Railway engineering machine hybrid power source switching system

A technology of power source switching and railway engineering, applied in motor vehicles, railway vehicles, traction driven by engines, etc., to achieve the effects of short switching time, improved work efficiency, and short power-off time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

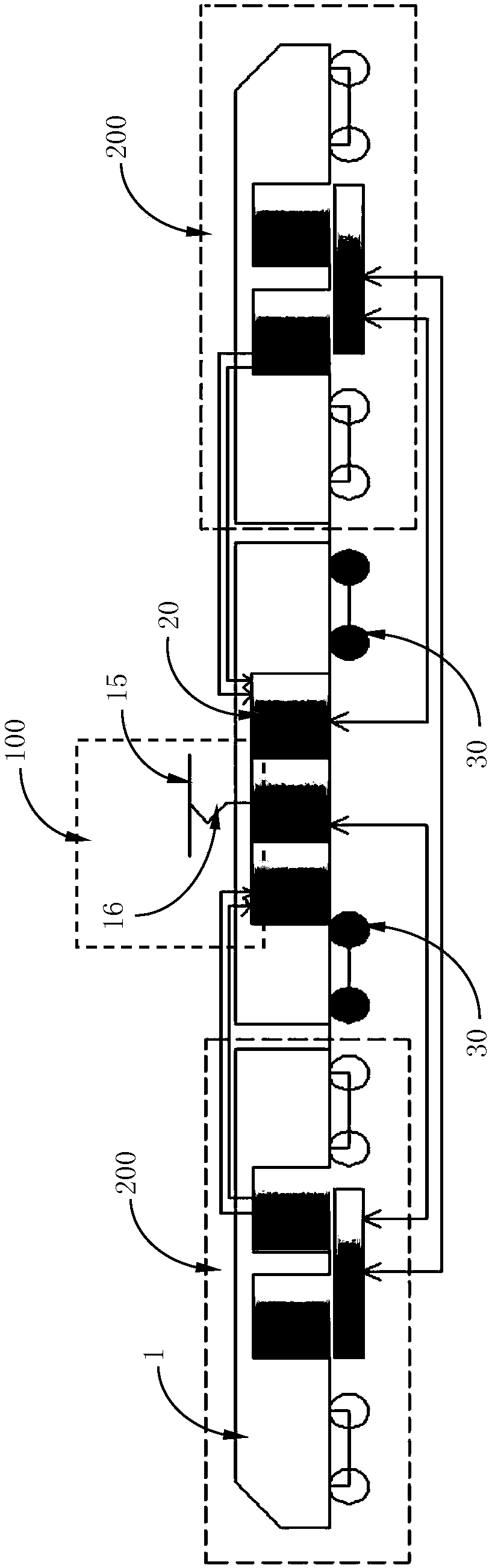

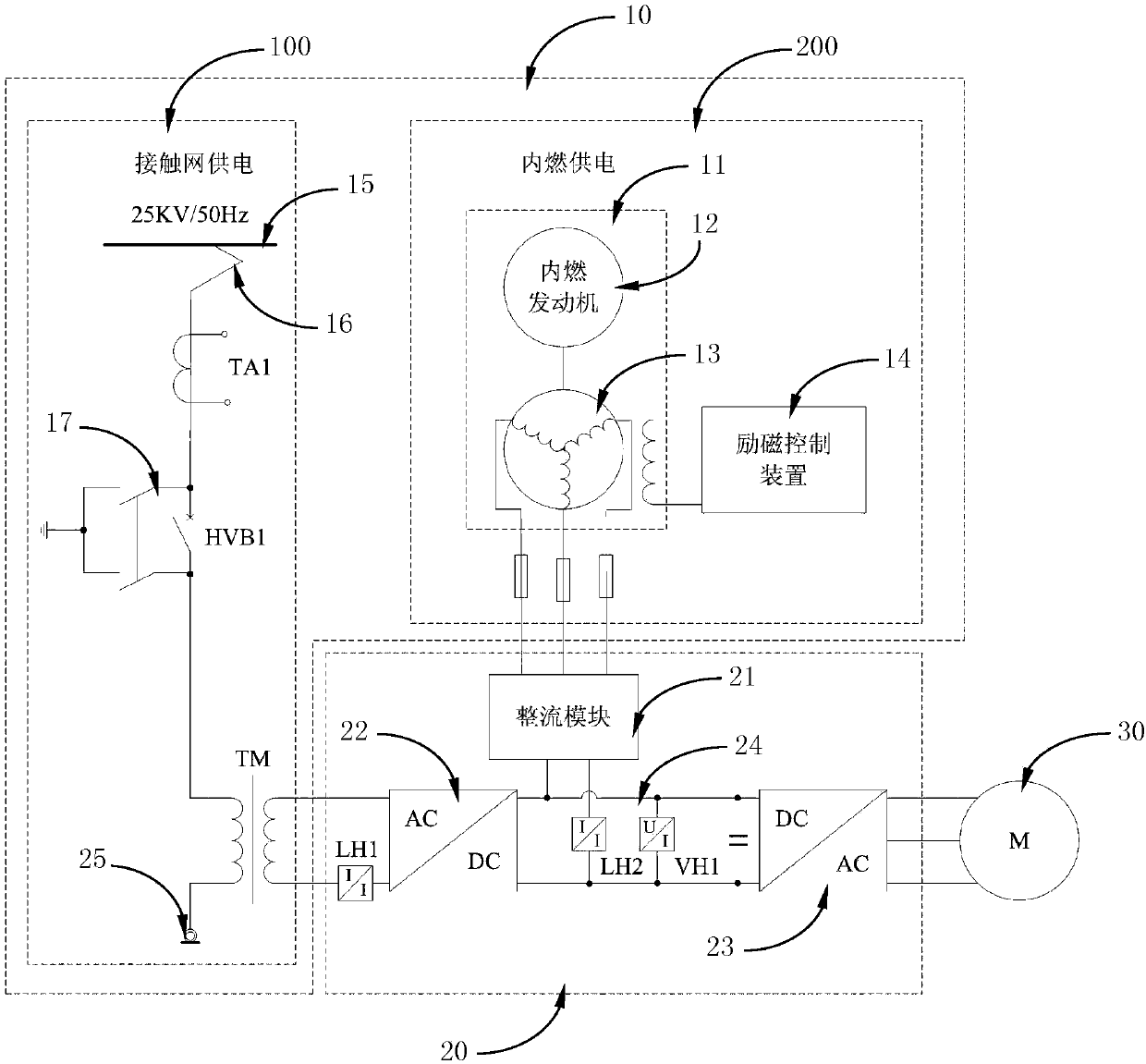

[0039] as attached figure 1 As shown, a specific embodiment of a railway engineering machinery hybrid power source switching system includes: a hybrid power source 10, and a converter 20 connected to the hybrid power source 10, and the hybrid power source 10 is a traction motor through the converter 20 30 power supply. The hybrid power source 10 further includes an catenary power supply module 100 and an internal combustion power supply module 200 , and the electric energy from the catenary power supply module 100 or the internal combustion power supply module 200 is transformed and processed by the converter 20 and converted into electric energy required by the traction motor 30 . The railway construction machinery hybrid power source switching system described in this embodiment adopts the electric / internal combustion hybrid power main circuit, which includes two modes of catenary power supply and internal combustion generator set power supply, which take power from the cate...

Embodiment 2

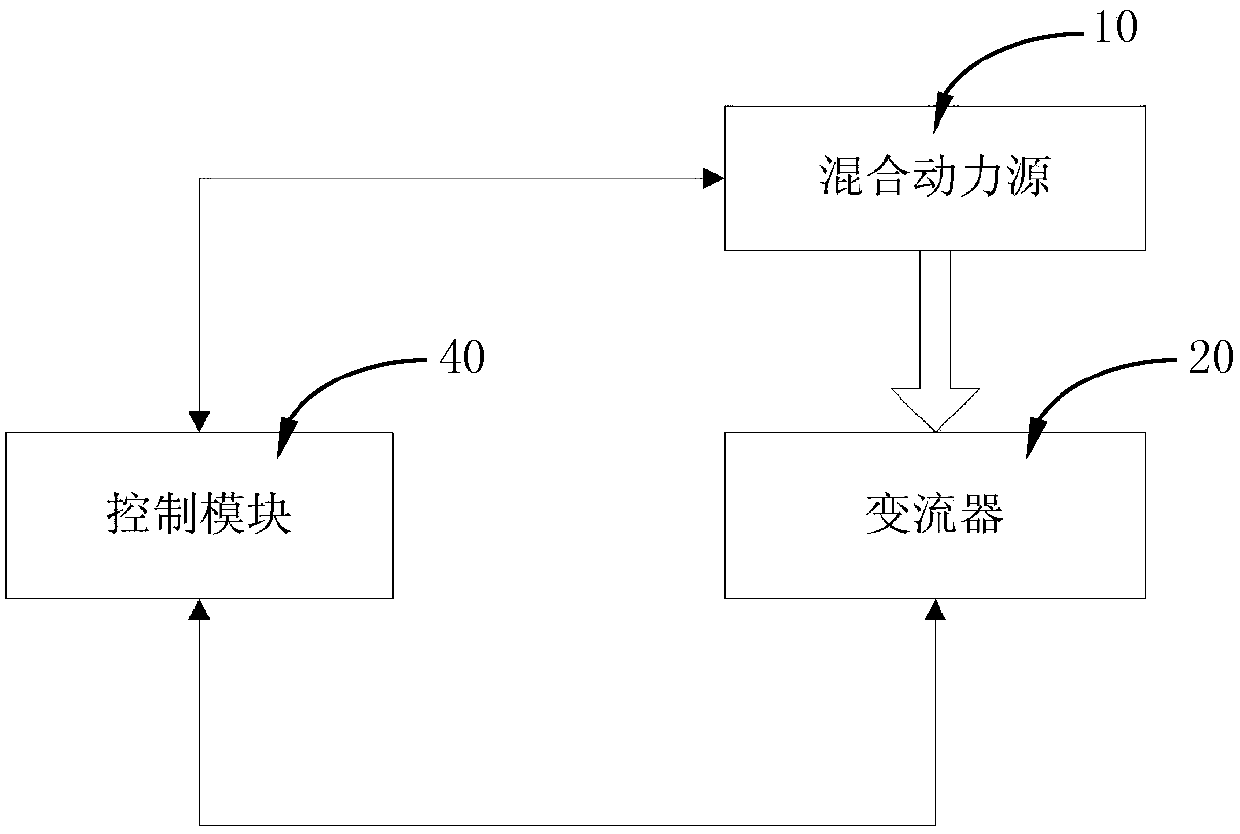

[0047] as attached Figure 4 As shown, a control method for the hybrid power source switching system of railway engineering machinery described in Embodiment 1, the hybrid power source 10 includes an catenary power supply module 100 and an internal combustion power supply module 200, from the catenary power supply module 100 or the internal combustion power supply module 200 The electric energy is transformed and processed by the converter 20 and then converted into electric energy required by the traction motor 30 . The control method includes the following steps:

[0048] A) When the electrical connection between the railway engineering machinery 1 and the catenary 15 is turned on, and the catenary 15 continues to supply power, the traction motor 30 is powered by the catenary power supply module 100;

[0049] B) When the electrical connection between the railway engineering machinery 1 and the catenary 15 is disconnected, or the catenary 15 cannot continue to supply power, ...

Embodiment 3

[0065] A control method for the hybrid power source switching system of railway engineering machinery described in Embodiment 1. The hybrid power source 10 includes a catenary power supply module 100 and an internal combustion power supply module 200, and the electric energy from the catenary power supply module 100 or the internal combustion power supply module 200 is passed through The converter 20 converts and processes the electrical energy required by the traction motor 30 . The control method includes the following steps:

[0066] A) When the electrical connection between the railway engineering machinery 1 and the catenary 15 is turned on, and the catenary 15 continues to supply power, the traction motor 30 is powered by the catenary power supply module 100;

[0067] B) When the electrical connection between the railway engineering machinery 1 and the catenary 15 is disconnected, or the catenary 15 cannot continue to supply power, the internal combustion power supply mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com