Air conditioner shell stamping bed with punch automatic conversion function

An air-conditioning shell and automatic conversion technology, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of long processing time, low processing efficiency, and long replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

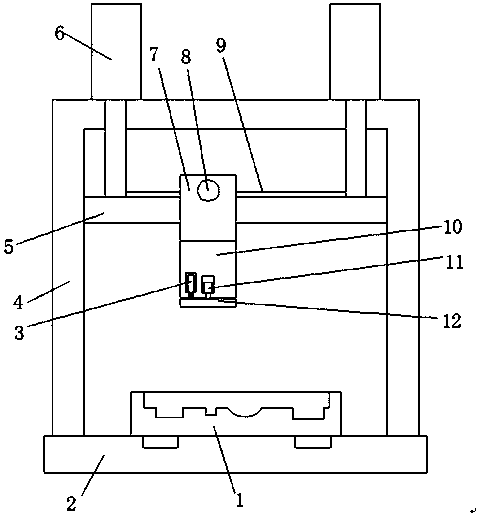

[0018] Embodiment: when punching, the air-conditioning shell is installed on the lower mold base 1;

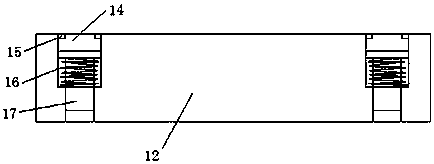

[0019] The first cylinder 3 drives the movable block to move downward, and drives one of the stamping heads 17 to compress the spring 16 to stretch out;

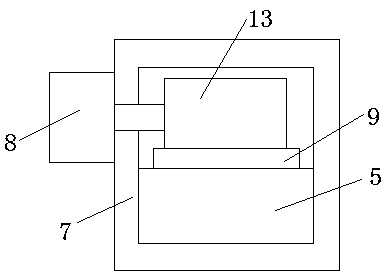

[0020] The third cylinder drives the lower mold base 1 to move on the base 2, the first motor 8 drives the gear 13 to move, the gear 13 meshes with the rack 9, drives the movable frame 7 to move on the cross bar 5, and the first cylinder 6 drives the cross bar 5 Sliding inside the fixed frame 4, stamping the air conditioner casing on the lower mold base 1;

[0021] After a punch has been punched, the first cylinder 3 drives the movable block to move upwards, a punch head 17 resets under the drive of the spring 16, and the second motor 11 drives the punching seat 12 to rotate, so that the axis of the first cylinder 3 is aligned with the other punching head. The axes of the heads 17 are the same, the first cylinder 3 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com