Strip steel deviation monitoring and diagnosing method and system for soaking pit of continuous annealing unit

A strip deviation and diagnosis method technology, applied in heat treatment furnaces, general control systems, control/regulation systems, etc., can solve problems such as false early warning of fault sources, inability to perform fault diagnosis, and installation of image monitoring devices to improve accuracy rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method and system for monitoring and diagnosing strip deviation of the soaking furnace of the continuous annealing unit of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

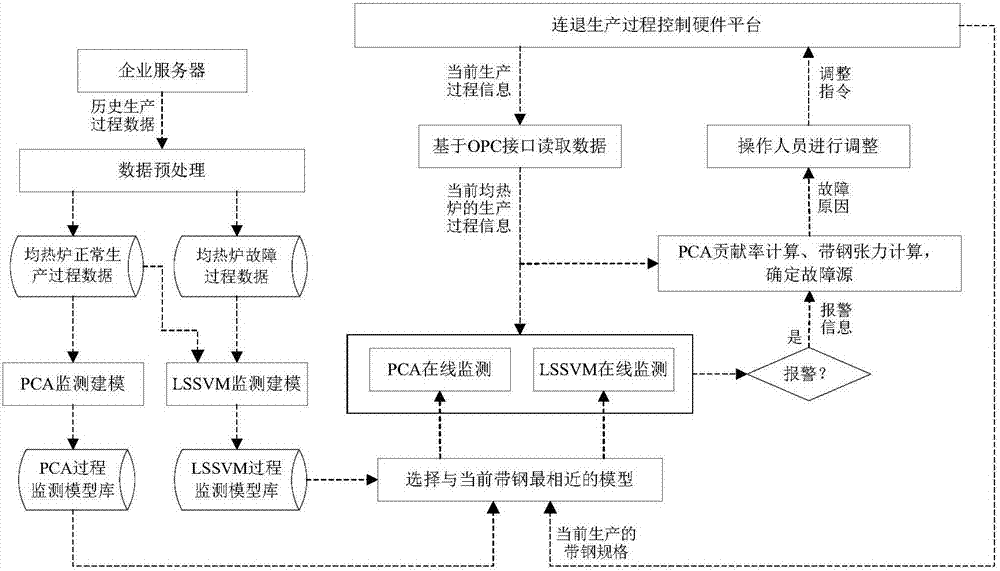

[0018] refer to figure 1 , the strip deviation monitoring and diagnosis method and system of the soaking furnace of the continuous annealing unit of the present invention, the basic flow of work is as follows: first, according to the historical data information of the enterprise, respectively establish the PCA and LSSVM monitoring models of the strips of various specifications; Then, during the real-time monitoring process, the process information data of the soaking furnace is read from the process control hardware platform of the continuous annealing production line through the OPC interface every small time interval, and the monitoring model is used to j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com