A Folding Straight Ladder for Demolition of Dry Gas Tank Wall Panels

A technology of straight climbing ladders and gas tanks, applied in the field of climbing ladders, can solve the problems of inconvenient circular horizontal movement of hydraulic lifts and inability to move the lift horizontally, and achieve the effects of material saving, reasonable dismantling process, and simple and applicable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

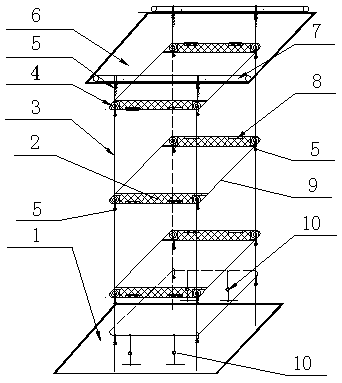

[0028] see now figure 1 , figure 1 It is a structural schematic diagram of a straight climbing ladder according to an embodiment of the present invention. As shown in the figure, the fixed unit at the top of the straight ladder is at the platform 1 of the upper corridor near the H-shaped steel column, and the 400*400mm ladder installation hole is gas-cut, and two seamless steel pipes 7 of Φ48*3.5mm are cross-armed on the platform. Wind knots at the end of each steel wire rope 3 of the ladder (a total of 4 Φ8mm steel wire ropes), clamp and fix it with two Y-8 steel wire rope clamps, seamless steel pipe 7 passes through the 3 knots of steel wire ropes, and the cross arm is on the corridor platform on the force.

[0029] The body of the folding straight climbing ladder is composed of steel wire rope 3, operation steps 2, hinge 8, flat washer 4 and wire rope clamp 5, etc.

[0030] The vertical force-bearing surface of the ladder is composed of four Φ8mm steel wire ropes 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com