Method for producing aromatic hydrocarbons and light olefins by converting methanol or dimethyl ether

A low-carbon olefin and dimethyl ether technology, applied in the field of circulating fluidized bed reaction-regeneration system, can solve problems affecting the continuous and stable operation of the device, hydrothermal deactivation of the catalyst, and reduction in the yield of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

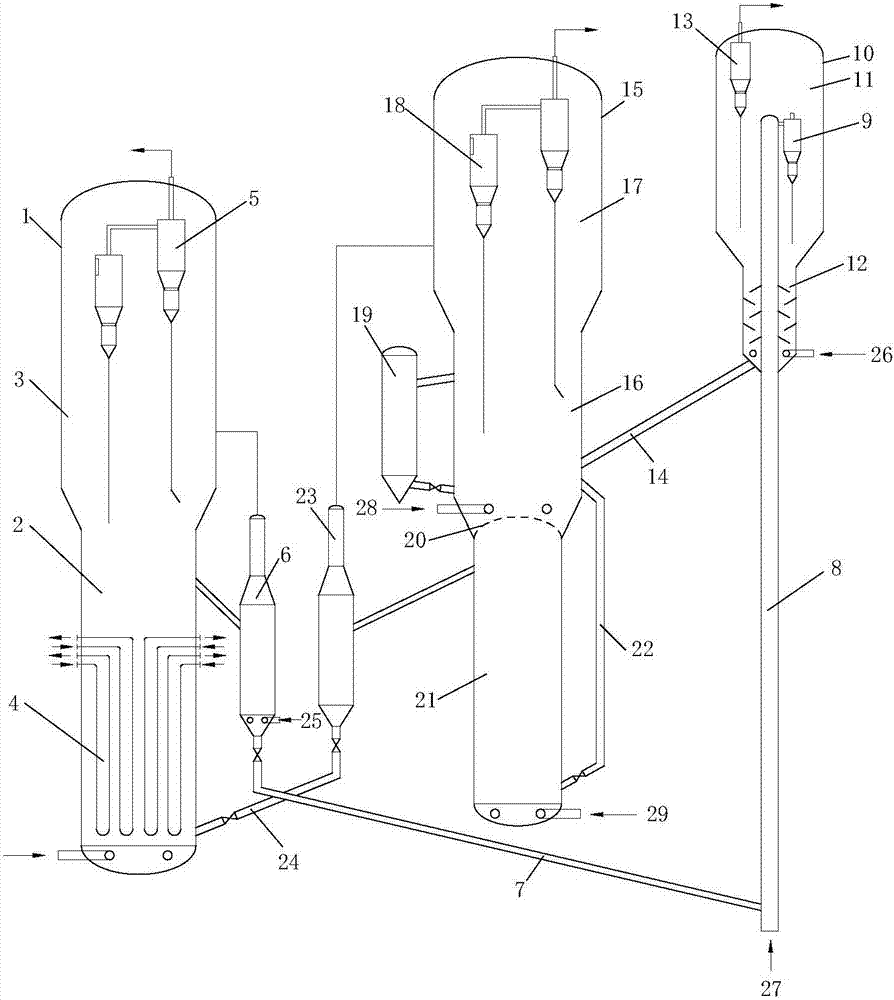

[0040] 1.8 million tons / year methanol production of aromatics and light olefins adopts such as figure 1 Shown is a circulating fluidized bed reaction-regeneration system. The fluidized bed reactor is equipped with an internal heat collector, and the metal catalyst 1%Zn / 3%La / ZSM-5 is used. The reaction process conditions of the fluidized bed reactor are as follows: the reaction temperature is 450°C, the reaction pressure is 0.3MPa, The average density of the catalyst in the dense phase zone is 300 kg / m 3 , the average empty tower line speed is 0.7 m / s. The regeneration process conditions of the fluidized bed regenerator are as follows: the secondary temperature is 550°C, the secondary pressure is 0.2MPa, and the average density of the catalyst in the secondary dense phase zone is 300 kg / m 3 , the average superficial linear velocity is 0.8 m / s; the secondary temperature is 680°C, the secondary pressure is 0.21MPa, and the average catalyst density in the secondary dense phase z...

Embodiment 2

[0043] 1.2 million tons / year methanol production of aromatics and low-carbon olefins adopts such as figure 1 Shown is a circulating fluidized bed reaction-regeneration system. The fluidized bed reactor is equipped with an internal heat collector, and the metal catalyst 1%Zn / 3%La / ZSM-5 is used. The reaction process conditions of the fluidized bed reactor are: the reaction temperature is 480°C, the reaction pressure is 0.3MPa, The average density of the catalyst in the dense phase zone is 380 kg / m 3 , the average empty tower line speed is 0.8 m / s. The regeneration process conditions of the fluidized bed regenerator are as follows: the secondary temperature is 530°C, the secondary pressure is 0.3MPa, and the average density of the catalyst in the secondary dense phase zone is 350 kg / m 3 , the average superficial linear velocity is 0.6 m / s; the secondary temperature is 690°C, the secondary pressure is 0.31 MPa, and the average catalyst density in the secondary dense phase zone i...

Embodiment 3

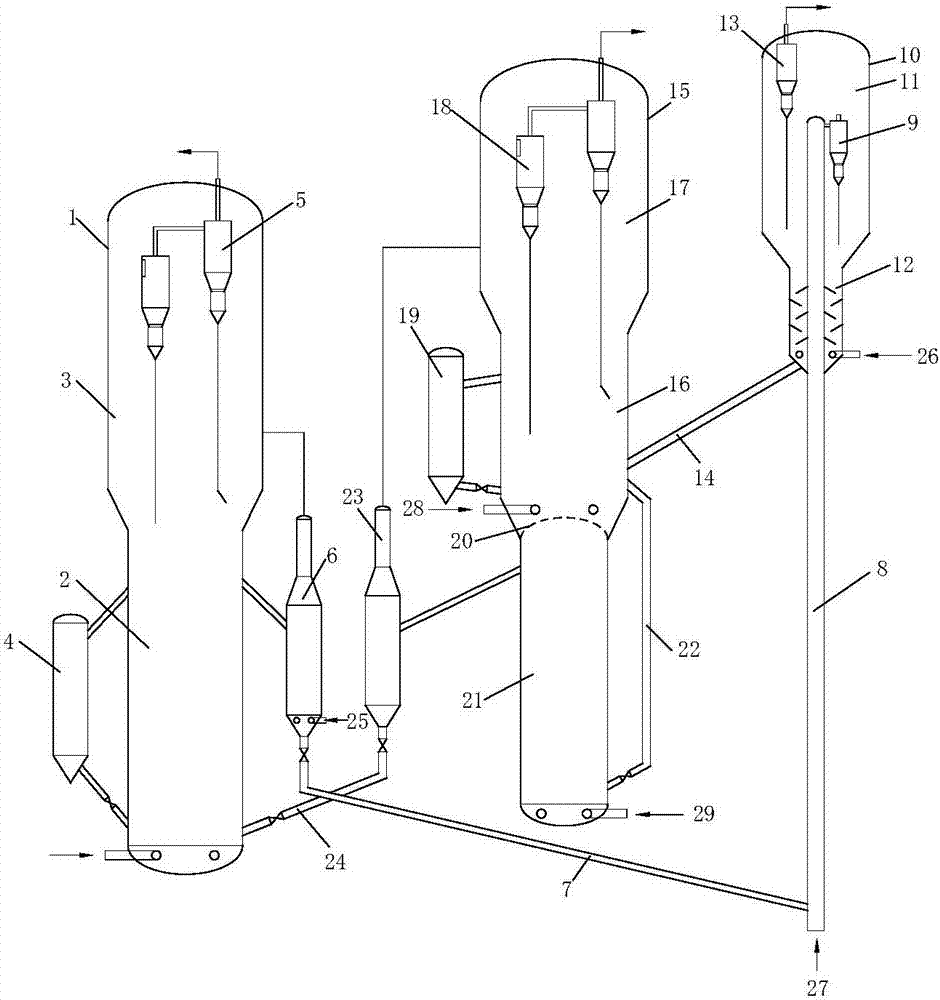

[0046] 1.8 million tons / year methanol production of aromatics and light olefins adopts such as figure 2 In the circulating fluidized bed reaction-regeneration system shown, the fluidized bed reactor is equipped with an external heat collector, and a metal catalyst 1%Zn / 3%La / ZSM-5 is used. Using Zn-Mg-ZSM-5 catalyst, the reaction process conditions of the fluidized bed reactor are as follows: the reaction temperature is 490 ° C, the reaction pressure is 0.2 MPa, and the average density of the catalyst in the dense phase zone is 430 kg / m 3 , the average superficial velocity is 0.9 m / s. The regeneration process conditions of the fluidized bed regenerator are as follows: the secondary temperature is 560°C, the secondary pressure is 0.2MPa, and the average density of the catalyst in the secondary dense phase zone is 250 kg / m 3 , the average superficial linear velocity is 0.8 m / s; the secondary temperature is 680°C, the secondary pressure is 0.21MPa, and the average catalyst densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com