Low-speed rotating electric heating technology for steam-turbine generator rotor in dynamic balance test

A technology for dynamic balancing of turbogenerators and rotors, applied in static/dynamic balance testing, testing of machine/structural components, measuring devices, etc., can solve the problems of thermal aging, inapplicability of dynamic balance test rooms, high test costs, etc. problem, to achieve the effect of solving a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

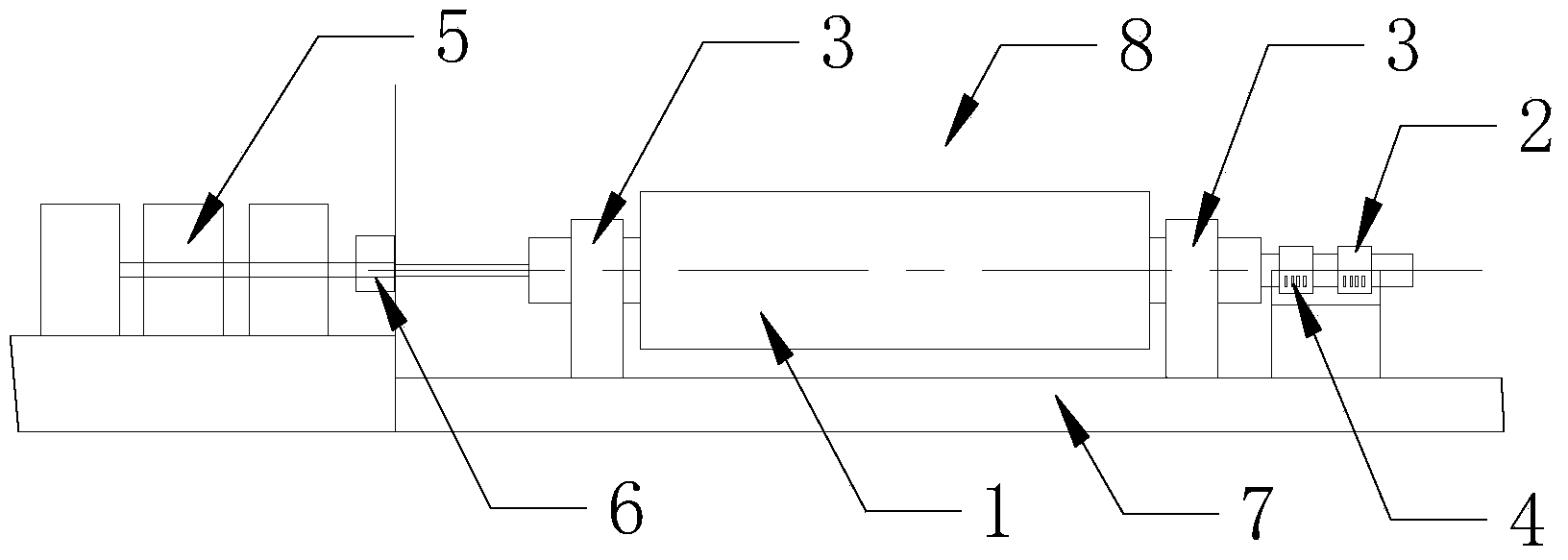

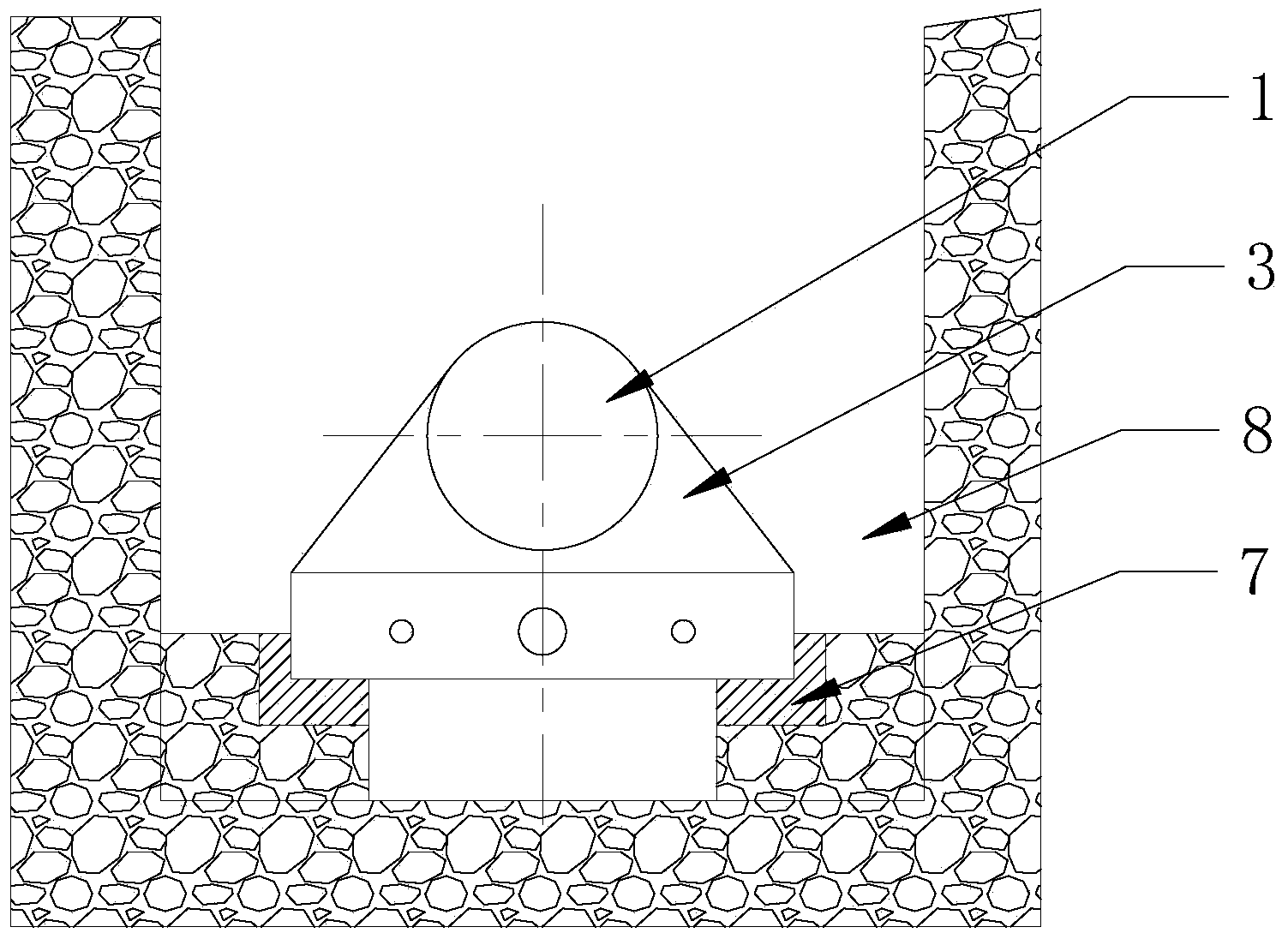

[0041] A low-speed rotating electric heating process for a turbogenerator rotor 1 dynamic balance test. Its process steps are as follows:

[0042] 1) When the turbogenerator rotor 1 is undergoing a dynamic balance test in the manufacturing plant, a low-speed rotating electric heating process is used to complete the thermal aging test of the rotor 1;

[0043] 2) When the turbine generator rotor 1 rotates electrically at low speed, the test brush holder 4 is used to provide the excitation current for heating to the rotor collector ring 2;

[0044] 3) When the turbine generator rotor 1 rotates at a low speed and is electrically heated, the rotor 1 rotates at the speed of the barring machine 6:

[0045] 4) When the rotor 1 of the turbogenerator rotates at a low speed and is electrically heated, for a drive system with a lower minimum speed of the drive motor 5, the rotor 1 can also drive the motor 5 to rotate at a minimum speed;

[0046] 5) When the turbine generator rotor 1 rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com