Multi-mode clutch

A clutch and outer ring technology, applied in the field of clutches, can solve problems such as single working mode of roller clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

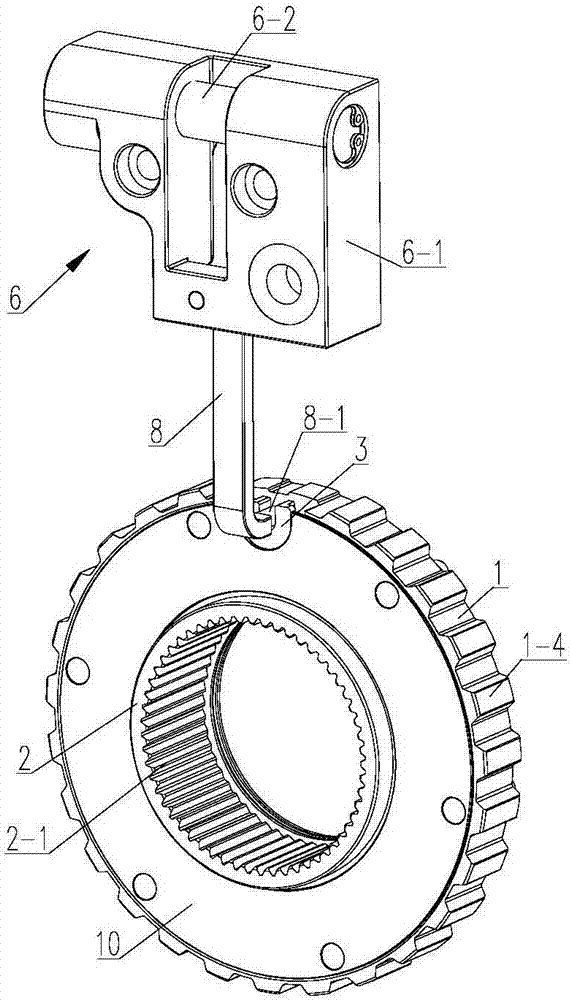

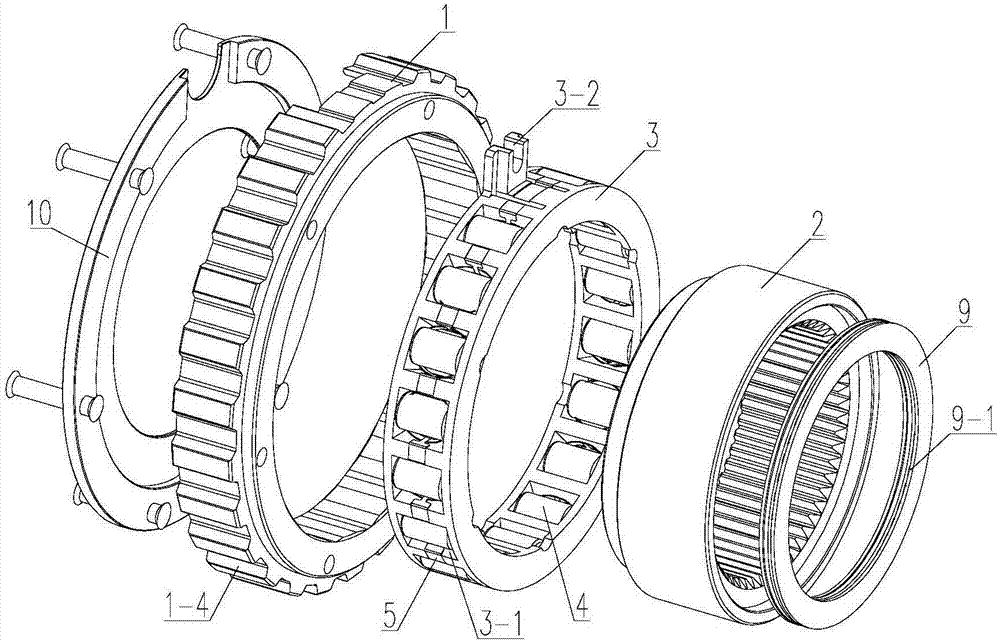

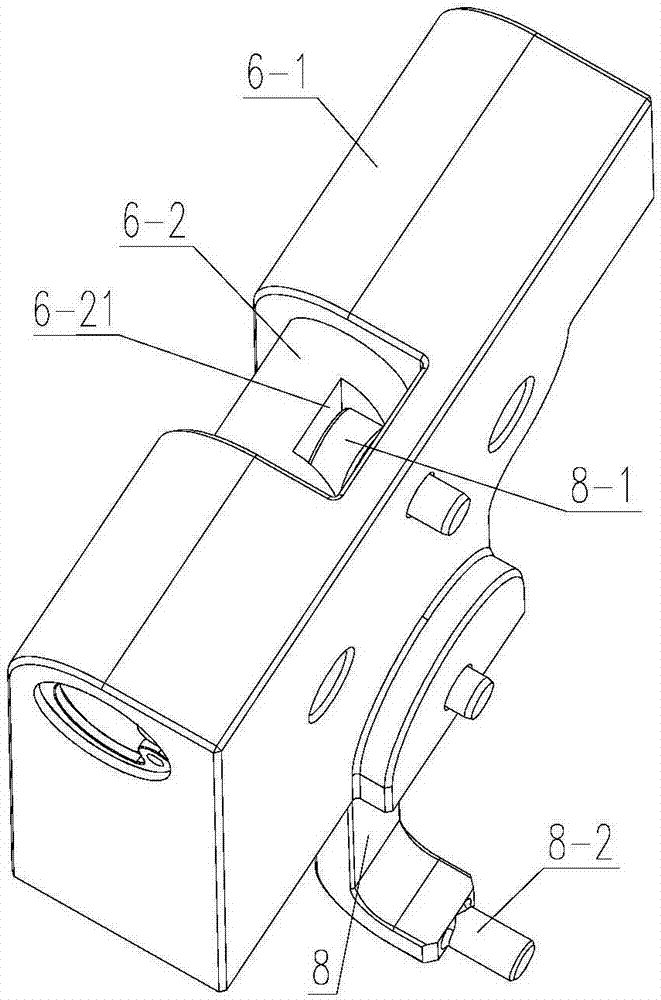

[0034] Such as Figure 1-9 As shown, a multi-mode clutch includes a clutch body and an actuator;

[0035] The clutch body includes an outer ring 1 and an inner ring 2 arranged coaxially, and a control ring 3 is arranged between the outer ring 1 and the inner ring 2. The outer peripheral surface of the control ring 3 runs through a number of windows 3-1 along its circumferential direction. 3-1 is equipped with a roller 4, and the inner ring wall of the outer ring 1 has a number of cavities 1-1 corresponding to the rollers 4;

[0036] The distance from the middle part of the cavity bottom 1-11 in the cavity 1-1 to the outer wall of the inner ring 2 is greater than the diameter of the roller 4, and the left side 1-12 of the cavity 1-1 is from the cavity bottom 1-11 to the left The side surface 1-12 gradually inclines toward the inner ring 2, and the right side 1-13 of the cavity 1-1 gradually inclines toward the inner ring 2 from the cavity bottom 1-11 to the right side 1-13;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com