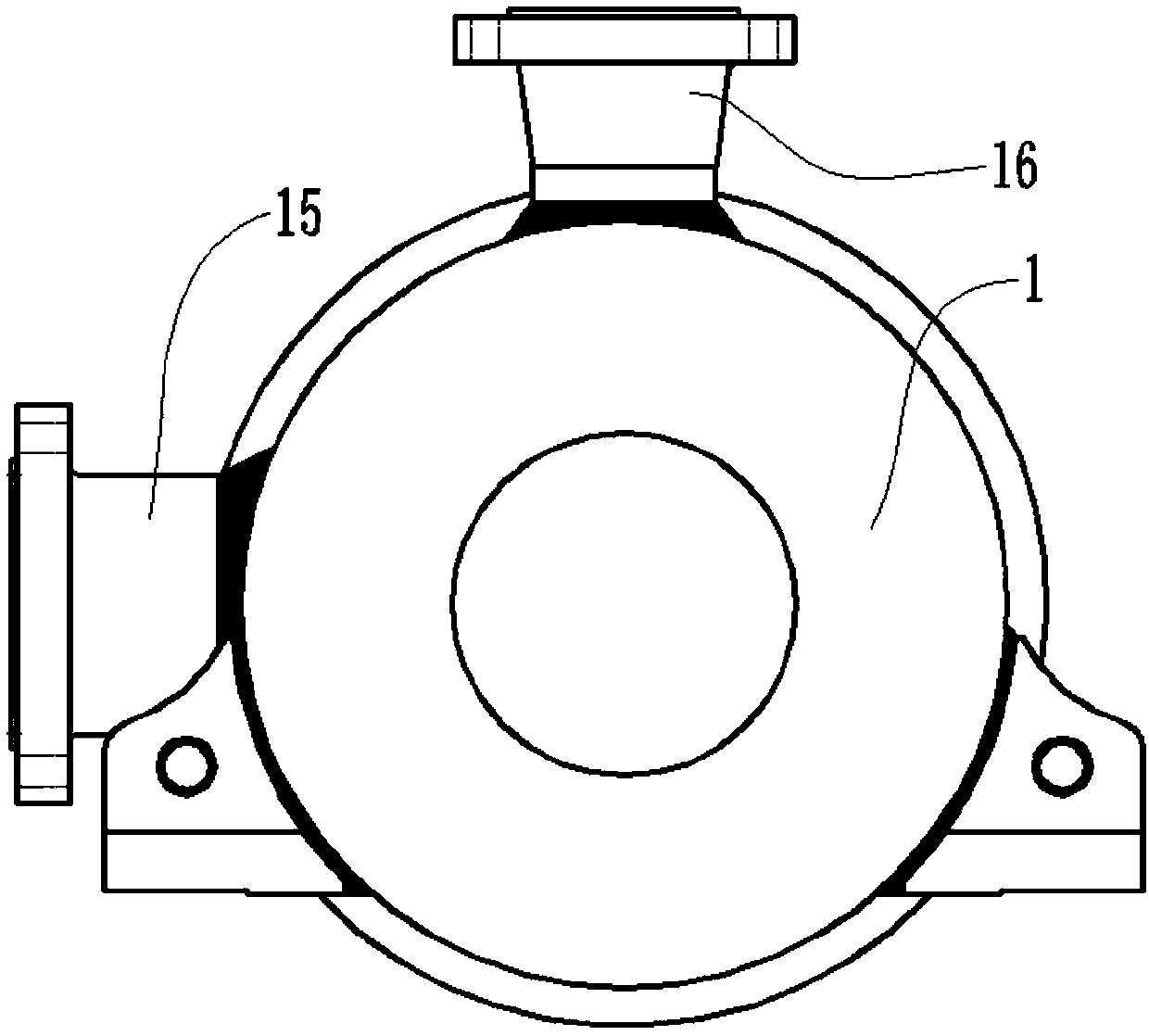

[0026] Such as figure 1 As shown in the embodiment, the first-stage double-suction structure double-casing symmetrical radially split multi-stage centrifugal pump includes an outer cylinder 1, the outer cylinder 1 is a cylindrical shape placed horizontally, and the outer cylinder 1 1. A horizontal installation cavity is processed inside. The left and right ends of the outer cylinder 1 are respectively equipped with a suction side stuffing box 2 and a pump cover 3 through a sealing structure. The middle of the outer cylinder 1 is coaxially equipped with a central shaft 4 , the two ends of the central shaft 4 protrude from the middle of the suction side stuffing box body 2 and the pump cover 3 respectively, and the central shaft 4 can be coaxial with the suction side stuffing box body 2 and the pump cover 3 Rotary assembly; the pump cover 3 is also installed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com