Phase change energy storage soaking smoke-free wok

A technology of phase change energy storage and frying pans, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc. It can solve the problems of large human factors such as time and degree, so as to ensure heat storage capacity, high performance of weight, and improve the overall performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

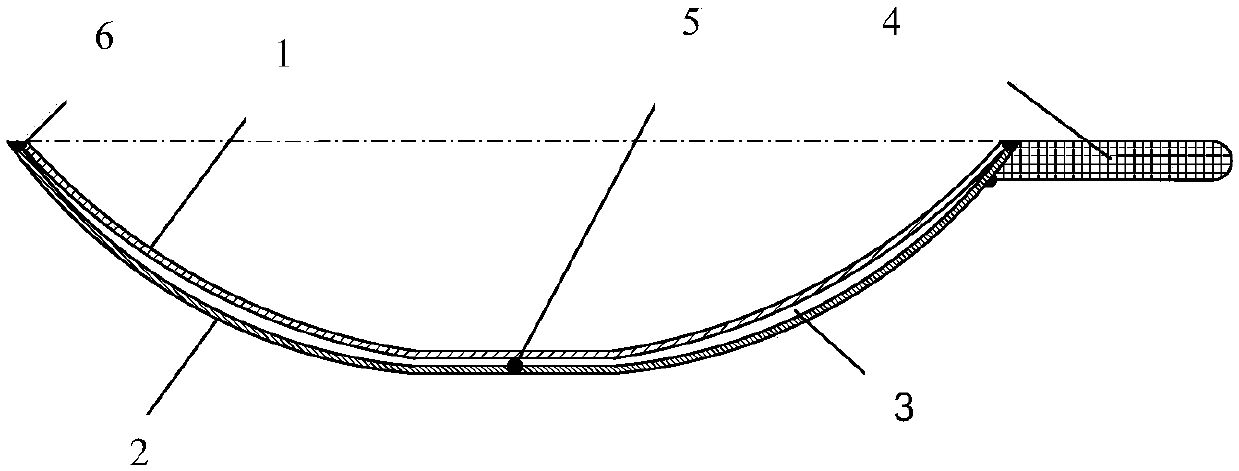

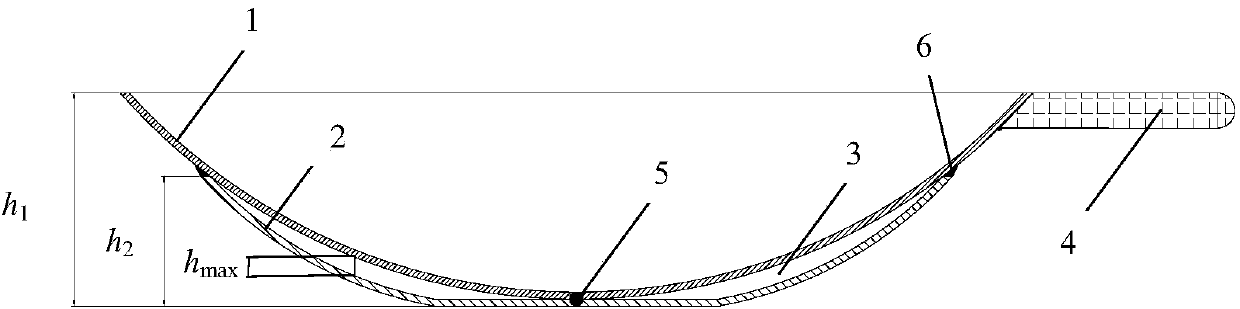

[0056] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0057] The phase-change energy storage homogeneous smokeless frying pan of the present invention includes a pot body and a handle 4, the pot body includes a pot inner wall 1, a pot outer wall 2 and an interlayer 3, and the interlayer 3 is between the pot inner wall 1 and the pot outer wall 2 A sealed structure is formed, and the interlayer 3 is filled with molten salt, fine sand, or a mixture of fine sand and molten salt. The handle 4 is arranged on the outer wall 2 of the pot, and the handle 4 is integrally formed with the outer wall 2 of the pot or the handle 4 is welded on the outer wall 2 of the pot.

[0058] After the interlayer 3 is filled with molten salt, fine sand or a mixture of the two, the interlayer 3 can be directly sealed, or before the interlayer 3 is sealed, the air in the interlayer 3 is taken out to keep the interlayer 3 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com