Circuit structure and working method of mechanical-electric integrated device

A technology of circuit structure and working method, applied in the direction of electrical program control, program control in sequence/logic controller, etc., can solve the problems of mixed wiring, difficult long-distance wiring, troublesome operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

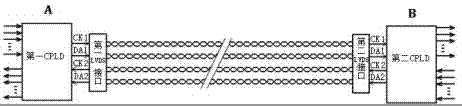

[0021] refer to figure 1 ,like figure 1 The circuit structure of a kind of mechanical and electrical integration equipment shown, comprises first CPLD, second CPLD, first low-voltage differential signal LVDS interface, second low-voltage differential signal LVDS interface, clock and data line; Said first CPLD electrical property connected to the first low-voltage differential signal LVDS interface; the second CPLD is electrically connected to the second low-voltage differential signal LVDS interface; the first low-voltage differential signal LVDS interface and the second low-voltage differential signal LVDS interface are electrically connected through the clock line and the data line connect.

Embodiment 2

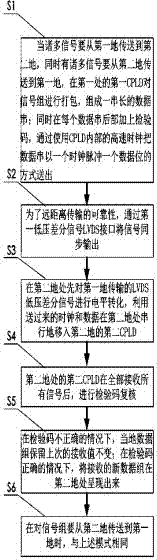

[0023] refer to figure 2 ,like figure 2 The working method of the circuit structure of a kind of mechatronics equipment shown, comprises the following steps:

[0024] S1, when many signals are to be transmitted from the first ground to the second ground, and many signals are to be transmitted from the second ground to the first ground at the same time, the first CPLD at the first place packs the signal groups to form a long string Data string; at the same time, add a check code at the end of each data string, and send the data string in the form of a clock pulse and a data bit by using the high-speed clock inside the CPLD;

[0025] S2, for the reliability of long-distance transmission, synchronously output the signal through the first low-voltage differential signal LVDS interface;

[0026] S3, at the second location, first perform level conversion on the LVDS low-voltage differential signal transmitted at the first location, and use the clock and data sent to move seriall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com