Preparation method of high-infrared emitting ability graphene/MnO2 porous material

A technology of infrared emissivity and porous materials, which is applied in the field of preparation of graphene/MnO2 porous materials with high infrared emissivity, can solve problems such as unreported, and achieves the advantages of easily available raw materials, simple preparation method and high far-infrared emissivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

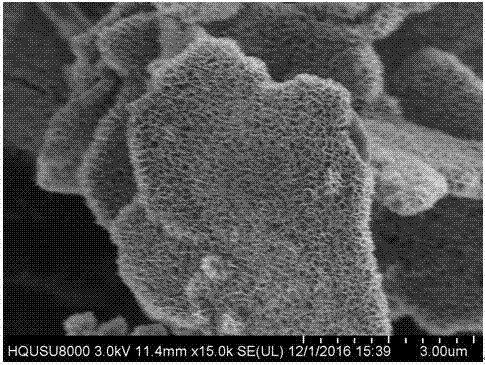

[0024] Example 1, see figure 1 :

[0025] The invention provides a high infrared emissivity graphene / MnO 2 A method for preparing a porous material, comprising the steps of:

[0026] 1) Put 0.2g of graphene powder prepared by mechanical exfoliation into a beaker, add 100ml of distilled water, and ultrasonically disperse for 40min to completely disperse the graphene;

[0027] 2) Add 1.4542g potassium permanganate to the solution in step 1), and continue ultrasonic dispersion for 30min;

[0028] 3) Move the mixed solution in step 2) into a hydrothermal synthesis reactor, put the reactor into a box-type atmosphere furnace, and conduct a hydrothermal reaction at 150°C for 6 hours;

[0029] 4) Suction filtration, washing several times with distilled water, and drying in an oven to obtain the product high infrared emissivity graphene / MnO 2 Porous material powder.

[0030] Scanning electron microscopy (SEM) was used to analyze the microscopic morphology of the product of this ex...

Embodiment 2

[0032] The invention provides a high infrared emissivity graphene / MnO 2 A method for preparing a porous material, comprising the steps of:

[0033] 1) Put 0.2g of graphene powder prepared by mechanical exfoliation into a beaker, add 100ml of distilled water, and ultrasonically disperse for 40min to completely disperse the graphene;

[0034] 2) Add 3.2719g potassium permanganate to the solution in step 1), and continue ultrasonic dispersion for 30min;

[0035] 3) Move the mixed solution in step 2) into a hydrothermal synthesis reactor, put the reactor into a box-type atmosphere furnace, and conduct a hydrothermal reaction at 150°C for 6 hours;

[0036] 4) Suction filtration, washing several times with distilled water, and drying in an oven to obtain the product high infrared emissivity graphene / MnO 2 Porous material powder.

[0037] After testing, the infrared emissivity of the product is 0.96.

Embodiment 3

[0039] The invention provides a high infrared emissivity graphene / MnO 2 A method for preparing a porous material, comprising the steps of:

[0040] 1) Put 0.1g of graphene powder prepared by mechanical exfoliation into a beaker, add 100ml of distilled water, and ultrasonically disperse for 40 minutes to completely disperse the graphene;

[0041] 2) Add 3.4537g potassium permanganate to the solution in step 1), and continue ultrasonic dispersion for 30min;

[0042] 3) Move the mixed solution in step 2) into a hydrothermal synthesis reactor, put the reactor into a box-type atmosphere furnace, and conduct a hydrothermal reaction at 150°C for 6 hours;

[0043] 4) Suction filtration, washing several times with distilled water, and drying in an oven to obtain the product high infrared emissivity graphene / MnO 2 Porous material powder.

[0044] After testing, the infrared emissivity of the product is 0.97.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com