A construction method for dismantling thin shell dome of gas tank

A construction method and gas cabinet technology, applied in the direction of adjustable capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems affecting the health of operators, long preparation period, and high labor intensity. Achieve the effect of reasonable demolition construction technology, simple and applicable operation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

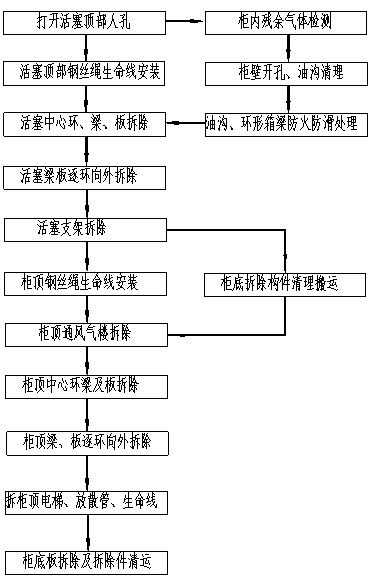

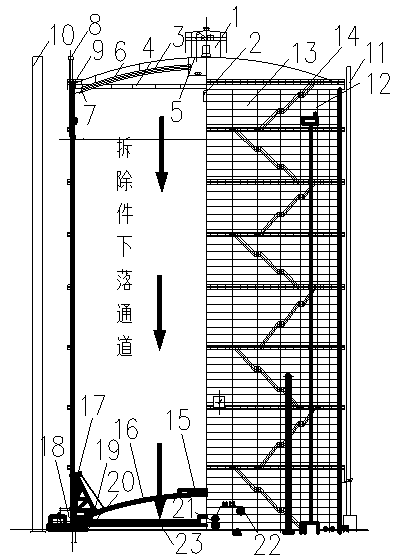

[0038] see now figure 1 , figure 1 It is a schematic diagram of dismantling a gas cabinet according to an embodiment of the present invention.

[0039] The demolition construction process for the thin shell dome of the gas cabinet of the present invention comprises the removal of the piston and the top of the cabinet, comprising the following steps:

[0040] a. Medium isolation, replacement inside the cabinet

[0041] The piston descends to the bottom of the gas tank, and the piston annular box beam is placed on the piston support; the valve of the gas tank inlet and outlet pipes has been closed, the gas in the gas tank has been exhausted, and the replacement is qualified.

[0042] Use a wrench to open all the manholes above and below the piston, and install a blower outside the opened manhole to promote air convection to accelerate replacement; use oxygen, carbon monoxide and hydrogen sulfide gas detectors to detect that the concentration of carbon monoxide is less than 30m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com