Boil-off gas treatment system

一种蒸发气体、处理系统的技术,应用在蒸发气体处理系统领域,能够解决浪费BOG化学能等问题,达到简单维护及修理、降低初始安装成本、实现多样化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

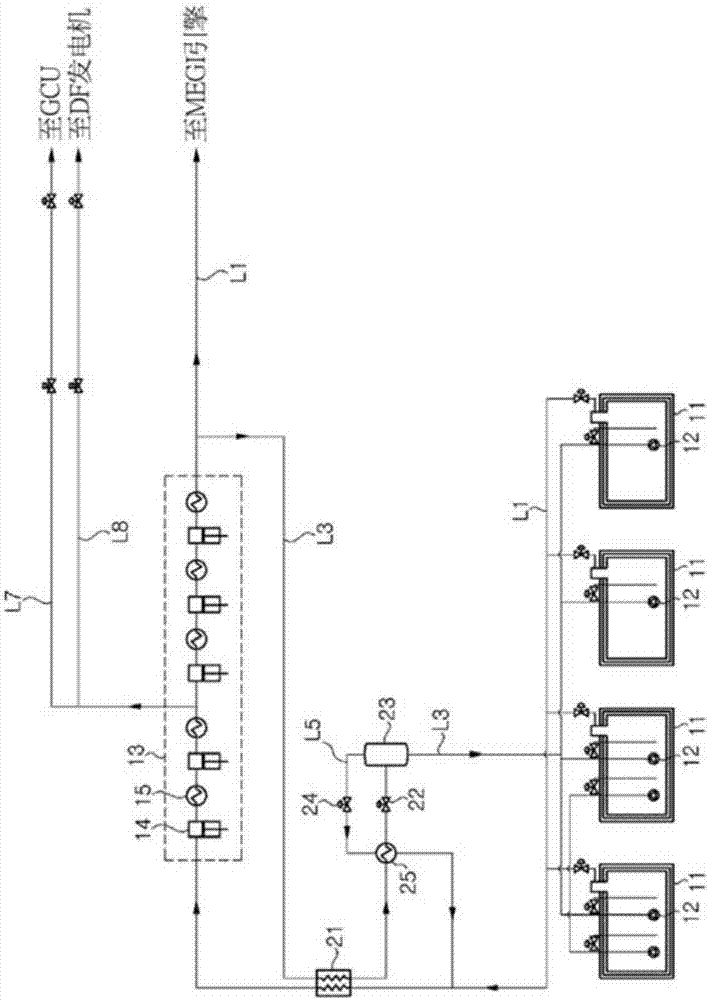

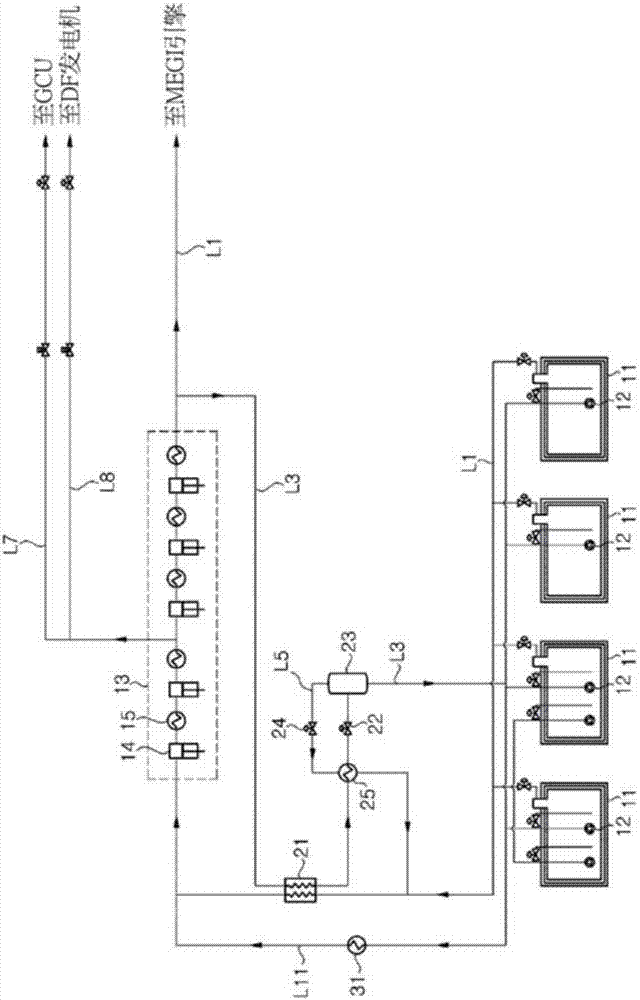

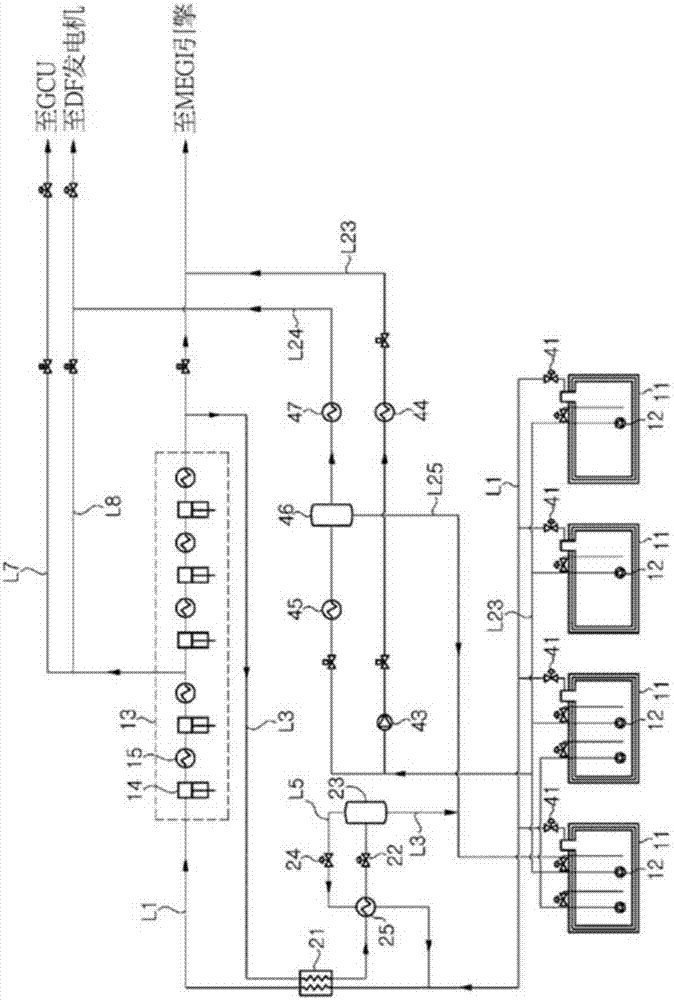

[0042] The above and other aspects, advantages and objects of the invention will become apparent from the accompanying drawings and the following description of exemplary embodiments of the invention.

[0043] Hereinafter, exemplary embodiments of the present invention will be explained in detail with reference to the accompanying drawings. Throughout the drawings, the same components will be denoted by the same reference numerals.

[0044] In general, the International Maritime Organization regulates nitrogen oxides (NO X ) and sulfur oxides (SO X ) emissions, and recent attempts to regulate carbon dioxide (CO 2 ) emissions. Specifically, for nitrogen oxides (NO X ) and sulfur oxides (SO X ) was raised in 1997 by the Agreement on the Prevention of Marine Pollution from Ships (MARPOL; The prevention of Maritime Pollution from Ships). Eight years later, the agreement fulfilled the requirements for implementation and entered into force in May 2005, and the regulation is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com