Five-axis numerical control machine tool planar processing process ball-end cutter and workpiece contact area semi-analytic modeling method

A technology of ball-end milling cutter and contact area, which is applied in the field of five-axis CNC machine tool processing, can solve the problem of semi-analytical modeling without ball-end milling cutter and workpiece contact area, and achieve high engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0026] A semi-analytical modeling method for the contact area between the ball end milling cutter and the workpiece in the plane machining process of the five-axis CNC machine tool, including the following steps:

[0027] Step 1: Carry out tool path planning and set NC machining parameters.

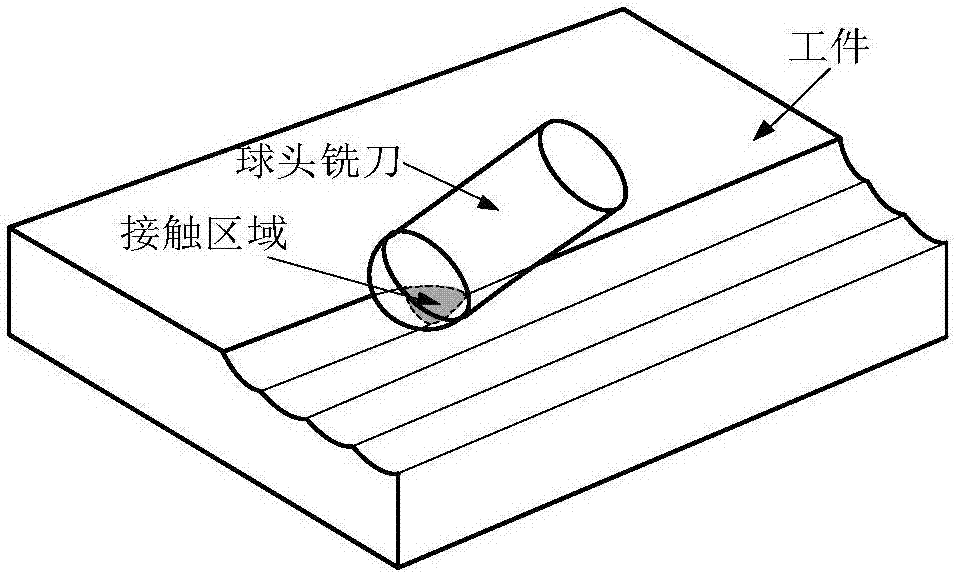

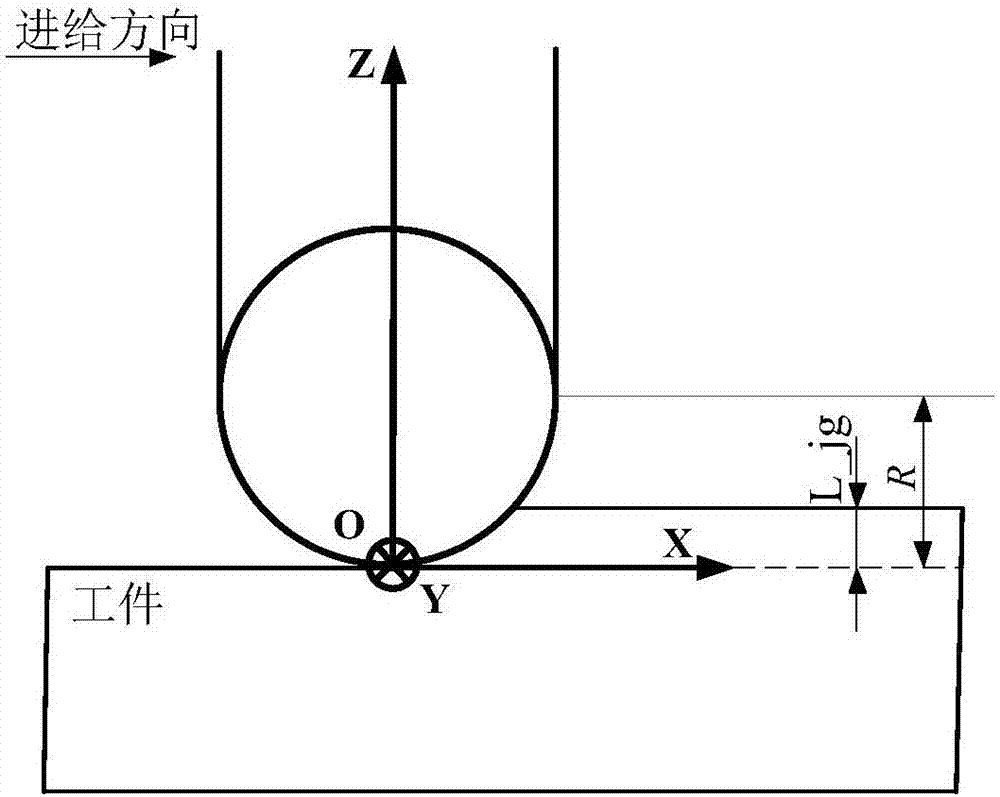

[0028] The radius of the ball head of the ball end milling cutter is R, and the ball end milling cutter is used for plane milling on a five-axis CNC machine tool. The inclination angle is β degrees, where α and β are both set to positive values.

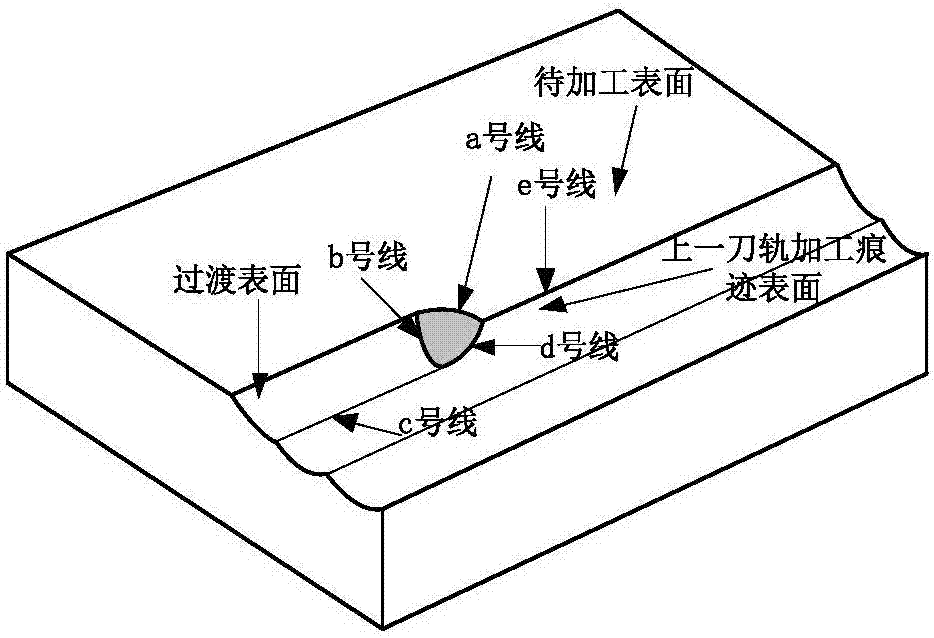

[0029] Step 2: Determine the composition of the contact area boundary between the ball end mill and the workpiece when the forward inclination angle is α degree and the side inclination angle is β degree, and transform the problem of solving the boundary of the contact area into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com