Rotary fixing device for cylindrical sleeve body polishing mechanism

A polishing mechanism and fixing device technology, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding/polishing equipment, etc., can solve problems such as troublesome installation and fixing, affecting the quality and effect of polishing, and low efficiency. Achieve good effect, convenient manual polishing or automatic polishing, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

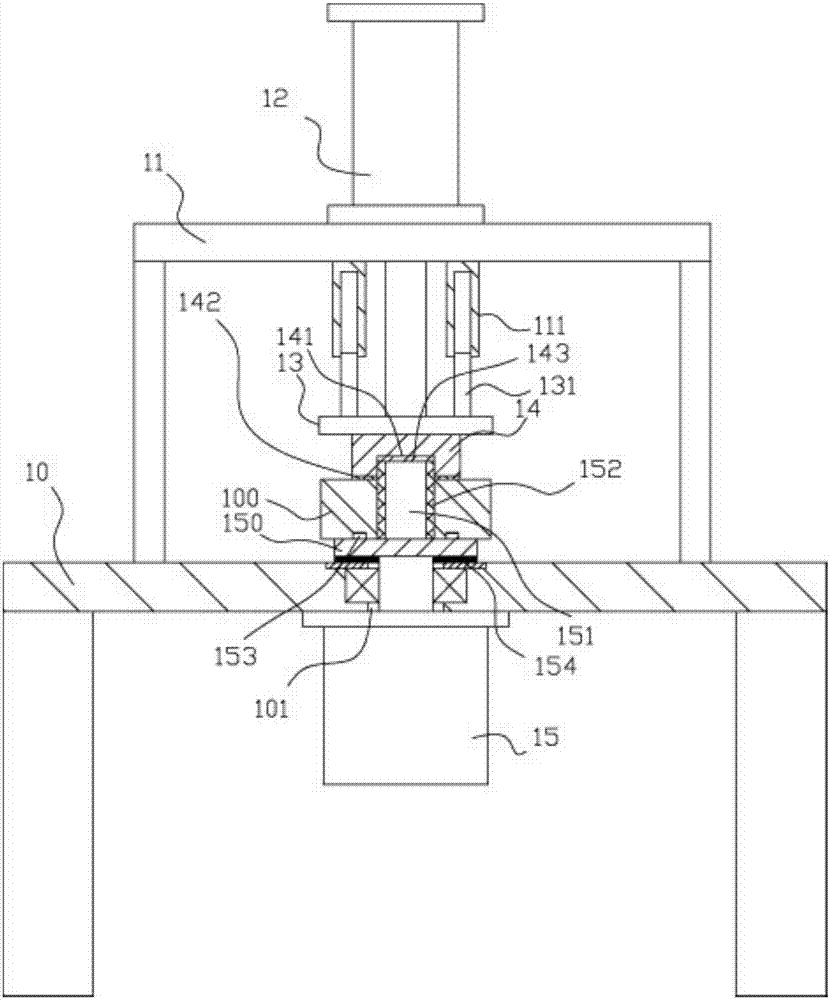

[0013] Example: see figure 1 Shown, a kind of rotary fixing device for cylindrical body polishing mechanism, comprises frame 10, and the top surface of the top plate of described frame 10 is fixed with upper supporting frame 11, and the middle part of the top plate of upper supporting frame 11 is fixed with elevating cylinder 12 , the push rod of the lifting cylinder 12 passes through the top plate of the upper support frame 11 and is fixed with a lifting plate 13, the middle part of the bottom surface of the lifting plate 13 is fixed with an upper pressing block 14, and the middle part of the bottom surface of the upper pressing block 14 has a jack 141 The bottom surface of the middle part of the top plate of the frame 10 is fixed with a rotary motor 15, the output shaft of the rotary motor 15 is inserted into the main center through hole 101 in the middle of the top plate of the frame 10, and the end of the output shaft of the rotary motor 15 is fixed. There is a horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com