A Construction Method of Surface-Controlled Blasting Excavation for Ultra-large and Widening Sections of Tunnels

A technology for controlling blasting and construction methods, which is applied to tunnels, earthwork drilling, mining equipment, etc., and can solve problems such as large impact on construction period, delay in work, and difficulty in effective control of widened sections, so as to reduce construction costs and simplify construction procedures , The effect of avoiding the risk of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

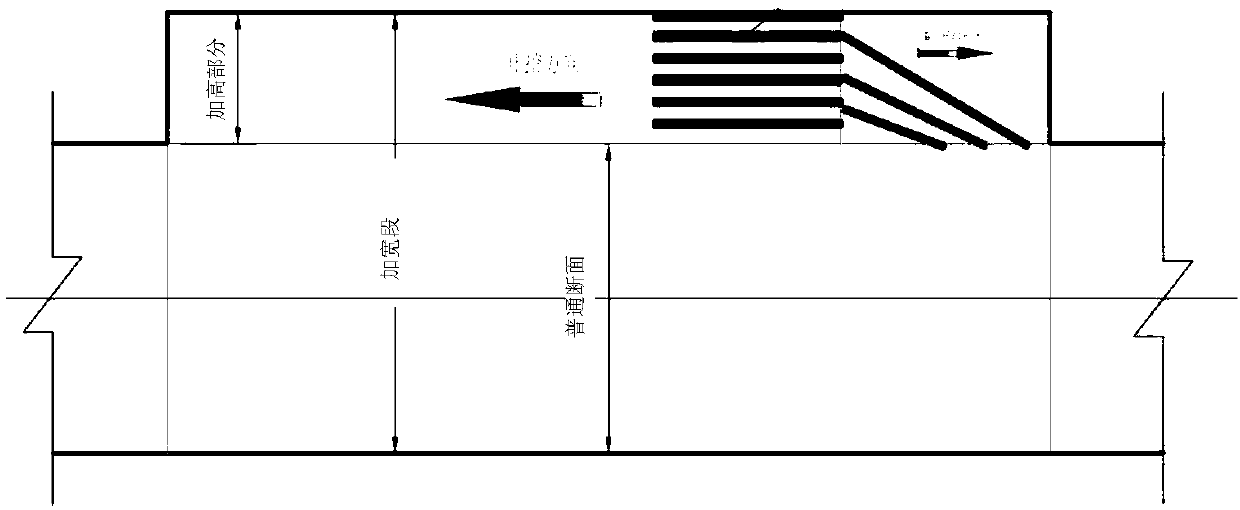

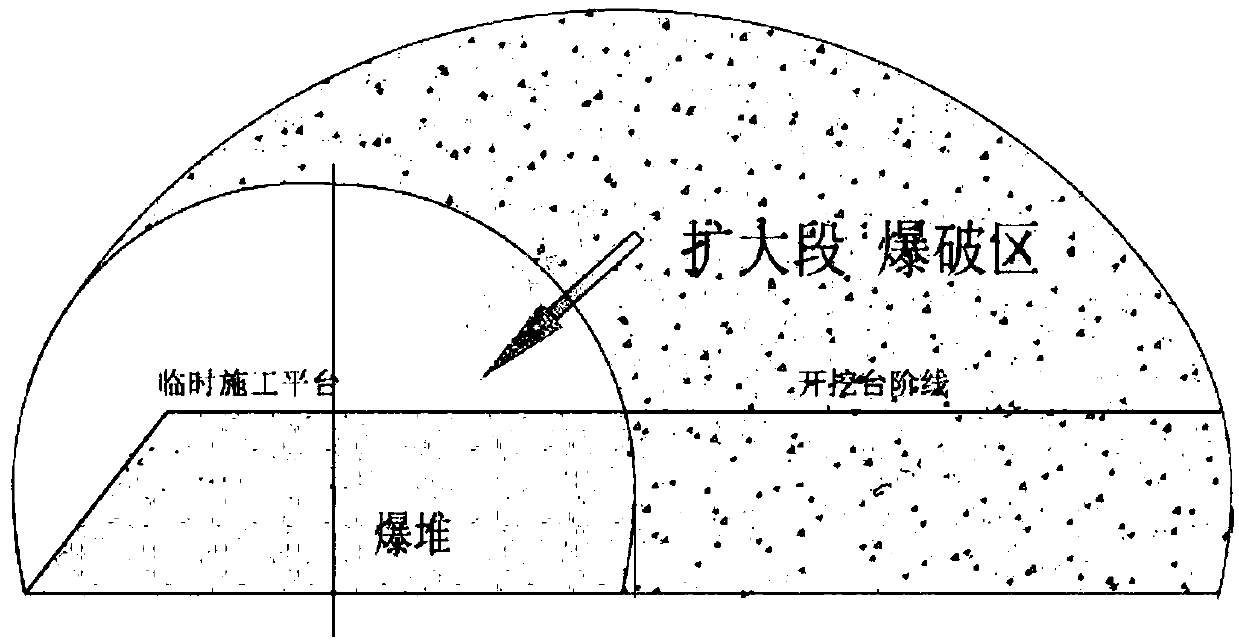

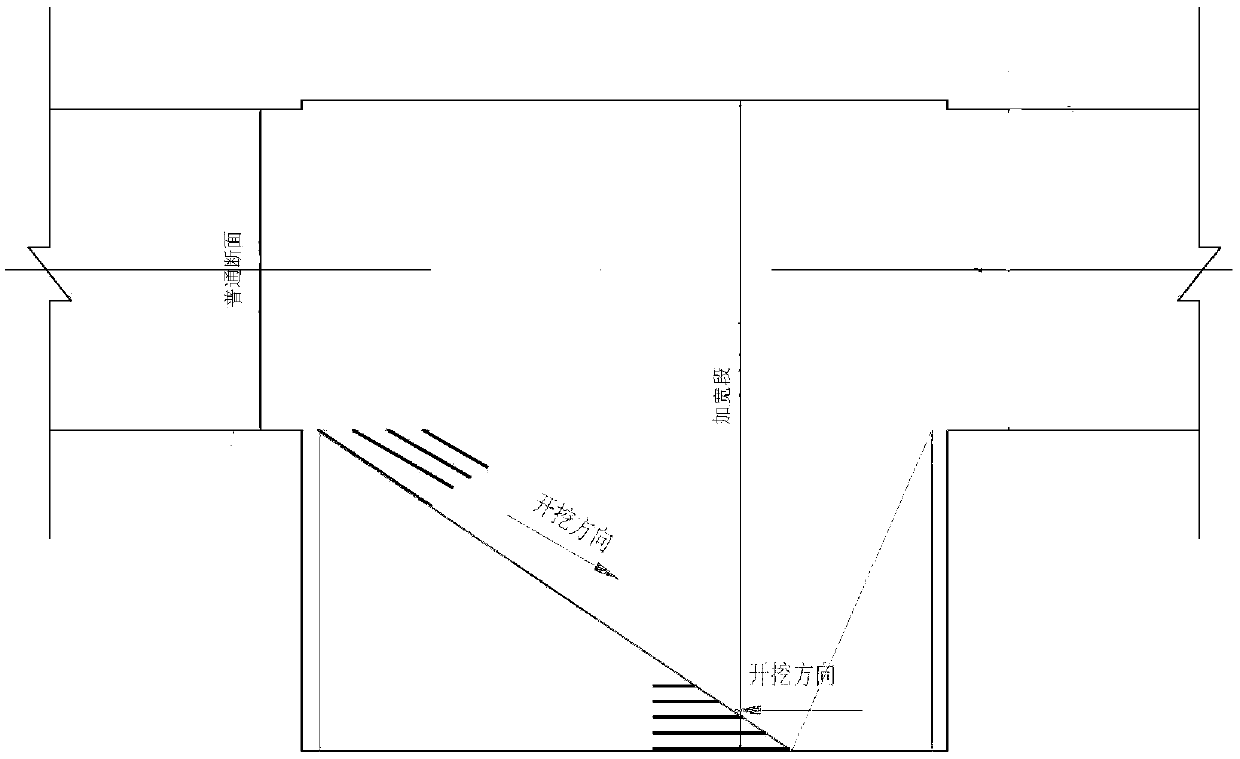

[0031] refer to Figure 1 to Figure 3 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto. The widening section mentioned below: a tunnel section set up in some traffic or pipeline tunnels and used as an escape lane or equipment installation space where one or more local sections are widened or heightened relative to the normal section size.

[0032] The invention provides a method for excavating by blasting and excavating a super-large and widened section of a tunnel, which comprises the following steps:

[0033] S10. Excavate the common section first, appropriately increase the camber angle of the blasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com