Photoelectric conversion module for realizing optical power monitoring and manufacturing method thereof

A photoelectric conversion module, optical power monitoring technology, applied in the coupling of optical waveguides, electrical components, electromagnetic transmitters, etc., can solve the problems of reducing the reliability of the optical path, many optical path components and optical surfaces, and long optical path, etc. Optical path reliability, ensuring performance stability, and increasing the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

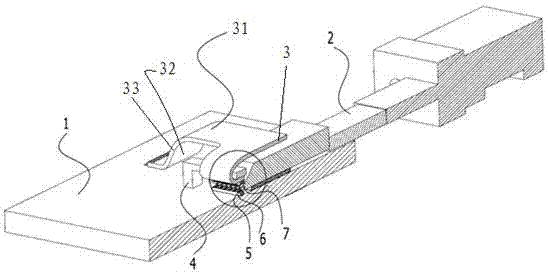

[0026] Such as figure 1 As shown, the photoelectric conversion module proposed by this application to realize optical power monitoring, especially the parallel photoelectric conversion module, includes PCB board 1, optical fiber array assembly 2, flexible board 3, metal bracket 4, laser 5 and detector 7; laser 5 Mount on PCB board 1.

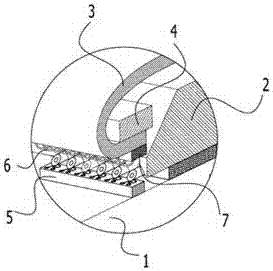

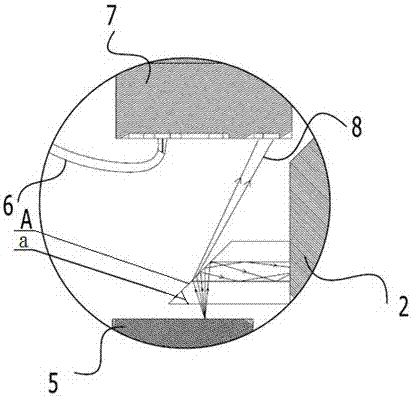

[0027] Specifically, such as figure 2 As shown, the detector 7 is mounted on the first surface 31 of the flexible board 3; the part corresponding to the detector 7 on the second surface 32 of the flexible board 3 opposite to the first surface 31 is connected to the lower end surface of the metal bracket 4; The bracket 4 is welded on the PCB board 1, and the detector 7 is placed relative to the laser 5; as image 3 As shown, the end face A of each fiber of the fiber array assembly 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com